Kingspan Kooltherm Pipe Insulation and The Kingspan KoolDuct System have been fitted as part of a new training school developed by Nuenta and Ecoforest, supporting installers to make the transition to new, low carbon heating approaches.

The state-of-the-art Ecoforest UK training school in Cannock was officially opened at the start of July. The facility is one of eight around the world and offers a 2-day training course where attendees have the opportunity to get hands-on with a range of technologies including inverter driven ground and air source heat pumps. The centre also provides online courses discussing a range of topics including the environmental and economic benefits of the low-carbon approaches.

In addition to showcasing the latest developments in these technologies, the training courses also emphasise the importance of maximising system efficiency to deliver truly low carbon buildings. This has been put into practice for the facility’s specification, which features leading passive solutions including Kingspan Kooltherm Pipe Insulation and The Kingspan KoolDuct System.

Craig Baker, Technical Director at Nuenta commented:

“We are delighted to be able to open the facility, helping to address the urgent need for installers trained in the use of low carbon technologies. The Kingspan Technical Insulation products installed in the centre help to showcase best practice and are also helping to reduce operational costs for the school.”

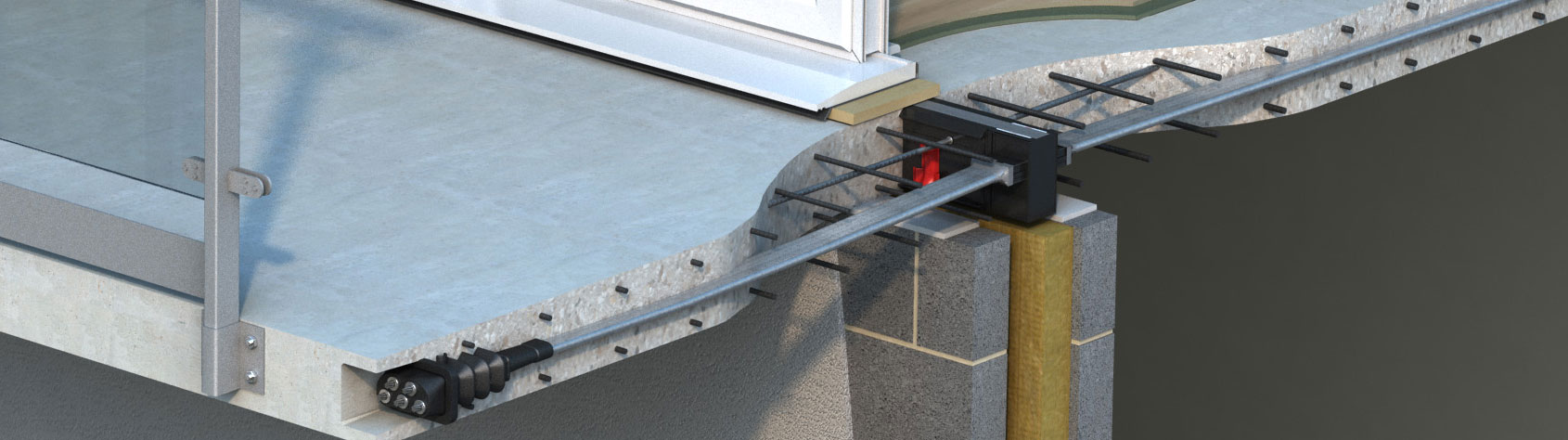

The Kingspan KoolDuct System is fabricated from pre-insulated panels and offers a number of benefits over conventional lagged sheet metal alternatives. It is formed from lightweight, insulation panels which can be quickly and easily fabricated into ductwork and installed in long-runs. Ductwork fabricated from the system can also achieve air leakage rates which are a fraction of those of typical rectangular sheet metal ductwork. This highly airtight design, in combination with the premium performance insulation core within the KoolDuct panels, is expected to minimise the energy demand of mechanical ventilation systems within the centre.

Kingspan Kooltherm Pipe Insulation was fitted on pipework across the facility. The product provides one of the most thermally efficient pipework insulation solutions, helping to ensure the desired level of thermal performance could be achieve with a minimal thickness of insulation. The product also holds Eurofins Indoor Air Comfort Gold certification, recognising it as having best-in-class low VOC emissions.

To further raise system performance, Kooltherm Insulated Pipe Support Inserts were also installed on the project. These help to effectively isolate the system pipework, limiting thermal bridges at the support, which can account for a significant amount of heat loss from heating and domestic hot water pipework. The inserts also help to ensure the continuous vapour barrier is carried to the support systems.

Both Kooltherm Pipe Insulation and The Kingspan KoolDuct System are available with free BIM product objects which can be freely downloaded from bimstore.co.uk. Additionally, both products are supported with Environmental Product Declarations (EPDs), which are available to download from the Kingspan Technical Insulation website, providing in-depth lifecycle information about the products.

The Centre also features a range of technologies from Zehnder.

Chris Kemp, Business Development Manager at Zehnder Group, added:

“The creation of the new Ecoforest training facility in Cannock has been a fantastic joint project to work on and we’re all delighted with the results. Not only has it provided new installers the opportunity to get trained on the ComfoAir Post, it showcases the benefits of the products.”

“We all know that efficient and environmentally friendly heating and ventilation is vital for the future of the sector. Government has very ambitious targets of achieving some 600,000 new heat pumps to be installed across the UK every year. We are currently suffering from a massive skills shortage in our sector and this goes a small way in starting to address that need.”

For more information:

Tel: +44 (0) 1457 890 400

Email: info@kingspaninsulation.co.uk

WEBSITE

Brian Mack, Technical Business Development Manager at EJOT UK said: “With the widespread specification of LIEBIG Superplus BLS anchors in safety critical applications throughout the UK, we wanted to take early action to achieve UKTA certification and give specifiers complete confidence when designing concrete applications.

Brian Mack, Technical Business Development Manager at EJOT UK said: “With the widespread specification of LIEBIG Superplus BLS anchors in safety critical applications throughout the UK, we wanted to take early action to achieve UKTA certification and give specifiers complete confidence when designing concrete applications.