FLI Carlow are the premier total service provider of engineered structural solutions to the Water, Energy, Storm Attenuation and Bespoke markets. Our capacity to design not just the precast units, but the structure into which they integrate and the manufacturing tools used to make them has kept us at the forefront of innovation in our industry.

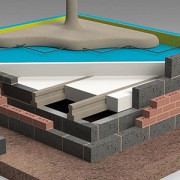

Semi-precast is the core of our business, a hybrid between traditional in-situ concrete and traditional precast. Although sometimes seen as an under-developed off-site manufactured solution, the semi-precast design philosophy brings enormous improvement to cost and construction efficiency.

The semi-precast approach aims to deliver solutions fully compliant with the operational design requirement. The ideal configuration is not adapted to prefabrication. Whereas we will identify cost and time saving opportunities during the design development phase, we can adapt to the most precise configurations for operational accuracy. In principle, any structure imagined in in-situ concrete can be delivered in semi-precast. Approving Authority confidence is engendered by implementing designs which cannot be disproved by failure to comply in any respect with the specified codes and standards, whether national, international or customer specific. We place wet concrete against hard concrete, the way it’s always been done. The difference is that some of the concrete was manufactured elsewhere and the location of joints and interfaces are unconventional. Regardless, the integrity of joints and interfaces remains uncompromised and verified by design.

The Benefit of Prefabrication

We complete the difficult parts of construction in our factory, under ideal conditions and under quality supervision. Features including pipe-fittings, nibs, corbels, launder-channels, formwork attachments and stability-footings (among others) are eliminated from the site works. Products are delivered to site on a just-in-time basis then taken from the delivery vehicle to their service position in one simple operation without fuss or temporary propping. Small crews achieve amazing productivity by following simple steps and using well designed components and delivery systems.

Tolerance

Precast concrete units can weight in excess of 20 tonnes. Under normal manufacturing tolerances, it could be very difficult to ensure the precision required to maintain accurate alignment and watertight fit. The in-situ joint provides a transition between elements which ensures a complete and perfect fit (in it’s liquid phase) and a completely ‘relaxed’ structure at introduction to service. We don’t stress pieces into alignment or position. The design assumptions are fully realised.

Waterproofing Integrity

At every interface a scabbled surface is prepared. In addition, a smooth dense slot is preserved for the application of hydrophilic strip. This provides ongoing self-healing capability in service. We use only one hydrophilic product; Denso Hydrotite. Hydrotite is resilient to inflation prior to encasement in concrete. It can compress against the surrounding concrete with a pressure of up to 3MPa on contact with water and has been approved by Tokyo Underground for design life up to 100 years. It is also DWI and Materials in Contact approved for potable water applications in the UK. That’s 100 years to first significant maintenance of the structure – no compromise. Sealants used at the mechanical interfaces of traditional precast concrete tanking structures rarely have a service life in excess of 20 years. These features are particularly relevant to storm attenuation, storage, treatment and basement applications,

Structural Continuity

Although relatively short, the in-situ joint is used to enable two-way bending of the structure. This capacity is not available using any other precast approach. Reinforcement lap lengths are designed on a bond-stress basis to ensure full capacity in smaller spaces. Even the interface between the in-situ concrete stitch and the precast unit is designed for the same crack-width control as the body of the structure. This ensures that all elements of the structure provide the minimum standard of waterproofing integrity and full compliance with concrete structures design standards.

By bending in both orthogonal directions, structures are thinner, lighter, economical, require less transport, less craneage and have a lower carbon cost.

Carbon

Our particular concrete mix design delivers very high early strength for efficient production, typically, 25 Newtons at 16 hours. This ensures maximum safety and maximum value by extracting products daily. We use very high concentrations of GGBS (66%) which in conjunction with other energy and carbon saving measures has reduced our carbon cost from 278kg/tonne of concrete manufactured to 182kg/tonne. To ensure the high early strengths despite the use of GGBS we use thermal activation. By adding mixing water at up to 80°C the disadvantage of slow strength development of GGBS is eliminated.

Sulphate Resistance

High levels of GGBS when used in conjunction with limestone cement and limestone powders (for self-compacting behaviour) produce a design chemical resistance class DC4. That’s sulphate resistant concrete at no additional cost.

Value

The precast unit is delivered to site with projecting reinforcement often from five of it’s six faces. All components are 3D modelled prior to manufacture and assembled in model-space prior to fabrication. This eliminates the risk of clashing reinforcement and disruption to programme. Projecting reinforcement leaves very few bars to be placed on site.

Typically the vertical in-situ stitches represent 30% of the volume of the perimeter and internal walls. While precast concrete products are relatively expensive (although value-adding), the concrete used in the joints is locally sourced readymix at approximately £40 per tonne.

The formwork required is very light. Shuttering ply facing with vertical stiffeners is locked against the structure using steel braces and MKK cone anchors. The advantage in this low cost approach is that the formwork is torsionally flexible adapting easily to the surfaces on which they bear. Smooth transitions and tight interfaces are achieved. Through-ties are completely eliminated. These are often a problematic feature of conventional in-situ works.

Length of Joints

The number and length of joints in our solutions are often questioned. Our industry sees joints as the most problematic elements of waterproof concrete construction – more joints, more risk. The rebuttal is that it’s not the number of joints you fear, but the distance between them. Traditional construction methods utilise joints at 6m – 10m centres. Thermal and drying shrinkage accumulate over these lengths and are concentrated at a single interface. The precast unit has long completed its shrinkage when placed on site therefore the shrinkage to be addressed is that occurring over only 500mm. In addition, each interface has the benefit of a factory prepared scabble, reinforcement continuity designed to the higher standards for crack-width control and a self-healing strip at each end. The semi-precast interface is subject to only between 5% and 10% of the movement occurring at conventional joint. As a result, it is significantly better preforming than conventional concrete in this respect.

Rate of Construction

Semi-precast structures are typically completed in 60% to 40% of the time taken to deliver conventional structures. This is where the value lies, both in terms of reduced preliminaries and hugely increased productivity. During the conventionally difficult construction of vertical and suspended works, equivalent productivity per person on site is ten times greater.

Leave a Reply

Want to join the discussion?Feel free to contribute!