ALTRO ADDS COLOUR TO REJUVENATED WAITING AREA AT SHEFFIELD CHILDREN’S HOSPITAL

A chance hospital visit resulted in a refurbishment of the Emergency Department waiting area at Sheffield Children’s Hospital, using Altro floors and walls and delivered at no cost to the hospital.

Over the last two years the NHS has faced unprecedented challenges that have made the British public more appreciative than ever of our health services, with more and more people wanting to give something back. When Ryan Spencer took his son to A&E for treatment, it set off a series of actions resulting in a rejuvenated waiting area that has made a huge difference to families and staff alike.

Ryan Spencer runs RLX Construction, but in 2020 he worked for Henry Boot Construction, a Sheffield-based company with a background in healthcare projects. Ryan explains how the project at Sheffield Children’s Hospital came about: “I took my son to A&E and as we waited, I though this is a great facility that has served so many children, but it was really looking a little tired, and a little outdated.

“So, I approached my employer with the idea of giving something back – using our contacts and experience, asking our subcontractors to work with us at a reduced price for this project, and asking our manufacturers to donate products. I got really good buy-in, and we were able to deliver a fresh, bright and colourful waiting area at no cost to the hospital.”

The Altro Whiterock walls were installed by Richardson Claddings. Fresco Flooring installed the Altro floors.

Jamie Douglas, Senior Capital Projects Manager at Sheffield Children’s Hospital, was delighted with the project, especially as it used products from tried and trusted manufacturer Altro. “We use Altro products across the hospital,” Jamie explains. “This project used Altro Fortis Titanium wall protection, and Altro Whiterock Chameleon and Altro Whiterock Satins – we know these well and use them a lot.

“For flooring, we tried something new – Altro Cantata adhesive-free floors. This was recommended to us because it is so quick to install, with little disruption. This is essential in busy areas such as these where we cannot afford downtime. We had not used adhesive-free flooring before but it is very impressive and we will certainly look to use Altro Cantata in other projects in the future.”

Ryan Spencer worked with Altro to put forward suitable products to the hospital’s art team who viewed swatches and colour palettes to make the final selections. The results are making a big difference to staff and to the families using the services, as Dr Cath Rimmer, Paediatric Emergency Medicine Consultant and ED Team Lead, explains: “The whole place looks so much better. It’s clean, fresh, and bright. It’s a far more pleasant environment to wait in for children and families attending the emergency department.”

Ryan Spencer was also delighted with the results. “It was not just about looks; this project had to deliver performance too. We opted for Altro Cantata because it could be laid over the existing flooring in this area that is in use 24/7, 365 days a year. The Altro wall products are fantastic because they bring colour and interest to the area with no compromise on hygiene and are so easy to clean.

“Our thanks to Altro for their help with this project. We use their products because they look great, they last a long time, but also because of the high quality customer service that backs that up.”

Altro Cantata™ is a tonal and modernist, adhesive-free floor that creates maximum impact with minimum downtime. It has been designed for hard-working public areas and is a durable 2.4mm floor. It gives you 14dB impact noise reduction, to quieten busy spaces, plus comfort under foot to help reduce fatigue. It is ideal for busy spaces where disruption needs to be minimal, is easy to clean and maintain and has no associated adhesive odours. At the end of its life can be removed easily, allowing it to be reused or recycled.

Altro Fortis Titanium™ offers durable protection for walls, doors and corners. Doors and plaster board walls can easily be damaged, be it scrapes and knocks as people pass, or more serious dents and holes caused by wheeled traffic. Altro Fortis Titanium has been specifically designed to protect these surfaces and is dense, impervious and resistant to bumps. It features a lightly textured surface, which camouflages scuffs, keeping the wall area looking better for longer.

Suitable for busy public areas that are subject to high levels of traffic such as in education and healthcare, Altro Fortis Titanium is impervious and easy-to-maintain and co-ordinates with Altro Fortis corner protection.

Altro Whiterock Satins™ is a range of colourful, satin finish wall sheets with all the hygiene and durability of Altro Whiterock. Versatile and sophisticated, vary the mood to stimulate or soothe. Great in wet environments, wards and kitchens. Altro Whiterock Satins can be combined with Altro non-sparkle safety flooring to achieve the required Light Reflectance Value difference needed for the requirements of the Equality Act 2010.

Altro Whiterock ChameleonTM is glossy, vibrant and vividly colourful hygienic wall cladding, available in 16 high impact, high-design shades to add a little bit of affordable luxury to a range of environments. Offering all the benefits of Altro Whiterock, Altro Whiterock Chameleon is very durable, with a smooth, watertight, wipe-clean surface.

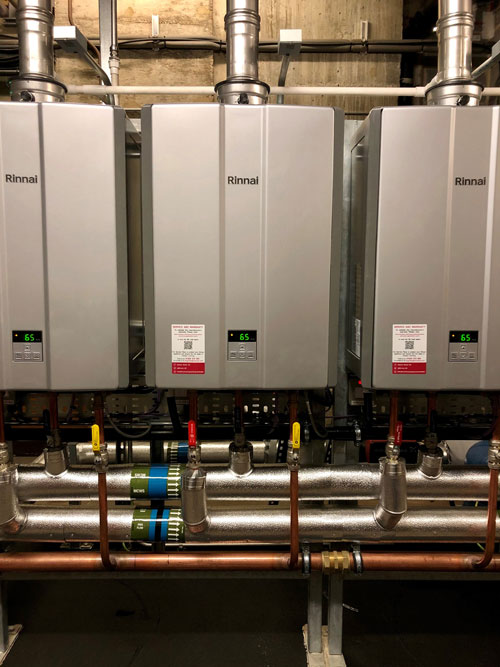

Says Chris Goggin, Operation Director for Rinnai, ’Our company operates on the five continents of the world producing over 2 million water heating units each year. We have a global reach of over 650 design engineers plus testing facilities in Japan, America and Australasia. We have moved this quickly as we perceive that the market is fast changing.

Says Chris Goggin, Operation Director for Rinnai, ’Our company operates on the five continents of the world producing over 2 million water heating units each year. We have a global reach of over 650 design engineers plus testing facilities in Japan, America and Australasia. We have moved this quickly as we perceive that the market is fast changing.

Whilst this new fuel is entirely compatible with conventional diesel equipment and actually contributes to engine longevity, it is not without additional cost, but Managing Director, Christian Watson stands committed to this move.

Whilst this new fuel is entirely compatible with conventional diesel equipment and actually contributes to engine longevity, it is not without additional cost, but Managing Director, Christian Watson stands committed to this move.

Once the Bath and North East Somerset planning department was happy with Bloor’s proposal to use Modus windows in Hazy Grey, it gave the go-ahead for the same product range, but in Agate Grey, to be used at an adjacent development from the other housebuilder.

Once the Bath and North East Somerset planning department was happy with Bloor’s proposal to use Modus windows in Hazy Grey, it gave the go-ahead for the same product range, but in Agate Grey, to be used at an adjacent development from the other housebuilder.

To provide specifiers with additional confidence, Lindapter commissioned BRE Global to run third party fire tests in accordance with BS EN 1991-1-2 on a range of Decking Fixings installed in concrete backed composite decking profiles. The BRE test report P116310 Issue 1 verifies load limits for 60 minute and 90 minute fire ratings.

To provide specifiers with additional confidence, Lindapter commissioned BRE Global to run third party fire tests in accordance with BS EN 1991-1-2 on a range of Decking Fixings installed in concrete backed composite decking profiles. The BRE test report P116310 Issue 1 verifies load limits for 60 minute and 90 minute fire ratings.