Dave Newton of Brio looks at developments and trends in exterior and interior door openings

With such a high demand for internal and external bi-folding and straight sliding doors in both domestic and commercial settings many architects are continually challenging themselves to come up with designs that are getting ever closer to the ‘cutting edge’.

According to David Newton, General Manager at Brio UK, that means manufacturers of sliding and bi-folding door architectural hardware need to keep pace, if not outstrip, the architect’s need for creating innovative product that can transform anything they design on paper into reality.

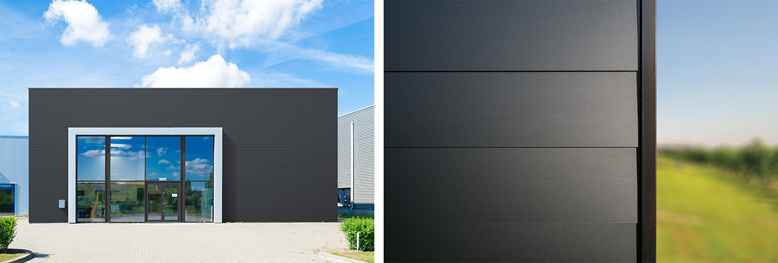

Newton explains: “At one end of the scale there is a call for glass doors with ceiling inset runners that that give the appearance of the door floating elegantly in the space – creating a physical yet ephemeral acoustic barrier – while at the other end there is demand for a rustic, even industrial, robustness that makes a feature out of fixings on barn-like partitions, where they actually become an integral part of the design. And, of course there is still a need for sliding and bi-folding doors of wood, aluminium and composite materials, with or without glass, that make the most of the available light while offering variety in how the space is used.”

Basically, the options open to architects when designing doors and windows are wood, steel/aluminium, composite and glass – or a combination of those. But what architectural hardware is best suited to the job of moving the finished product?

According to Newton this is where a good working partnership with a quality solution provider really pays off for architects. A leading architectural hardware manufacturer with a large range of fixings for all types of door creates a whole world of choice, and one that goes the extra mile for customers, takes on specification for them and is prepared to be flexible makes things a whole lot easier too.

Architects need a manufacturer partner which will ensure the correct architectural hardware is supplied. We work in partnership with the marketplace and are dedicated to producing bespoke, made to measure quality products.

He cites a project undertaken by a joinery firm commissioned to make sliding doors for a leisure centre according to the architect’s specifications and deliver the wood, facias and trim to site for the contractor’s joiners to assemble there. The area taken up by the sliding doors exceeded 13 metres and bought in 10 x 1in boards and laminated them together to make each 63mm door. They made their own oak laminate because, although there is ready laminated product, it is only 3-4ft in length, which was no good for that project. The doors were supplied to site with Brio Stainless Steel Timberoll sliding door gear teamed with Timberoll Brass tracks. This was the ideal combination for the area and the doors work beautifully, gliding effortlessly with just a fingertip push.

The creation of Zero Clearance Glass by Brio was in response to a need for recessed ceiling fittings for ‘floating’ glass doors and it’s not just top and bottom gear that needs to be innovative and fit for purpose. Locking mechanisms and hinges are all part of the complete package and they have to be top standard too. Brio never stops innovating. For example, the 286 Dual Point Lock for Weatherfold 4s with timber or aluminium panels has been developed as an optional for alternative to using flush bolts on panels. Aesthetically it’s better on the eye, as well as being easier to operate, as there is no bending down or reaching up to lock or unlocks the door which is the downside of flush bolts. This makes it very friendly with regards to disabled access.

At the end of the day, door hardware needs to be aesthetically pleasing, durable and reasonably priced. Architects and specifiers will always demand products that tick many boxes – visual appearance is important, as well as durability of the product but in the main they will be looking for a product that looks good, and, can also offer years of trouble-free use. This is true whatever the material they are made from.

Brio is a global company focused on bringing adventurous ideas to life, converting the conceptual thoughts of our customers into exciting reality. I sincerely believe the Brio range of quality, well designed product combined with expert technical resources makes us a world leader in design and quality.

For more details on the BRIO product range visit www.briouk.com