Portakabin, a leader in modular construction solutions, is proud to announce the upcoming completion of the Dairy Nexus, a state-of-the-art research and innovation facility at Scotland’s Rural College (SRUC) Barony Campus near Dumfries.

Set to open in November 2024, this ground-breaking facility was built by Portakabin in collaboration with SRUC, as part of the Borderlands Inclusive Growth Deal, to drive advances in dairy sustainability and productivity for Scotland and the UK.

The Dairy Nexus represents a multi-million-pound investment, bolstered by funding from both the UK and Scottish Governments. Located at the heart of one of Scotland’s most active dairy-producing regions, the facility will serve as a hub for collaborative research among scientists, farmers, advisors, and technology providers, pushing forward the frontiers of dairy innovation.

The Dairy Nexus features cutting-edge laboratories, collaborative meeting spaces and technical equipment designed to enhance the sector’s ability to conduct pioneering research. The facility will explore sustainable dairy practise ranging from optimising dairy nutrition to enhance milk quality, to genetic research that can reduce cows’ methane emissions. This work aligns with the goals of the UK’s Net Zero initiative and Scotland’s Green Industrial Strategy, making a significant step toward decarbonising the dairy industry.

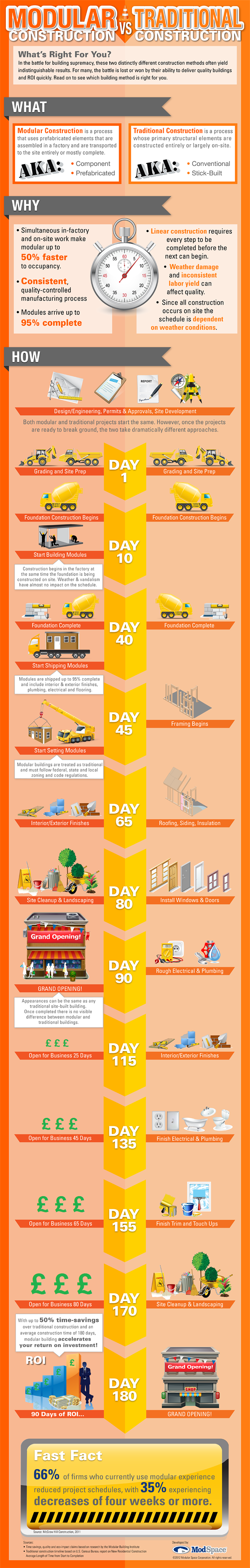

Portakabin is renowned for its advanced modular construction capabilities, specialising in high-quality, flexible buildings that meet technical and environmental standards. The design of Portakabin modular buildings allows for rapid, cost-effective construction without compromising on durability or customisation, making them an ideal choice for projects requiring specialised research facilities.

“At Portakabin, we are committed to providing adaptable, high-performance facilities that help solve real-world challenges. The Dairy Nexus project embodies our values, utilising modular construction to bring a vital research and innovation centre for life swiftly and sustainably” James Pearson, Divisional MD at Portakabin. “This facility will enable dairy sector leaders and researchers to work towards transformative improvements in dairy productivity and environmental impact.”

Professor Wayne Powell, Principal and Chief Executive of SRUC, said:

“We are delighted to see the Dairy Nexus moving a step closer to opening on our Barony campus.

“It encapsulates our mission to drive imaginative new ways of working between business, government, communities, and universities to support a green recovery in remote and rural parts of Scotland.

“It will also support the work of the Digital Dairy Chain at Barony, which is focused on developing digital connectivity, stimulating research and new product development, supporting business growth and attracting talent and skills, across the region.”

The Portakabin team will be thrilled to handover this project towards the end of 2024.

CLICK HERE to see more projects from Portakabin