Mr Monk’s approach in Cornwall is exactly what Mr Gove wants to see from local authorities

Cornwall Council’s portfolio holder for housing and planning, Olly Monk wants 10,000 homes built to battle Cornwalls acute housing shortage. Monk says:

“I don’t care if I am not re-elected, I just want to make sure there are homes for future generations here.”

Langarth Garden Village near Truro is an ambitious new town development – which is being built by Cornwall Council’s civil engineering arm, Cormac – is an attempt to address the area’s acute housing shortage while also building new infrastructure.

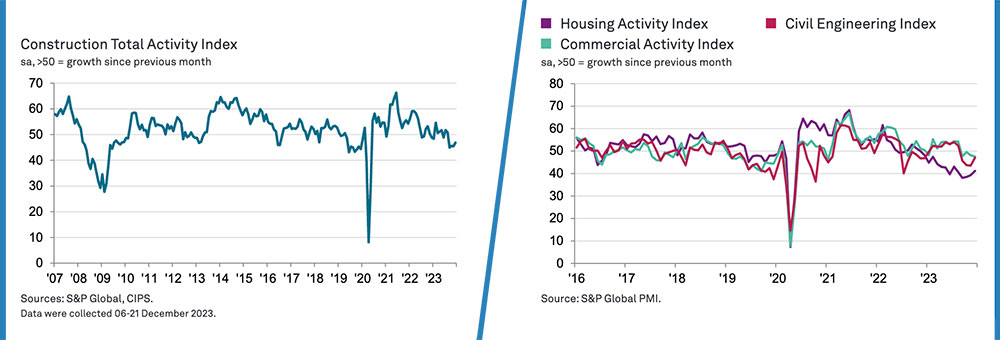

Data show that UK construction activity contracted for the third month in a row in December due to a slump in housebuilding. Meanwhile, there are over a million households on social housing waiting lists across England. And, in 2023, the number of homeless people sleeping in temporary accommodation hit an all-time high of 104,510 households, including 131,370 dependent children.

Cornwall has been particularly hard hit in recent years in part due to a rise in the number second holiday homes and holiday lets. This has led to a rise in homelessness and a crisis whereby low-income households – including key workers – increasingly can’t afford to live in the area.

Nestled between two hills, Langarth is exactly the sort of future-facing new town that both Leveling Up and Housing Secretary Michael Gove and Labour leader Sir Keir Starmer have been calling for as both of Labour and the Conservatives make bids to be the party of “builders, not blockers”.

Planning policy is something of a political oxymoron. It manages to be at once incredibly technical, humdrum, and, yet, controversial to the extent that it can trigger backbench rebellions in Westminster and social media wars between rival factions.

Those factions are known as the pro-building Yimbys – Yes In My Back Yard – and anti-development Nimbys – Not In My Back Yard. They can regularly be found warring on X (formerly known as Twitter) or leafleting at political conferences.

Langarth will be made up of approximately 3,550 new homes available only to local people. To make sure these homes can be supported, the development also includes a new 8km road, a cycle highway, two new schools, a rugby pitch, a football pitch and an environmentally friendly geothermal heating network.

But not everyone wanted Cornwall Council’s vital new housing initiative to get planning approval.

Across England, private rents are soaring above what people can afford, social housing waiting lists are ballooning and new homes are simply not being built quickly enough by private developers who are often accused of “land banking” – this is where they sit on land which is earmarked for development but wait for its value to appreciate before building on it.

Sometimes it is the builders who are, in fact, the blockers.

To make Langarth a reality, Mr Monk – who was first elected in 2017 – had to take on private developers who owned some of the land it is now being built on. He exercised his right to use Compulsory Purchase Orders (CPOs) to buy land they were sitting on but not building on back into public ownership. But, even then, landowners submitted planning objections citing a “conflict of interest”.

“I believe that councils shouldn’t be afraid to use [CPOs] when it’s for the greater good,”

“Everyone has their reasons for either supporting or objecting to development, but I don’t think councils should be afraid to push forward a scheme like this – we have to ensure that there is housing for local people.”

“We’ve got the resolve and determination to deliver houses,” he added. “If you just listened to every single objection, you’d never build a house anywhere.”

Mr Monk is, unusually for a politician, unbothered about being popular. He cares more, he says, about knowing he did his bit to shore up the future of Cornwall.

He advocates for local authorities being “strategic” and “thinking about what they need to be doing in the next 10, 20 or 30 years”. That, he said includes “making plans for garden villages and formulating a strategy to accumulate land and deliver”.

With no forward planning, Mr Monk says “balance in the housing will never materialise and things will just become more and more unfair”.

Mr Monk’s biggest fear is that housing will become “ever more out of reach” of “exactly the type of people you need living in communities” – that is key workers and young families; people on low and middle incomes.

In many ways, Mr Monk’s approach in Cornwall is exactly what Mr Gove wants to see from local authorities. While launching his long-awaited planning reform which will be delivered in a newly drafted National Planning Policy Framework, Mr Gove named and shamed 20 local authorities who are not delivering enough housing and seven who, he said, do not even have local plans.

However, the truth is that Mr Gove’s own plans to reform planning – which originally included forcing local councils to comply with mandatory housebuilding targets in a bid to get urgently homes needs under construction – had to be watered down at the end of 2022 due to a rebellion from 60 Conservative Nimby MPs who had concerns about building at scale in areas of natural beauty.

