Rinnai’s Chris Goggin explores how wider electrification of the UK domestic & commercial energy mix could influence decarbonisation efforts and customer choices of heating and hot water appliances.

Will Britain’s national electrical grid hold the capability of handling extra demand?

As part of the recent “Powering Up Britain” Govt document, wider electrification was specified as a key strategic aim in decarbonising the UK. Future domestic & commercial & industrial energy will be provided through several ways, one method of decarbonisation will focus on producing sustainably sourced and cheap electricity for UK customers.

There is a series of logical steps if NetZero is to be achieved by 2050. If the UK is going to proceed with decarbonisation through electrification, then providing the electricity for the mass use of electric vehicles will be key. To power an Electric Vehicle (EV) requires the widespread availability of charging points across the UK. There are over 33 million vehicles on the UK’s roads, the majority of which will require electricity.

Can current National Grid capacity cope with increase of electric vehicles AND the demand surge for domestic, commercial and industrial usage facilitated through wider UK electrification?

A BBC article published just recently has revealed that clean energy projects are being put on hold due to a lack of electrical grid capacity. Some renewable energy companies believe this lack of electrical grid capacity could potentially negate the progress of UK NetZero targets.

It has been estimated that the UK requires five times more solar power and four times as much wind generation than what is being presently manufactured. All of which will need to be connected to the national grid. The BBC report estimated that £200 billion of clean energy projects are waiting to be connected with 40% of these projects facing at least a year of further procrastinating.

UK decarbonisation aims are centred on the dispersal of clean and cheap electricity. However, relying on renewables in the short term to completely satisfy national energy supplies is not risk adverse. Renewable power yield relies on weather conditions that seasonally fluctuate.

Although possible, there are still theoretic and technical challenges that require addressing before the UK electric grid can be considered capable of handling both wider national electrification and the inclusion of EV’s on UK roads.

Electricity is generated through various renewable and non-renewable practises such as wind, solar, tidal, nuclear and natural gas. Although UK energy policy makers are keen on reducing and eventually phasing out fossil fuel usage altogether, natural gas has been recognized as a key decarbonising transitional fuel source, as it is used in times of low wind yield to produce electricity (wind being the second highest contributor to UK electrical generation at 25%).

UK policy makers have identified cheap and sustainable electricity as a main contributor to national decarbonisation efforts. As a result, the UK’s electrical capacity grid will have to be expanded. ‘Powering up Britain’ also states that energy independence can be achieved through potentially doubling Britain’s electrical capacity by 2030 whilst ensuring cost effective electrified power.

To provide continuity to UK home market energy supplies, a baseload of power is dispersed to communities throughout the UK. A baseload of power ensures that the minimum requirement of national demand is constantly met. Baseload energy demands are satisfied via energy sources that are cost effective and readily available, such as natural gas.

Dispatchable power are separate sources of energy that are utilized in times of peak demand. Throughout the calendar year the UK power grid will experience times of pressure where it is a necessity to incorporate additional energy to cope with demand and output.

Current capacity of the UK electrical grid stands at 334.2 TWh (terawatt-hour: a unit of energy equal to one trillion watts for one hour). It is estimated that with the inclusion of electric vehicles will create an additional 100TWh demand increase. That, in rounded terms, means an increase of about one third of current levels.

The UK electrical grid is designed to coincide with seasonal and daily peak times of demand. For example, in a seasonal context the demand for electricity is far higher in January then it is in July. Daily electrical demand rhythms are similar – evening demand is far higher than in mid to early afternoon.

Developments in technology, energy efficiency and inclusion of renewables mean that the UK electric grid needs to be positioned to deal with further output demand created by the anticipated but not guaranteed widespread EV adoption across the UK.

Work will also continue to develop V2G (vehicle-to-grid) technology that allows electric car owners to send excess un-used electricity back to the grid when demand is high further creating grid flexibility.

Inter-continental grid connections to countries such as France, the Netherlands, Ireland, Belgium and Norway are connected to the UK through sub-sea cables. This means the UK grid can access power from other nations in times of high demand and system stress, as well as import and export at financially beneficial rates.

