Despite dire predictions that mortality rates from overheating are expected to rise*, the Government has only just recognised the need to regulate in this area. Overheating, Approved Document O, is being introduced to the Building Regulations which will come into effect on the 15th June 2022 for new residential buildings in England.

Managing Director at Whitecode Consulting, Alex Hill, examines what this new regulation means for architects, if it goes far enough and if it is all just too little, too late.

Mitigating overheating in residential buildings is essential to protect the health and welfare or those who live in them. The new regulation aims to reduce the occurrence of high indoor temperatures in new residential buildings by limiting unwanted solar gains in the summer, whilst ensuring that there are adequate means of removing excess heat from the indoor environment when necessary. To comply with the new requirement, designers can use the simplified method or the dynamic thermal modelling method. Whichever route is selected, Whitecode Consulting has the experience and expertise to help clients navigate their chosen path.

At Whitecode Consulting we have a great deal of experience carrying out thermal assessments because for many years we have carried our CIBSE’s TM59 thermal assessments to predict overheating risk in buildings to comply with the London Plan. The new regulation however does apply limits to CIBSE’s thermal modelling method which has to be used when the simplified method of mitigating the impact of overheating can’t be used.

The simplified method can be used when the geographical level of risk has been established and the design of the building allows for cross-ventilation (openings on opposite facades). The new regulation sets standards under this simplified method to limit solar gain in homes, the standards go further when buildings are deemed to be in high-risk locations (for example parts of London and central Manchester). Standards are also set for the removal of excess heat. Multi-occupancy residential buildings would need each residential unit to be categorised separately for cross-ventilation purposes as well as any shared communal rooms or common spaces. This simplified method is not suitable for buildings with more than one residential unit that use a communal heating or hot water system with significant amounts of pipework and with a main distribution route through vertical risers.

Using the dynamic thermal modelling method will offer designers more design flexibility and I can see this being the preferred method even in areas considered at moderate risk. We are experiencing the perfect storm; newly constructed houses aim to increase thermal efficiency in the winter which means they may not be able to cope with extreme temperatures as a result of climate change that we could be experiencing in the future. This means that there is a huge risk of buildings overheating unless robust measures are taken immediately. The new regulation does not apply to work subject to a building notice, full plans application or initial notice submitted before 15th June 2022, provided the work for each building is started before 15th June 2023. Has the government missed a chance to protect people from the very real dangers of overheating right now?

Acceptable strategies to reduce overheating include: fixed shading devices like shutters and external blinds; glazing design solutions including size, orientation, and g-value; building design, for example the placement of balconies; and shading provided by adjacent permanent buildings, structures or landscaping. The use of Internal blinds and curtains though helpful in reducing solar gains will not be considered as complying with the new regulation.

Foliage and tree cover will also not be taken into account under the new regulation. I believe this might be a mistake because it would seem to exclude ‘living walls.’ Living walls or green walls of plants can provide a huge number of benefits, they not only reduce the temperature of a building’s walls, but they also support biodiversity and reduce air and noise pollution too. We should learn the lessons of our colleagues in warmer climates who are enjoying the benefits of living walls being fitted to new and existing buildings. This leads me to my next concern. That this regulation is for new residential buildings only, many of the strategies to reduce solar gain in new builds can be retrospectively fitted into older repurposed buildings. If the government really believed in tackling overheating in residential buildings, they could have gone further with the regulations to encompass more living spaces.

To remove excess heat the following means are considered sufficient under Part O: opening windows, ventilation louvres in external walls, and a mechanical ventilation system. A building’s overheating mitigation strategy needs to consider external noise, pollution, security and ensure that occupants of a building are protected from falling and entrapment. If external noise is an issue for example, it is unlikely that windows can be opened, in which case dynamic thermal modelling should be used. As with all new regulations they don’t stand alone, they interact with other parts of Building Regulations. For example, Part O gives guidance on window openings for removing excess heat, Part B gives guidance on the size of escape windows. Extra glazing needed to comply with Part B could impact the risk of overheating in the building.

All practical passive means of removing excess heat will have to be used first before mechanical cooling can be adopted. This caveat is welcome in this new regulation, though I fear as we see more extreme temperatures spikes in the future, we will also see a huge rise in the use of mechanical cooling systems, increasing the amount of energy consumed by buildings which is the opposite of what we are working towards.

I believe that the new regulation is much needed, but it could go further to really tackle the growing issue of overheating in buildings. As an industry, we need to foster innovation and go beyond the minimum standards, however, this new standard should initiate this much needed change.

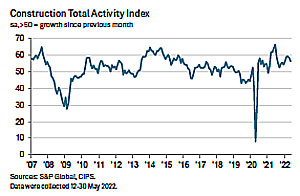

May PMI® data signalled another growth slowdown in the construction sector amid a considerable loss of momentum for the residential category. The latest rise in housing activity was the weakest since the recovery began two years ago. Survey respondents suggested the subdued consumer confidence and worries about the economic outlook had constrained demand.

May PMI® data signalled another growth slowdown in the construction sector amid a considerable loss of momentum for the residential category. The latest rise in housing activity was the weakest since the recovery began two years ago. Survey respondents suggested the subdued consumer confidence and worries about the economic outlook had constrained demand.