The McCarthy & Stone scheme in Swindon comprises of two blocks accommodating around apartments for the over 60s-B

An EJOT fixing combination, which is designed for rapid installation of flat roof systems with tapered insulation, has been instrumental in market-leading retirement property developer McCarthy & Stone meeting the strict completion deadline at one of its latest developments in Wiltshire.

Pull-out substrate testing prior to specification-B

The scheme at Wichelstowe in Swindon is formed of two blocks which accommodate a range of one and two bedroom apartments designed to offer stylish independent living for the over 60s, with around 120 new properties in total. McCarthy & Stone has co-developed the site with Anchor Hanover Group (Anchor), England’s largest not-for-profit provider of specialist housing and care for people in later life, to deliver a retirement community close to the picturesque Wilts and Berks Canal.

The developer’s firm commitment to delivering the scheme to new residents on time, as promised, meant that the construction team had to pull out all the stops to find creative solutions to keep the build schedule on track. One particular challenge resulted from the relatively small window available to install the extensive flat roofs of the apartment blocks which fell at a time when temperatures had plummeted unexpectedly.

The original proposal was for a tapered insulation system, incorporating a Bauder PVC membrane plus mineral wool insulation, to be bonded to the concrete deck. However, given the cold weather conditions, it was not possible to apply the adhesive during the planned installation window.

As waiting for the temperature to rise to the required level would have resulted in unpalatable delays to the construction programme, nationwide roofing contractor Protec Roofing was tasked with finding a solution that would ensure the proposed flat roof system could still be used.

Protec Roofing’s managing director Ian Green approached EJOT UK’s flat roofing specialist Kevin Rackley for assistance. He had recently been introduced to EJOT’s mechanical fixing solution for flat roof systems involving a combination of the JBS-R fastener and EcoTek tube-washer at an industry event, and after recommending it to the project team, it was subsequently approved for use by Bauder.

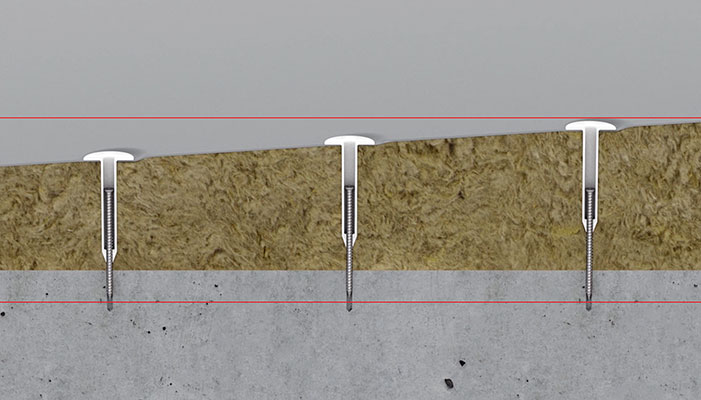

The EJOT JBS-R/EcoTek combination brings together a high-performing organically coated concrete screw (JBS-R 7.5) with a high-quality telescopic tube-washer (EcoTek) to provide a fixing solution that is adjustable to fit the required depth of insulation. It is suitable for all types of commonly used tapered insulation, principally mineral fibre, EPS, XPS and PIR.

3 The system requires fewer combinations and saves valuable time

The combination is suitable for any insulation depth of between 70mm and 590mm, and it has the benefit of requiring fewer fastener / washer combinations than any other current mechanical fixing approach. As a result, fastener use can be significantly rationalised, subject to the application, a site survey and pull-out tests, which EJOT UK is able to assist with.

At the Wichelstowe development, the tapered insulation depth on one of the roofs ranged from 90mm to 330mm, using four lengths of JBS-R fastener of between 80mm and 210mm. The roof on the second building involved insulation depths between 140mm and 380mm, which required three fastener lengths of between 120mm and 210mm.

In addition to keeping the construction schedule on track during the cold weather, the installation process also proved popular with the team on site. Installation of the EcoTek/JBS-R combination is easy because only one embedment depth is needed whatever the insulation thickness. Easy adjustability is also provided through the innovative way that the EcoTek tube-washer is driven into place using a custom tool with the fastener already in place.

Where the roof features a particularly deep layer of tapered insulation to maximise thermal performance, as was the case at Wichelstowe, EJOT’s flanged A-cone and driver bit extension is used to avoid the awkwardness associated with drilling deep using standard SDS drills. This means installers can avoid a highly delicate procedure requiring long-length SDS drills, which are often difficult to source.

The simplified installation process offered by the EcoTek/JBS-R tube-washer and fastener combination also means that fewer on-site calculations were required compared to using other mechanical fixing approaches.

Luke Pickering, Protec Roofing’s site supervisor on this project, said:

“Switching from the proposed bonded application method to using the EcoTek/JBS-R combination proved to offer far more benefits than simply allowing us to continue installation during the cold weather – as critical as this was. We were working with insulation depths of up to 380mm, so we knew the fastening approach would make a huge difference to how efficiently we could work on site, and we were really pleased with how the process worked out.

“The single embedment depth, regardless of the length of fasteners, and how EJOT’s tooling allowed us to make simple adjustments saved a considerable amount of time compared to other mechanical fixings we’ve used in previous tapered insulation projects. The A-cone and extension tooling helped here too, making it easier for our team to drill at the deepest point and achieve a consistent efficiency and quality across the roof area.”

Long term performance is assured when using the JBS-R/EcoTek fastening system given the quality materials used to manufacture both fastener elements. The JBS-R fastener is manufactured from case hardened steel and the EcoTek tube-washer is formed from high quality plastic to provide a lasting solution.

Kevin Rackley is EJOT UK’s Business development Manager for Flat Roofing products:

“The Wichelstowe project is a perfect example of how the EcoTek/JBS-R combination can contribute to more efficient construction and help developers avoid site delays due to the UK’s highly unpredictable weather.

“We offered two options to mechanically fix the Bauder membrane and the mineral wool insulation – one using the JBS-R system and the other using one of our other concrete screws, the FBS-R. Both would have provided an effective fixing solution, but with fewer different lengths of the JBS-R required, we could help the Protec Roofing team rationalise fastener use as much as possible for a more streamlined installation process.”

The EcoTek/JBS-R combination is part of EJOT’s extensive range of fastening solutions for flat roofing, encompassing fully mechanical and part-bonded systems, and fully compliant with the guidelines published by the Single Ply Roofing Association (SPRA). Flat roof designers, contractors and installers benefit from highly specialised support from the EJOT UK team at all stages of the flat roofing project to ensure all the performance objectives can be met without compromise.

CLICK HERE TO FIND OUT MORE

Martyn Holloway, Business Development Manager, Flat Roofing for SFS, comments:

Martyn Holloway, Business Development Manager, Flat Roofing for SFS, comments: