The Daily Star and KSRM (Kabir Steel Re-Rolling Mills Limited) jointly organised an online discussion titled “Green Construction – The Future of the Industry” on June 5, 2021. Here we publish a summary of the discussion

We are always surrounded by concrete because it is the most common building material. Even now, all of us are sitting on and are surrounded by concrete. The main ingredient for making concrete is cement. Every tonne of cement produces a tonne of carbon dioxide. Seeing that globally we use four billion tonnes of cement annually just gives you an idea of the scale of pollution from concrete production alone. That is 10 percent of the global carbon dioxide emission.

In Bangladesh, our consumption of cement is much lower than the global average. But we still have to do better. Green construction requires two things primarily: more efficient use of energy in construction work and more sustainable and environmentally friendly building materials. Water efficiency and waste management are also very important.

Going forward, we have to think about all these factors. Ensuring that our construction work and buildings become more sustainable also plays into the sustainable development goals that we are targeting as a country. We need to ensure the future generations can continue to enjoy life as we were able to once, and the only way to do that is by becoming more environmentally conscious in all aspects of our lives.

Dr Md Tarek Uddin,

PEng., Professor, Department of Civil and Environmental Engineering (CEE), Islamic University of Technology (IUT)

Historically, a consequence of development has been the deterioration of the environment and the surrounding ecology. The more our lives flourish, the more the environment suffers as a consequence. This is why Dhaka is one of the most polluted cities in the world because a consequence of its fast development has been the negative effects on the environment.

There are a lot of roads in the country that have been built based on the plans and geometric estimations from over 100 years back. We have continued to widen these roads instead of rethinking their overall construction. There are certain roads that are over 200 kilometres in length, but in the current landscape, they perhaps should not be more than 180 kilometres.

We need to use alternatives to bricks in the construction of buildings and roads such as Compressed Stabilized Earth Blocks (CSEB), Interlocking CSEB, Concrete Hollow Block (CHB), Thermal Block (TB), and Aerated Concrete and Ferro-cement Sandwich Panel (ACFSP).

Engineer S M Khorshed Alam,

President, Bangladesh Association of Construction Industry (BACI)

The main idea behind green construction is sustainability. Firstly, construction must take environmental issues into consideration so that the next generation does not suffer due to our actions. Secondly, structures have to be durable. Even if the environmental impact of a less durable structure is low, it can’t be considered sustainable. Thirdly, construction projects have to be affordable. And lastly, the use of construction materials has to be minimised.

If we want to boost green construction, we must adopt the concept of life-cycle analysis. According to life-cycle analysis, structures with a longer life are considered cheaper even if their monetary cost is slightly higher. The total maintenance cost throughout the life of a structure is included in the life-cycle costs. The concept of social cost analysis also has to be incorporated into the cost analysis of construction products. The environmental load of a construction product is added to the commodity value to give us the social cost. We are set to fail in achieving the relevant sustainable development goals (SDGs) by 2030 because we have yet to incorporate life-cycle and social cost analysis concepts into green construction.

Bangladesh’s carbon emission is about 100 million tonnes per year. If the construction sector is responsible for one-third of this emission, it means it emits 33 million tonnes. Of this, brick production alone contributes 20 million tonnes. Bangladesh has a commitment under the 2015 United Nations Climate Change Conference, COP 21, to reduce carbon emissions by 20 percent by 2030. If we stop using bricks as construction materials, we can reduce carbon emission by close to 20 percent. 300 grams of carbon emission are produced per kilogram of brick. But, concrete blocks only emit 100 grams of carbon per kilogram. Therefore, by shifting from bricks to concrete blocks, the entire sector can reduce two-thirds of the current carbon emissions.

One kilogram of cement is responsible for one kilogram of carbon emission. One kilogram of rod produces half a kilogram of carbon emission. Therefore, cement and rod consumption has to be reduced. We also have to reduce carbon emissions in the cement and rod production process by using advanced technology.

Stone aggregate, which is coarse aggregate, is a mandatory construction material that is fully imported. Green construction encourages the usage of local materials. Since there are no alternatives to stone aggregate, its use has to be decreased to be sustainable.

Ferro-cement technology can help reduce building material consumption and carbon emissions and increase affordability and structure durability.

Md Abu Sadeque,

PEng., Executive Director, HBRC

The world is constantly growing through new technology and research. By the time we make decisions about the planning for green construction, construction practices will have changed yet again. We have entered the Fourth Industrial Revolution, and the construction industry will change drastically over the next five to 10 years. We are expecting to move towards mechanised and automated construction involving 3D-printed buildings and bridges. Highly skilled workers will manage and drive the robotic arms of these 3D printers, which may result in low-skilled workers losing their jobs. Therefore, many unskilled workers will have to develop skills to sustain themselves economically.

The overall result of these new initiatives will be that these durably constructed facilities will be delivered at a faster pace for the people. Our future infrastructure will be interconnected, with an obvious blending of civil engineering, IT infrastructure and communication networks. We need to demonstrate the effectiveness of this connectivity at the operational level. To achieve this goal, appropriate thoughts should be present during planning and designing, as well as when construction is started, to help Bangladesh remain on par with the rest of the world.

