As the UK moves towards a general election both the opposition party and current UK government are viewing energy costs as a weapon that can be used to attract electoral ballots. Both parties are reviewing their approach to truncating domestic and commercial energy costs.

The current opposition party has made public proposals to reduce electrical costs by 23% to moderate UK customer energy costs. Rinnai has produced modelling and a set of calculations that are based on an accommodation block and feature four separate appliances in a heating hot water delivery system as below -:

R290 Commercial heat pump System = 6x 50kW R290 HPs + 6x 800L HP Buffers.

R290 Commercial heat pump system + Electric storage water heater = 4x 95kW iMAX HPs + 2x 800L HP Buffers + 2x 800L E-cylinders electric water heaters e/w 60kW Immersions.

Heat Pump + gas fired continuous flow water heater System = 4x 95kW iMAX + 2x 800L HP Buffers + 4x N1600 continuous flow water heaters + 2x 800L cylinders.

Gas-fired continuous flow waters = 8x N1600 continuous flow water heaters + 2x 1000L cylinders.

Following is a set of calculations based on the proposed 23% reduction in electrical costs the opposition party suggested as future policy using the above systems and appliances.

This analysis was carried out to understand how the operating cost of each system differs when using forecasted electricity costs, which suggest a reduction of 23% in national grid consumed electricity, compared to the current government forecasted national grid figures.

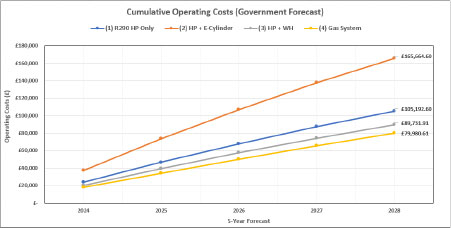

The below graph represents the current governments costs when used in an accommodation block application.

please note that HP equates to Heat Pump and WH translates as Water Heater (system)

A Rinnai R290 heat pump will cost £105,192.60; a heat pump and electric cylinder will cost £165, 664.60; a heat pump and water heater system will cost £89,731.90 whilst a natural gas system will produce costs of £79, 980. 61. All costs are measured over a 5-year period.

Below is another graph that represents the costs related to Rinnai products considering the 23% reduction in electric costs the opposition party are forecasting. A Rinnai R290 heat pump will cost £80,998.30; a heat pump and electric cylinder will charge customers £127,561.74; a heat pump and water heater will cost UK customers £76,291.29, whilst a natural gas system will cost £79,980.61. Again, all costs are also based on 5-year period.

Under the current opposition party proposals to reduce electricity costs by 23% a clear beneficial increase is denoted in customer fiscal outlay over a 5-year period. In both graphs the costs relating to the natural gas system stay static and can therefore be overlooked.

Costs of operating a R290 heat pump over 5 years is presently £105,192.60 and under current opposition plans to reduce electrical costs by 23% will be £80,998.30.

A heat pump and electrical cylinder over 5 years presently costs UK customers £165, 664.60. Under opposition plans to offer reductions in electrical costs the same product will cost £127,561.74.

Whilst a heat pump and water heater using the same metric as above currently costs £89,731.90. After reducing electrical costs by 23% the exact same product will require £76,291.29 over a 5-year period.

Clear reductions over a 5-year period are clear when observing heat pump and hybrid systems. Widespread electrification is a main objective by UK policy makers who aim to impose the cheapest electricity costs on UK households by 2035. Investing in a domestic or commercial application electric hybrid heating and hot water system could potentially result in huge reductions of operational costs.

One strong conclusion to be drawn from these figures is that all sites, consultants, contractors and end users should consider all factors before making a commitment to a system or appliances arrangement.

Contractors, consultants and installers who recognize the complexity of the current energy market should form partnerships with those organizations which have arranged their entire product offering to meet and exceed current and future energy policy.

CLICK HERE

To take advantage of Rinnai services for calculating capital expenditure, operational expenditure and carbon

Alternatively contact us today

0300 373 0660

RINNAI’S H3 DECARBONISATION OFFERS PATHWAYS & CUSTOMER COST REDUCTIONS

FOR COMMERCIAL, DOMESTIC AND OFF-GRID HEATING & HOT WATER DELIVERY

Rinnai’s H3 range of decarbonising products include hydrogen / BioLPG ready technology, hybrid systems, and a wide range of LOW GWP heat pumps and solar thermal. Also, within Rinnai’s H3 range is Infinity hydrogen blend ready and BioLPG ready continuous flow water heaters which are stacked with a multitude of features that ensure long life, robust & durable use, customer satisfaction and product efficiency.

Rinnai’s range of decarbonising products – H1/H2/H3 – consists of heat pump, solar, hydrogen in any configuration, hybrid formats for either residential or commercial applications. Rinnai’s H3 range of products offer contractors, consultants and end users a range of efficient, robust and affordable decarbonising appliances which create practical, economic and technically feasible solutions. The range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters.

Rinnai H1 continuous water heaters and boilers offer practical and economic decarbonization delivered through technological innovation in hydrogen and renewable liquid gas ready technology.

Rinnai’s H1 option is centred on hydrogen, as it is anticipated that clean hydrogen fuels will become internationally energy market-relevant in the future; Rinnai water heaters are hydrogen 20% blends ready and include the world’s first 100% hydrogen-ready hot water heating technology.

Rinnai H2 – Decarbonization simplified with renewable gas-ready units, Solar Thermal and Heat Pump Hybrids. Rinnai H2 is designed to introduce a practical and low-cost option which may suit specific sites and enable multiple decarbonisation pathways with the addition of high performance.

Rinnai H3 – Low-GWP heat pump technology made easy – Rinnai heat pumps are available for domestic and commercial usage with an extensive range of 4 – 115kW appliances.

Rinnai’s H3 heat pumps utilise R32 refrigerant and have favourable COP and SCOP.

Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

Rinnai’s commercial and domestic continuous flow water heaters offer a limitless supply of instantaneous temperature controlled hot water and all units are designed to align with present and future energy sources. Rinnai condensing water heaters accept either existing fuel or hydrogen gas blends. Rinnai units are also suited for off-grid customers who require LPG and BioLPG or DME.

Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours. Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question. Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s. More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

Visit www.rinnai-uk.co.uk

for more information on the RINNAI product range

Or email engineer@rinaiuk.com

Suitable for both renovation and new build projects, including locations with substantial and continuous hot water demands such as hotels and sports facilities, the Dorchester DR-SG meets all of the latest Building Regulations and offers significantly improved efficiency and performance when replacing a non-condensing water heater.

Suitable for both renovation and new build projects, including locations with substantial and continuous hot water demands such as hotels and sports facilities, the Dorchester DR-SG meets all of the latest Building Regulations and offers significantly improved efficiency and performance when replacing a non-condensing water heater.