Michael Simpson, Technical Advisor at SFS

SFS Group Fastening Technology’s Construction Division is the world’s largest manufacturer and distributor of carbon and stainless-steel fastening solutions for roofing, cladding and façade systems. Additionally, SFS manufactures an award-winning fall protection range, innovative rainscreen subframe systems and high-quality hinges for windows and doors. The reputation of this established company, which has been in the UK for over 120 years, rests on value added propositions along with company-wide technical expertise.

Here, Michael Simpson, technical advisor at SFS, talks about his role in helping clients find solutions to their construction challenges.

How long have you worked at SFS?

I have worked for SFS since January 2024.

What were your previous roles?

I have 28 years’ experience in the cladding industry. I’ve done pretty much everything from installing a wide range of rainscreen cladding systems, overcoming technical issues, negotiating with clients and specifiers all whilst managing several projects and training and supervising numerous installation teams.

What do you enjoy most about your job?

I just love cladding and love working with people to get the job done! I now have direct contact with customers and enjoy talking them through all aspects of their projects and helping them find solutions to the most challenging jobs.

What has been the most exciting project you have worked on with SFS?

I was involved with installation trials and photoshoots for a new product launch recently which involved me demonstrating the new system in front of the camera. That was a real buzz!

What new ideas and strategies are you working on at the moment?

I’ve got so many ideas and suggestions based on my wealth of knowledge; I am currently deeply engaged in testing some of the upcoming new SFS ConnectSuite of free online tools. Strategically, I view my work as a way to secure the future of my customers by offering excellent, yet practical advice based on my experience.

Describe how you provide technical support to customers?

Our priorities include providing our customers with the technical support they need by making recommendations based on our SFS NVELOPE subframe and fixing systems. This uses fantastic tools such as Project Builder. I like to think my installation know-how learned over many years, adds another level of expertise to our service as I have first-hand knowledge which enables me to visualise what a customer describes to really understand the detail and requirements.

When SFS introduces a new product, do you undertake training to get to know the product and its application to help you assist customers?

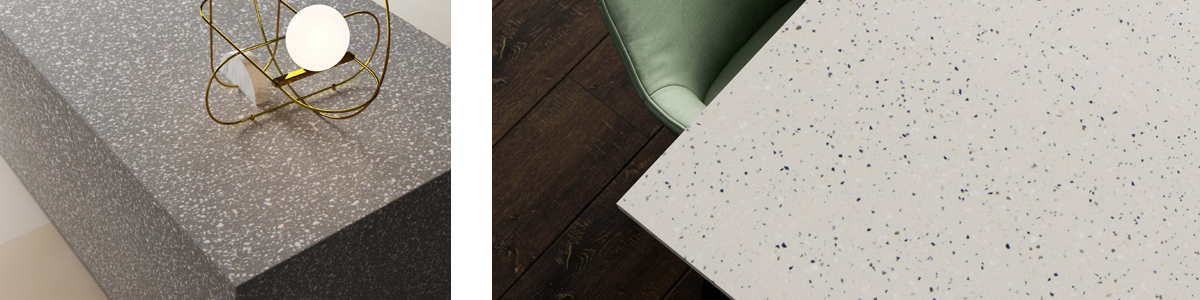

Yes, I’ve already supported the launch of our SFS NVELOPE NVS RP system. I really enjoyed this. I’m always interested in seeing new SFS products so I can gain the best understanding of how it works so I can help our customers to get the best solution for their projects.

How does the technical department fit in with other departments at SFS UK?

I’m part of our SFS Technical Team headed up by our UK Technical Manager, Gordon Hines. We support all technical enquiries for our building envelope product lines, including rainscreen, roofing & cladding and fall protection. We are always on hand to support our sales team so they can offer their customers a knowledgeable service.

Which other departments do you provide support and advice to?

Any department that requires our expertise. This could be supporting our marketing or customer experience team as an example, with any technical advice or updates as necessary

CLICK HERE to visit the SFS Website

or for further information, call 0330 0555888

a whole. As such, an organisation or brand cannot, in itself, gain assessment or make any claims of conformance beyond a specific product set.

a whole. As such, an organisation or brand cannot, in itself, gain assessment or make any claims of conformance beyond a specific product set.