Quite a bit of research in Bangladesh has explored the benefits of recycling construction materials, but this topic has not yet been firmly included in our national construction policies and guidelines. We have a great deal of country-specific research, and we must put the findings into practice through entrepreneurship development. Gradually, many recycling industries will develop and will work with recycling technologies. Gradually, many startup businesses will emerge and prosper around these new industries. Then, perhaps, recycling industries will be established to recycle polymers, steel, bricks, and concrete and to help grow recycling-based startups. These businesses will transform the construction sector by reducing its carbon footprint. Ultimately, we will be able to advance in the field of green construction. We must come forward in support of this idea and work dedicatedly to implement such policies.

We must reduce the need for maintenance efforts, life-cycle costs and carbon footprints in all construction processes. We also need to think about how waste will be managed after demolition. The design stage must have plans for all of these aspects. Country-specific research outcomes concerning innovations in new materials, construction, operation and maintenance science should be included comprehensively in textbooks and curriculum. The findings of such studies should be implemented through entrepreneurship development. The industry must come to the door of the academics and students, or vice versa. Industry advisory panels at higher learning institutions for engineering must be active and effective.

A F M Saiful Amin,

Professor, Department of Civil Engineering, BUET

Life cycle management is a crucial part of a project. Every developed country has a policy for life cycle management of projects. We need to minimise the cost of a project by maximising its service life. The initial cost might be higher but it will benefit us in the long term. So, we need a good policy for the assessment of a building’s life cycle.

Material efficiency is another major part of a project. We need to think carefully about the usage of material, for example, ordinary cement. It produces a huge amount of carbon dioxide. We can reduce the emission of carbon dioxide by using mineral-based cement instead. But the concept is not very popular in Bangladesh at present. We need to provide guidelines in our academic courses about the benefits of using mineral-based cement and also make it more cost-efficient.

Dr Md. Tarek Uddin,

PEng., Professor, Department of Civil and Environmental Engineering (CEE), Islamic University of Technology (IUT)

An important aspect of green construction is sustainable construction. Two major parameters that have been addressed to achieve the SDGs are recycling and renewable energy. But the main focus should be how much we can implement at the policy level. We need to use renewable energy in our construction process and make sure we are reusing the materials from construction. We need to ensure the implementation of it at the government level. In this way, a large industry will develop around this and it will leave a noticeable impact on our economy.

Engineer S M Khorshed Alam,

President, Bangladesh Association of Construction Industry (BACI)

The term “carbon footprint” is internationally recognised. The systematic measurement of the carbon footprint of a person, organization or state, for use in carbon emissions trading, is termed a “carbon audit.” Each company must have a carbon audit system, which can be a basis for identifying eligible companies and establishing them as benchmarks. Such systems will be used to audit the rates of carbon emissions and absorption to estimate the net carbon footprint. All building has a carbon footprint, and the construction industry must aim to reduce this footprint from the very onset of planning. By taking small steps, we will be able to minimise our country’s industrial carbon footprint, create spaces for our vital agro-economy and reach internationally accepted levels. The government can provide incentives for pioneering companies, if necessary. All will go toward reducing our long-term environmental costs. If we keep damaging our environment, and if it takes an irreversible turn, we will be unable to save it. Therefore, we must cultivate awareness before it is too late. In this regard, our policymakers, engineers, construction industry leaders, environmentalists and designers must come together and work in unison.

A F M Saiful Amin,

Professor, Department of Civil Engineering, BUET

If we consider a building, 80 percent of its carbon emission comes from embodied energy. Embodied energy is the carbon emission rate while constructing building materials. The rest of the 20 percent is operating energy. Using renewable energy is part of operating energy. If we focus on brick construction, it accounts for around 58 percent of the total pollution of Dhaka city, which is a kind of embodied energy. If we use concrete blocks instead of bricks, we will be able to minimise carbon emission along with the cost. So it is clear that we must focus on embodied energy.

We import 100 percent of stones whereas we can produce artificial stones in the country using our resources. Some countries are using sand from their riverbeds. We also studied this process and it is possible. We can produce artificial blocks from sand that can withstand 8000 pounds per square inch of pressure. Then we can break these blocks to create artificial stones. This will help reduce the cost of importing and therefore pave the path towards more affordable and sustainable buildings.

Md Abu Sadeque,

PEng., Executive Director, HBRC

Source: DailyStar.Net

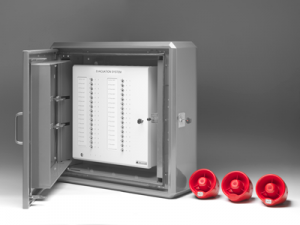

Advanced is a world leader in the development and manufacture of intelligent fire systems. Advanced’s reputation for performance, quality and ease of use sees its products specified in locations around the world, from single-panel installations to large, multi-site networks. Advanced’s products include complete fire detection systems, multiprotocol fire panels, extinguishing control, fire paging, false alarm management and reduction systems as well as emergency lighting.

Advanced is a world leader in the development and manufacture of intelligent fire systems. Advanced’s reputation for performance, quality and ease of use sees its products specified in locations around the world, from single-panel installations to large, multi-site networks. Advanced’s products include complete fire detection systems, multiprotocol fire panels, extinguishing control, fire paging, false alarm management and reduction systems as well as emergency lighting.