Mr Gove’s new plans now include investing in planning, but not bringing back housing targets.

Labour, on the other hand, is proposing to strengthen Section 106 – the mechanism through which developers are compelled to deliver social homes as part of new builds.

When Liz Truss decided to abandon the Conservatives’ “Stalinist” housebuilding target of 300,000 new homes a year in 2022, investors were spooked. Housing targets, like the local plans Mr Gove is demanding to see, show investors – on whom developers rely for funding – that housebuilding is being taken seriously and that there will be demand.

One of the councils that Mr Gove chose to criticise was the Labour-run Wandsworth Council in London. According to the Housing Secretary, Wandsworth is “exacerbating” housing shortages by putting pressure on developers to deliver affordable housing instead of allowing them to focus on getting new homes for private sale built.

Councillor Aydin Dikerdem, 32, is Wandsworth’s cabinet member for housing. He was elected in 2016.

Speaking at Battersea Arts Centre, he told said that

“local government needs more powers and more grants to ensure developers are delivering [affordable social housing], not further deregulation”.

In 2010, the Conservatives cut funding for affordable housing by 60 per cent as part of the austerity drive to cut the deficit between public funds and spending. Today there is an £11.5bn Affordable Homes Programme but it has not increased in line with inflation.

Mr Dikerdem has, like his Conservative counterpart in Cornwall, taken a hard line with developers in Wandsworth. He has overseen the redrawing of the area’s local plan (via something known as Regulation 18) and ensured that more truly affordable homes can be delivered via a new strategy called Homes for Wandsworth – which will see 1,000 council homes built on council-owned land.

Labour councillor Aydin Dikerdem, second left, has, like his Conservative counterpart in Cornwall Olly Monk, taken a hard line with developers in Wandsworth

Wandsworth currently has a social housing waiting list of nearly 10,000 households.

“We inherited a local plan from the previous Conservative administration we were unhappy with,” Mr Dikerdem said.

Historically in Wandsworth, property developers have only had to provide 35 per cent affordable homes when they built in the borough.

“We want an affordable housing/housing for private sale split which favours social rent at 70 per cent and intermediate products like shared ownership at 30 per cent,” Mr Dikerdem added. “That’s the maximum allowed under the Greater London Authority’s London plan and the most progressive a local council can be.”

And, instead of having local politicians be wined and dined by developers and their PR representatives, Mr Dikerdem invited them all to meet in Wandsworth’s town hall for “sandwiches and tap water”.

“The thing that developers want is stability,” Mr Dikerdem said. “They want to know where you stand and that you’re going to be consistent. So, it was really important for us to set very clear lines about what it is that we want.”

Mr Dikerdem says his team aim to deliver that stability because it will get homes built.

“Developers came to sandwiches and tap water,” he said. “It was an incredibly productive meeting. And they got excited about investing. The bar we’ve set here is not about speculative profit extraction, it’s about delivering the homes that people actually need.”

For Mr Dikerdem, it’s not just about building homes for private sale which can, and often are, snapped up by investors in London. It’s about building homes that are genuinely affordable for local people, which will bring down social housing waiting lists and get people out of emergency temporary accommodation.

“I think political leadership needs to be really tough on planning and to not be scared to push plans at the review stage,” Mr Dikerdem concluded. “The value of a newly built social home in London is worth fighting for. If you can get 10 more, 20 more, 30 more. It’s really worth it.”

Mr Dikerdem rejects Mr Gove’s implication that local governments like his who are trying to “negotiate essential social housing” with developers are the reason for low housebuilding figures.

Mr Monk is equally critical of the Conservative governments of the last 13 years.

“I don’t think local councils have enough power to build,” he said. “We want to build homes in Cornwall but trying to get that through planning is [too difficult].”

Mr Monk cites the example of giving telecommunications companies permitted development rights to put up 5G masts –

“if they did something like that for housing, you’d see a much bigger increase [in the volume] of affordable housing rolled out across the country”.

“I am disappointed with all governments, not just the current Government. They have failed to make really meaningful changes to the planning rules to allow the delivery of homes because of this protectionist attitude that people have.”

The Department for Levelling Up, Housing and Communities spokesperson said: “As the Housing Secretary has recently made clear, we must build more homes, but they need to be in the right places where people want to live. We recently laid out an ambitious long-term plan for housing and are on track to deliver one million homes this Parliament.

“We are clear that the way to deliver housing is through up-to-date local plans. The new National Planning Policy Framework increases the incentives for authorities to get local plans in place. There is now no excuse for any local authority not to have a plan in place, leaving communities without the homes they need.”

Source: iNews

and restoring old cottages, to working on new-build properties and erecting garden rooms for customers. In fact, I created an outdoor kitchen this summer for one client, though the work I did on an old stone-built property at Blockley – near Chipping Camden – pitching a new cut roof and creating new bedroom spaces, is more typical.

and restoring old cottages, to working on new-build properties and erecting garden rooms for customers. In fact, I created an outdoor kitchen this summer for one client, though the work I did on an old stone-built property at Blockley – near Chipping Camden – pitching a new cut roof and creating new bedroom spaces, is more typical.