By Kingsley Clarke, SCF Framework Operations Lead

The Public Sector Decarbonisation Scheme has now launched, which will support the aim of reducing emissions from public sector buildings by 75% by 2037. It will provide over 1.5 billion of grant funding up until 2026 to support public sector organisations which are facing pressure to deliver carbon savings and meet upcoming Net Zero targets.

Eighty percent of UK buildings that will exist in 2050 have already been built, and while it might seem easier to develop new buildings which meet sustainability targets, the opportunity to retrofit existing building stock to ensure they meet climate change targets can’t be ignored.

With the built environment sector accounting for 40% of all carbon emissions released, there is a growing awareness around whole life carbon and ensuring that we are using less carbon for the whole lifecycle of a building.

In support of our public sector partners, SCF has set up the SCF Climate & Sustainability Working Group, a collection of contractor representatives with expertise in carbon reduction and sustainability. It is their job to monitor developments in legislation and best practice and in this article, we have taken their insight to support you to make informed decisions about retrofit.

With many universities and schools pledging to become carbon zero by 2030 or 2050, is the greenest building always the one that already exists and what challenges do educational establishments face when considering carbon retrofit?

To build or not to rebuild? The issue of historic buildings

Universities and schools are some of the most historic buildings in the UK so retrofitting them presents a complex challenge. According to Historic England, older buildings require a special approach as they take up moisture from their surroundings and release them according to environmental conditions, heating up and cooling down more slowly. This equilibrium can be affected when changes are made to increase energy efficiency and can have adverse consequences such as moisture accumulation or overheating.

Each historic building is unique, and despite the potential carbon cost, it might not be appropriate to retrofit due to structural or design issues – in which case a rebuild may be the better option.

By ensuring due diligence is done and processes such as a two-stage open book is undertaken via frameworks such as SCF, this will enable building risks to be assessed early on, allowing the entire ecosystem to be considered.

If suitable however, retrofit can make a huge difference to carbon reduction. A heat pump can reduce carbon emissions by up to 70% compared with a gas boiler and The UK Committee on Climate Change has highlighted the need to speed up their deployment. But proper insulation needs to be in place or viable as an option for this efficiency to be maintained, so it’s important that this is assessed on a case-by-case basis.

Safety considerations must also be considered. Retrofitting can serve to address the need for repairs faced by some schools and universities across the country, including asbestos removal. But it might be the case that the entire building is unfit for use due to structural safety issues, in which case a rebuild will need to be undertaken.

Are your buildings retro(fit) for the future?

Retrofitting existing buildings presents an educational opportunity to pupils, creating a dialogue about sustainability between students, local authorities, and teachers. With a skills shortage in retrofit, schools, colleges, and higher education institutions have a part to play in inspiring future generations to consider the importance of sustainable buildings.

Biodiversity is also a key factor to consider. With the biodiversity net gain rules coming into effect in November 2023, it’s worth thinking about retrofit as an option as this will ease the biodiversity commitments due to the lessened impact on site.

Another key consideration is whether existing educational buildings are sufficient to meet the needs of the future student population. According to a report by the Office for Students, UK’s higher education population is expected to grow by 12.3% by 2025, increasing the requirement for additional campus buildings. Contractors can therefore work closely with universities to ensure they are meeting sustainability targets in future buildings when retrofit simply doesn’t meet future spatial requirements.

Recently, SCF contractor Galliford Try built a new state-of-the-art tech park at Chichester University to provide new engineering and digital creative technology facilities to support 500 new undergraduate and postgraduate student places per year. Passivhaus design principals were applied resulting in running costs efficiencies.

What are the cost considerations?

Retrofitting is not a quick fix to rising energy bills, but in the long run modifications to a heating system will improve a building’s lifetime running costs while reducing energy consumption. The House of Commons Library estimates that schools’ energy bills have risen by 93% in the last year, so retrofitting can enable schools and universities to make much needed savings.

However new buildings may reduce the need for future repairs, while also reducing carbon to the extent that the original embodied carbon emitted during the build process will be offset.

One size doesn’t fit all

The issue of whether educational institutions should take a retrofit first approach is complex. Each has its own goals and barriers. However, with the National Audit Office estimating that 60% of current educational building stock was constructed before 1976 when sustainability concerns were not as much of a priority, it’s important that this imbalance in addressed.

Whether or not to retrofit, shouldn’t be a binary decision, or one which is made in isolation. The environment is a huge issue for students today and will continue to increase in importance as the impact of climate change accelerates. It’s important that solutions are chosen that will do the best by planet and people.

CLICK HERE TO VISIT THE SOUTHERN CONSTRUCTION FRAMEWORK WEBSITE

to any and all domestic properties or small businesses that need instant, economic and temperature-controlled volumes of hot water. The temperature range for all three models is between 37-65 degrees centigrade making them ideal for comfortable ablutions and heavy-duty high volume commercial cleaning for instance in restaurants where high temperature can cut through oil and grease.

to any and all domestic properties or small businesses that need instant, economic and temperature-controlled volumes of hot water. The temperature range for all three models is between 37-65 degrees centigrade making them ideal for comfortable ablutions and heavy-duty high volume commercial cleaning for instance in restaurants where high temperature can cut through oil and grease.

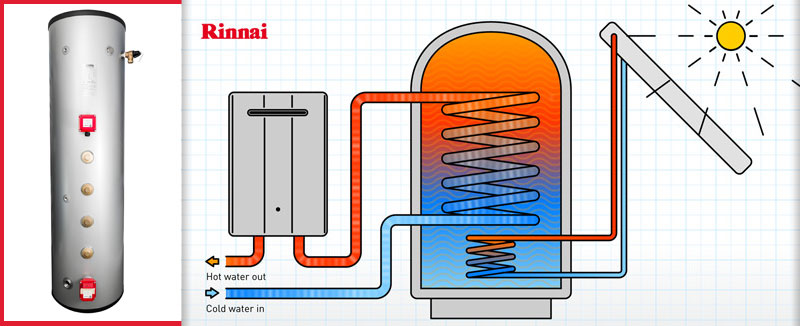

As the UK is now firmly in an era of energy transition it is important that all interested parties – heating engineers, contractors, consultants and end-users – should be aware of what alternative energy is currently available and future options being actively considered.

As the UK is now firmly in an era of energy transition it is important that all interested parties – heating engineers, contractors, consultants and end-users – should be aware of what alternative energy is currently available and future options being actively considered.