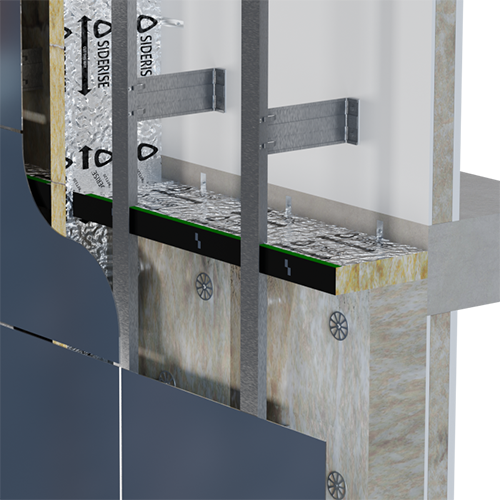

Siderise has successfully completed the Code for Construction Product Information (CCPI) assessment process for its RH Horizontal and RV Vertical Cavity Barrier for cladding applications, and CT Cavity Tray and EW Cavity Barrier and Firestop for masonry external wall systems. With approval already gained for its CW-FS Firestop range for curtain walling earlier in the year, this means all the company’s main passive fire protection ranges now carry this best-practice mark, providing greater confidence that the information surrounding them is “clear, accurate, up-to-date, accessible and unambiguous.”

To gain a CCPI mark, companies are subject to a rigorous and independent assessment process, which includes assessing that the leadership and business culture aligns with the ethos of the CCPI, as well as providing information and clear evidence of conformance to each of the Code’s applicable eleven clauses. In line with its long-term commitment to ‘integrity in all we do’, achieving CCPI conformance for these core product ranges is just one part of the Siderise’s wider strategy to support accurate specification and a safer built environment. Siderise Technical Director, Lee Nichols, explained:

“Following the introduction of the Building Safety Act and particularly of Gateway 2 for higher-risk buildings (HRBs), we understand that specifiers— whether they are architects, fire engineers or contractors— must feel confident in the information they are using to make decisions and be able to access robust and assessed product data in the format they need. We have aligned getting the CCPI mark for our core products with developing a more holistic specification support package, including creating Specification Packs that summarise the relevant product information for the designated application, and building our partnership with the NBS.”

“By having our core product ranges assessed by the Code, we have not only made a commitment to continuous improvement as the product set remains registered with the CCPI, but we hope to communicate to our customers that we are actively responding to the challenges they face when it comes to product information —helping the industry to raise its collective understanding of the crucial importance of fire safety and fire testing. ”

CLICK HERE

For more information about Siderise and to explore its product data

“Following the introduction of the Building Safety Act and particularly of Gateway 2 for higher-risk buildings (HRBs), we understand that specifiers— whether they are architects, fire engineers or contractors— must feel confident in the information they are using to make decisions and be able to access robust and assessed product data in the format they need. We have aligned getting the CCPI mark for our core products with developing a more holistic specification support package, including creating Specification Packs that summarise the relevant product information for the designated application, and building our partnership with the NBS.”

“Following the introduction of the Building Safety Act and particularly of Gateway 2 for higher-risk buildings (HRBs), we understand that specifiers— whether they are architects, fire engineers or contractors— must feel confident in the information they are using to make decisions and be able to access robust and assessed product data in the format they need. We have aligned getting the CCPI mark for our core products with developing a more holistic specification support package, including creating Specification Packs that summarise the relevant product information for the designated application, and building our partnership with the NBS.” The Silverliner 5 has been officially launched this month following rigorous testing and has been designed to provide robust passive fire protection. It has been developed in response to the high demand for a mid-range open state cavity barrier solution where a higher specification 120 minute (EI) system is not required.

The Silverliner 5 has been officially launched this month following rigorous testing and has been designed to provide robust passive fire protection. It has been developed in response to the high demand for a mid-range open state cavity barrier solution where a higher specification 120 minute (EI) system is not required.