A well-insulated house or office will protect your health, comfort and lifestyle but how many of us know and understand how to achieve this?

Ecomerchant and Steico UK have joined forces to launch a protection campaign. It aims to champion the benefits of using natural insulation products.

How we select insulation needs to be about having a real choice and for specifiers to be equipped with the right knowledge to compare materials on a like-for-like basis.

To design a well-insulated building, you need to make informed decisions throughout all phases of a construction project to ensure your building performs as you envisage.

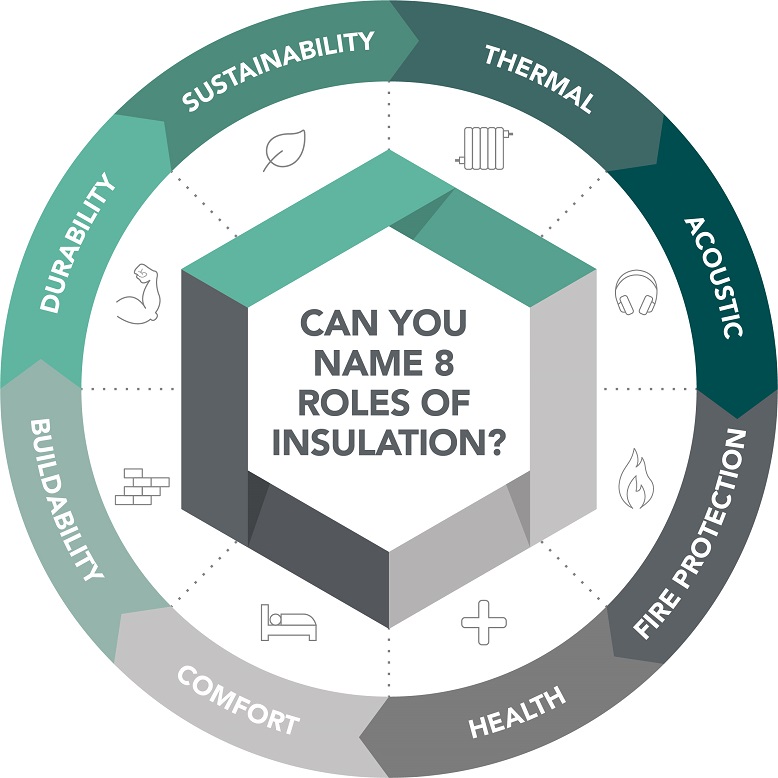

However, selecting the right insulation is about more than just reaching building regulation compliance or ‘keeping in the heat’. It’s about ensuring a building protects its occupants’ entire well-being and comfort in the following ways.

How well does insulation keep the heat out?

In the UK, thermal insulation to protect from the cold is essential, particularly given ever-increasing energy costs. However, as demand for usable square footage of buildings increases, basement and loft conversions are the routes many now take. However, these parts of a home or office, are the spaces most prone to extremes in temperature. They therefore need more thought – i.e. how do you keep a space warm in winter but, for a loft, how to keep it cool come summer.

Compared with synthetic insulation materials, wood fibre insulation has a much higher density. This higher density means that natural insulation makes for a better heat buffer as the high midday temperature will only reach the internal side and be lost at night when the temperature is already cooler outside.

How a building’s breathability is hurting our health

A breathable structure is one that allows the passage of moisture.

With 90 per cent of all building construction problems associated with water in some way, breathability is essential in measuring a building’s performance and preventing the accumulation of harmful water within the building’s fabric. These are fundamental in reducing health risks from mould, mites that those suffering from respiratory illnesses such as asthma and chronic obstructive pulmonary disease (COPD) are particularly susceptible to.

For effective breathability, there are four essential components that need to be considered:

- a moisture pathway

- a driving force

- a sorptive fabric

- vapour control

Natural fibre insulation is most effective as it suppresses potentially harmful water by binding and releasing moisture which helps regulate humidity levels as the moisture moves.

Easy-to-fit insulation

A well-designed building takes into consideration how a material performs throughout the building’s entire life cycle. This includes ease of installation. Steico’s wood fibre insulation is simple and easy to fit (either packed or friction-fitted), eliminating installer error, keeping construction programmes, tight and costs, low.

How sustainability will save you time and money

While all insulation is helping the environment by limiting energy being burnt for heat, natural fibre insulation materials are comparatively more robust. This means that when it comes to disposal, they can be composted – i.e. no specialist waste facilities or landfill. Throughout their lifecycle they will additionally have a much lower, and often, negative carbon footprint.

More than just protecting your home from fire

All insulations will meet fire safety standards, but this is a minimum rating. The key differentiator between natural and synthetic is that natural insulations will prevent the spread of fire and if burnt, will not give off toxic fumes such as cyanide as polyisocyanurates (PIR) might.

Will the house be standing in 100 years?

Condensation is one of the costliest risks to buildings causing huge maintenance repairs and structural damage. Natural materials are better able to absorb and release water whilst remaining dry meaning it is better able to protect from and buffer moisture thereby becoming a key part of healthy living.

Comfort for occupants

When selecting insulation for a building, there are implications for the health of the occupants, the structure of the building, its impact on the environment, its acoustic properties, durability and carbon footprint.

Cancelling out the noise for a peaceful night’s sleep

The higher density of natural insulations – such as wood fibre – makes them better at reducing noise. Sounds external to the building, such as traffic or music, as well as those from within the building, through walls and ceilings are attenuated better by wood fibre than synthetic equivalents. In providing better protection from acoustic pollutants, occupants often report a building as being more restful and relaxing thereby encouraging better mental health.

When a building is well-designed and well-built, occupants should be at their peak comfort. With the average person spending approximately 80% of their lives in enclosed rooms, an occupant’s well-being is imperative . Therefore, the products used to achieve this, should cover all the issues affecting a building’s construction, its impact on both its occupants and nature.

For a free audit of whether natural insulation’s right for your project, visit www.ecomerchant.co.uk/protexion or call 01793 847 445.

Written by Will Kirkman, managing director at Ecomerchant

Via SIG Tyneside, AIM has supplied the Acoustic Trough Infills for two large roof areas to Wates’ contractor Chemplas, the North East-based roofing, cladding and glazing company.

Via SIG Tyneside, AIM has supplied the Acoustic Trough Infills for two large roof areas to Wates’ contractor Chemplas, the North East-based roofing, cladding and glazing company.