To celebrate ‘Plastic Free July’, Insulation Express has uncovered five ways on buildingspecifier.com that the construction industry can lessen its plastic consumption on a day-to-day basis:

Every year the UK uses over 5 million tonnes of plastic – that’s about 15 times as heavy as the Empire State Building. But did you know the construction industry accounts for a quarter (23%) of the plastic consumed in the UK? The construction industry is still heavily reliant on plastic, for its cheapness, durability and water-resistance making it the second largest consumer of plastic in the UK.

However, what makes plastic so useful for construction is also part of its demise. The resilience of plastic means it can take up to 1000 years to decompose, while it degrades it contaminates our soils and oceans with the release of fossil fuels and greenhouse gases. So, how can the industry lessen its plastic footprint?

The most common sources of plastic waste in construction

When plastic is used in a permanent form, it can be vital as a building material. However, when the material is single-use plastic, this becomes a bigger problem, that’s wasteful and can be easily avoided. These are the most common sources of plastic waste in construction:

- Plastic packaging (which accounts for 25% of packaging waste in construction).

- Unused materials from over ordering and off-cuts.

- Improper storage and handling.

- Over-specified project design.

- Workforce food packaging and utensils.

Annually, 50,000 tonnes of plastic packaging waste is produced by the UK’s construction industry

It’s believed the construction industry has an effective management of plastic waste, but the picture is not as transparent. The British construction industry generates 50,000 tonnes of plastic packaging waste per year – that’s four times the weight of The Brooklyn Bridge. Much of that plastic waste is incinerated, adding toxic fumes to the air we breathe. Other large amounts of plastic are placed in mixed waste skips which is impossible to recycle, because they can’t be identified, or they are contaminated with other materials. This has helped to contribute to 5 trillion micro-plastic particles floating in oceans, which we then consume through water or from fish.

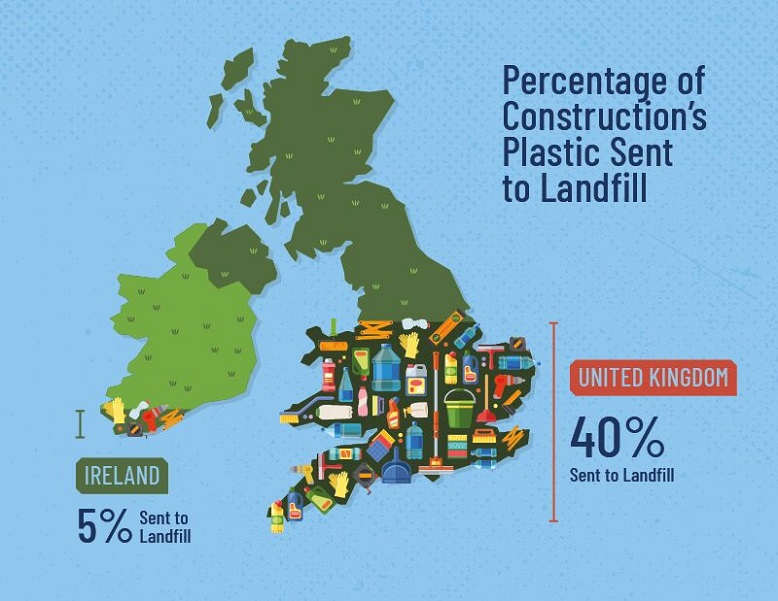

40% of plastic waste from construction in the UK is sent to landfill

It’s estimated that large quantities of plastic leave construction sites in mixed waste skips – sending 40% (20,000 tonnes) of plastic to landfill, a weight that is twice as heavy as The Eiffel Tower.

On the other end of the scale, Germany recovers and recycles a huge proportion of the plastic waste created in construction. In total, Germany generates 201.8 million tonnes of waste in construction and demolition, but around 90% of that is recycled, and around 80% of the plastic waste is recycled.

How construction can reduce plastic packaging waste in construction

Research reveals that a huge third of single-use packaging leaving sites is single-use packaging. Shockingly, only 2-4% of this is recycled. The rest is diverted to landfill, fly-tipped, or burnt. It is clear that the amount of plastic being sent to landfill is not sustainable for either the environment or construction.

Most of the industry realises something needs to change, with 95% of construction professionals admitting that the industry needs to reduce plastic use. But, how can this be achieved?

- A huge proportion of packaging thrown away can often be reused. You can talk with your supplier to see if they can reduce the packaging, or if they’re able to take back the packaging to recycle.

- It may be more beneficial to order in bulk or larger packs, as this will cut the volume of packaging per item.

- You could use reusable plastic boxes to place and protect materials in. These boxes can then be returned to the supplier.

- Use large sheets of plastic sheeting that arrived as wrapping for use on site as weather protection.

- For the plastic packaging that can’t be recycled, send it to a licensed Waste Management Contractor. They are best placed to decide their destination.

Not only does a reduction in packaging waste help the environment, it can also help your business too – financially. One contractor, Risby Homes, saved £13,000 on a 25-home development project, simply by reducing, reusing and recycling their plastic waste.

Construction companies can make simple changes that save money by reducing packaging waste, such as:

- Cutting costs by reusing packaging where possible.

- Time spent on handling waste, such as clearing and collecting waste, can be lengthy and pricey. Especially considering this cost can be easily cut by reducing packaging.

- Slashing the costs of skip hire and transport costs, as well as reducing the ever-increasing fees of landfill sites and tax.

The Innovative Ways Plastic is Being Recycled Across Construction

How can construction reduce and recycle the plastic in construction? Some companies in the industry are even creating decking from recycled plastic, which can save 1000 plastic bottles from landfill in a single metre of decking. That means in just a small sized decking 3,600 plastic bottles could be diverted from landfill.

But it doesn’t just stop there, Insulation Express has discovered the most innovative ways construction are reusing waste materials.

Nappy Roofing – More than half a million tonnes of waste is created in Britain from disposable nappies, and with each one taking around 500 years to decompose this is a concerning problem. But, instead of letting the waste decompose, you could be looking at roofing your house with them. A company have found a way to turn waste nappies into roof tiles, which could save 110,000 tonnes of CO2 emissions a year.

Plastic Roads – Roads are traditionally made from asphalt which uses stone and gravel to form the infrastructure. However, future roads could be made from used plastic – dubbed plasphalt. Amazingly, as well as a way of recycling plastic, this method of forming pavements is also stronger than asphalt and less expensive.

Plastic Concrete – Researchers from Bath University have found an ingenious way to save sand and reuse plastic waste. The scientists have discovered that 10% of the sand in concrete can be replaced with plastic waste. Concrete requires 30% of sand, which strips our beaches and riverbeds. Just replacing 10% of it can save over 800 million tonnes of sand.

What Does the Future Hold for Plastic in Construction?

Plastic still has a place in construction; it’s durable, waterproof and lasts long. Although plastic is polluting our environment, it doesn’t have to be the enemy. Indeed, there are ways for plastic to be part of the solution, such as recycling plastic into other building materials. In the future we may see a massive take up of alternatives to plastic in construction, some of these are already being developed and trialled. But for the average construction professional, you can reduce plastic use by talking to your supplier, educating your workforce and setting a good example to employees.