The recent “Powering Up Britain” paper stated the UK government’s aim to accelerate delivery of strategic transmission upgrades by at least three years with the specific aim of reducing delivery time in half to UK customers. The Electricity Networks Commissioner will be advising the UK government on how to accelerate grid delivery and will present recommendations to ministers in June.

Rinnai understands the complexity of UK decarbonisation efforts and we are committed to informing UK customers on the detail and impact of current and future energy policy as well as shifts in the energy landscape that could affect customer cost.

RINNAI’S H3 DECARBONISATION OFFERS PATHWAYS & CUSTOMER COST REDUCTIONS FOR

COMMERCIAL, DOMESTIC AND OFF-GRID HEATING & HOT WATER DELIVERY

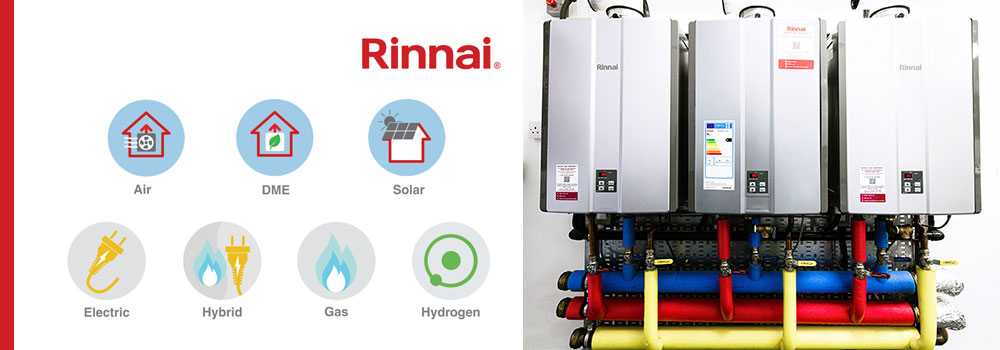

Rinnai’s H3 range of decarbonising products include hydrogen / BioLPG ready technology, hybrid systems, and a wide range of LOW GWP heat pumps and solar thermal. Also, within Rinnai’s H3 range is Infinity hydrogen blend ready and BioLPG ready continuous flow water heaters which are stacked with a multitude of features that ensure long life, robust & durable use, customer satisfaction and product efficiency.

Rinnai’s range of decarbonising products – H1/H2/H3 – consists of heat pump, solar, hydrogen in any configuration, hybrid formats for either residential or commercial applications. Rinnai’s H3 range of products offer contractors, consultants and end users a range of efficient, robust and affordable decarbonising appliances which create practical, economic and technically feasible solutions. The range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, rDME solar thermal, low GWP heat pumps and electric water heaters.

Rinnai H1 continuous water heaters and boilers offer practical and economic decarbonization delivered through technological innovation in hydrogen and renewable liquid gas ready technology.

Rinnai’s H1 option is centred on hydrogen, as it is anticipated that clean hydrogen fuels will become internationally energy market-relevant in the future; Rinnai water heaters are hydrogen 20% blends ready and include the world’s first 100% hydrogen-ready hot water heating technology.

Rinnai H2 – Decarbonization simplified with renewable gas-ready units, Solar Thermal and Heat Pump Hybrids. Rinnai H2 is designed to introduce a practical and low-cost option which may suit specific sites and enable multiple decarbonisation pathways with the addition of high performance.

Rinnai H3 – Low-GWP heat pump technology made easy – Rinnai heat pumps are available for domestic and commercial usage with an extensive range of 4 – 115kW appliances.

Rinnai’s H3 heat pumps utilise R32 refrigerant and have favourable COP and SCOP.

Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

Rinnai’s commercial and domestic continuous flow water heaters offer a limitless supply of instantaneous temperature controlled hot water and all units are designed to align with present and future energy sources. Rinnai condensing water heaters accept either existing fuel or hydrogen gas blends. Rinnai units are also suited for off-grid customers who require LPG and BioLPG or rDME.

Rinnai products are i2HY20 certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours. Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question. Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s. More information can be found on Rinnai’s website and its “Help Me Choose” webpage.