With the introduction of HeartFelt® Origami, architects and interior designers can add a highly exclusive ceiling finish to their buildings. This new Hunter Douglas Architectural felt ceiling system not only has a unique aesthetic appearance, it also provides high acoustic performance. The combination of material – felt, in five shades of grey, and shape – origami folded panels – gives any room a distinctive look.

HeartFelt® Origami is the latest line to be launched in the already popular felt ceiling and wall system. With this new design, Hunter Douglas Architectural launches a ceiling system that is based on ancient origami techniques. This method of folding gives the felt panels additional rigidity and superior acoustic properties, as well as a particularly attractive finish and high degree of acoustics.

“When developing our new design, we studied the oriental folding technique in detail. Origami is, in fact, a very practical method of making materials rigid without the need to add other materials or products. As a result, this system can play a key part in our desire for and pursuit of circular and sustainable construction. At the same time, the final shape, a playful plane of triangles, achieves strong sound dampening results,” says Marijn Verlinde, Technical Product Manager at Hunter Douglas Architectural.

For architects and interior designers in particular, the new ceiling system provides added value in several ways. Aesthetically, HeartFelt® Origami offers an exclusive and highly creative ceiling finish. Because there are five different sizes, the designer has the freedom to choose a shape, or combination of shapes, that best suits a particular space, while striking tones or single colour designs can be created by selecting from the five shades of grey, ranging from white to black. In time, this colour palette will be expanded.

Extensive testing has shown the panels to achieve a sound absorption value of αW 0.8, ensuring reverberation and noise in busy office landscapes, public buildings or other premises are greatly reduced.

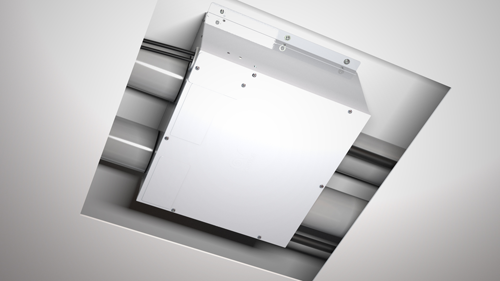

The ceiling system’s simple and quick installation is another benefit. The basic material consists of flat felt panels and the final shape is created during installation via the folding lines and incisions. During installation, the profiles are first attached to a rail system on the ceiling and the panels are then attached to the profile by a wedging system. This way, the origami patterns on the ceiling create an attractive finish, which, with the right lighting, results in a stunning interaction of light and shadow. HeartFelt® Origami can be installed as a room-filling ceiling system or as a stand-alone solution.

For more information on HeartFelt® Origami, please visit our website:

installation, including settings for fan speed, relative humidity, time interval of sleep mode and activation temperatures of free-cooling mode. Maintenance is easy too, with magnetic covers offering access to the G3 filters and a remote control panel display signalling when cleaning and maintenance is necessary.

installation, including settings for fan speed, relative humidity, time interval of sleep mode and activation temperatures of free-cooling mode. Maintenance is easy too, with magnetic covers offering access to the G3 filters and a remote control panel display signalling when cleaning and maintenance is necessary. All bathrooms and shower rooms in the scheme have been fitted with Altro Aquarius safety flooring, in the colours Swan, Cygnet, or Tern. This specialist flooring solution is designed for combined wet and dry, shoe and barefoot areas, so is ideal for bathrooms, showers, saunas and spas.

All bathrooms and shower rooms in the scheme have been fitted with Altro Aquarius safety flooring, in the colours Swan, Cygnet, or Tern. This specialist flooring solution is designed for combined wet and dry, shoe and barefoot areas, so is ideal for bathrooms, showers, saunas and spas.