Millom Rugby Union Football Club situated in the scenic Cumbrian countryside, is a multi-use facility that includes rugby pitches and a popular caravan and camping ground. The club required a reliable, energy-efficient hot water solution to replace its traditional stored hot water supply.

The system was required to meet a high and variable demand from matchday players, onsite staff, and campsite visitors who demand comfort and safety. The variable nature of demand created multiple peaks in supply throughout the day.

The site is off-grid and reliant on LPG, and initial plans to connect to mains gas were abandoned due to the prohibitive cost and limitations of the existing infrastructure – therefore Rinnai LPG to BioLPG hot water system were seen as both an economically and ecological route to lower costs and carbon.

After consultation with Rinnai engineering experts the Club installed four N Series 1600 continuous flow water heaters all supplying instant temperature accurate hot water on demand for all players and caravan site visitors.

Originally a stored water system was proposed but Rinnai’s engineering team provided a full CAPEX, OPEX, and lifecycle cost analysis as standard. This demonstrated that an LPG and BIOLPG ready continuous flow system would outperform a traditional stored hot water system in terms of:

- Energy efficiency

- Operational cost savings

- Carbon footprint reduction

- System longevity and reliability (up to 12 years warranty)

All Rinnai appliances are manufactured under strict guidelines of ISO 9001 quality management and ISO 14001 environmental management. The commercial continuous flow water heaters are designed to provide almost limitless volumes of cost-effective and temperature controlled hot water.

Each Rinnai N Series gas fired water heaters offer a more compact and enhanced combustion design that allows for convenient installation, superior operational performance, and easy accessibility when servicing is required. All additional components are designed and manufactured by Rinnai ensuring proven quality and reliability.

The Rinnai N Series is the first ever continuous flow water heater manufactured with stainless steel heat exchangers to be available in the UK – this provides an extended working life at optimum performance to each of the four models in the range.

Features include:

Flue up to 48+ metres for concentric for flexible mounting

Turbo Fan and longevity

Built-in controller as standard on both internal and external models for easy set up

Cascade Cable assembly allows up to twenty-four water heaters to be connected and function as one total and complete system. Any number of N-series Rinnai water heaters can be manifolded together enabling the largest capacities on the market.

Frost Protection – minus 15°C on the internal versions and minus 20 °C on the external versions for flexible installation

Temperature setting up to 85 degrees for legionella protection or high temperature projects

Maintenance Monitor for engineers for easy system updates, diagnostics or set up.

And one small point for history buffs:- across town is the Millom Rugby LEAGUE Football Club – it is the oldest amateur rugby league club in the world, having been founded in 1873.

Rinnai’s H3 range of products include domestic and commercial heat pumps that offer immediate property decarbonisation. Rinnai is determined to provide UK customers with cost effective low carbon solutions towards domestic and commercial hot water and building heating provision.

RINNAI’S H3 DECARBONISATION OFFERS PATHWAYS & CUSTOMER COST REDUCTIONS

FOR COMMERCIAL, DOMESTIC AND OFF-GRID HEATING & HOT WATER DELIVERY

www.rinnai-uk.co.uk/about us/H3

Rinnai’s H3 range of decarbonising products include hydrogen / BioLPG ready technology, hybrid systems, and a wide range of LOW GWP heat pumps and solar thermal. Also, within Rinnai’s H3 range is Infinity hydrogen blend ready and BioLPG ready continuous flow water heaters which are stacked with a multitude of features that ensure long life, robust & durable use, customer satisfaction and product efficiency.

Rinnai’s range of decarbonising products – H1/H2/H3 – consists of heat pump, solar, hydrogen in any configuration, hybrid formats for either residential or commercial applications. Rinnai’s H3 range of products offer contractors, consultants and end users a range of efficient, robust and affordable decarbonising appliances which create practical, economic and technically feasible solutions. The range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters.

Rinnai H1 continuous water heaters and boilers offer practical and economic decarbonization delivered through technological innovation in hydrogen and renewable liquid gas ready technology.

Rinnai’s H1 option is centred on hydrogen, as it is anticipated that clean hydrogen fuels will become internationally energy market-relevant in the future; Rinnai water heaters are hydrogen 20% blends ready and include the world’s first 100% hydrogen-ready hot water heating technology.

Rinnai H2 – Decarbonization simplified with renewable gas-ready units, Solar Thermal and Heat Pump Hybrids. Rinnai H2 is designed to introduce a practical and low-cost option which may suit specific sites and enable multiple decarbonisation pathways with the addition of high performance.

Rinnai H3 – Low-GWP heat pump technology made easy – Rinnai heat pumps are available for domestic and commercial usage with an extensive range of 4 – 115kW appliances.

Rinnai’s H3 heat pumps utilise R32 refrigerant and have favourable COP and SCOP.

Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

Rinnai’s commercial and domestic continuous flow water heaters offer a limitless supply of instantaneous temperature controlled hot water and all units are designed to align with present and future energy sources. Rinnai condensing water heaters accept either existing fuel or hydrogen gas blends. Rinnai units are also suited for off-grid customers who require LPG and BioLPG or DME.

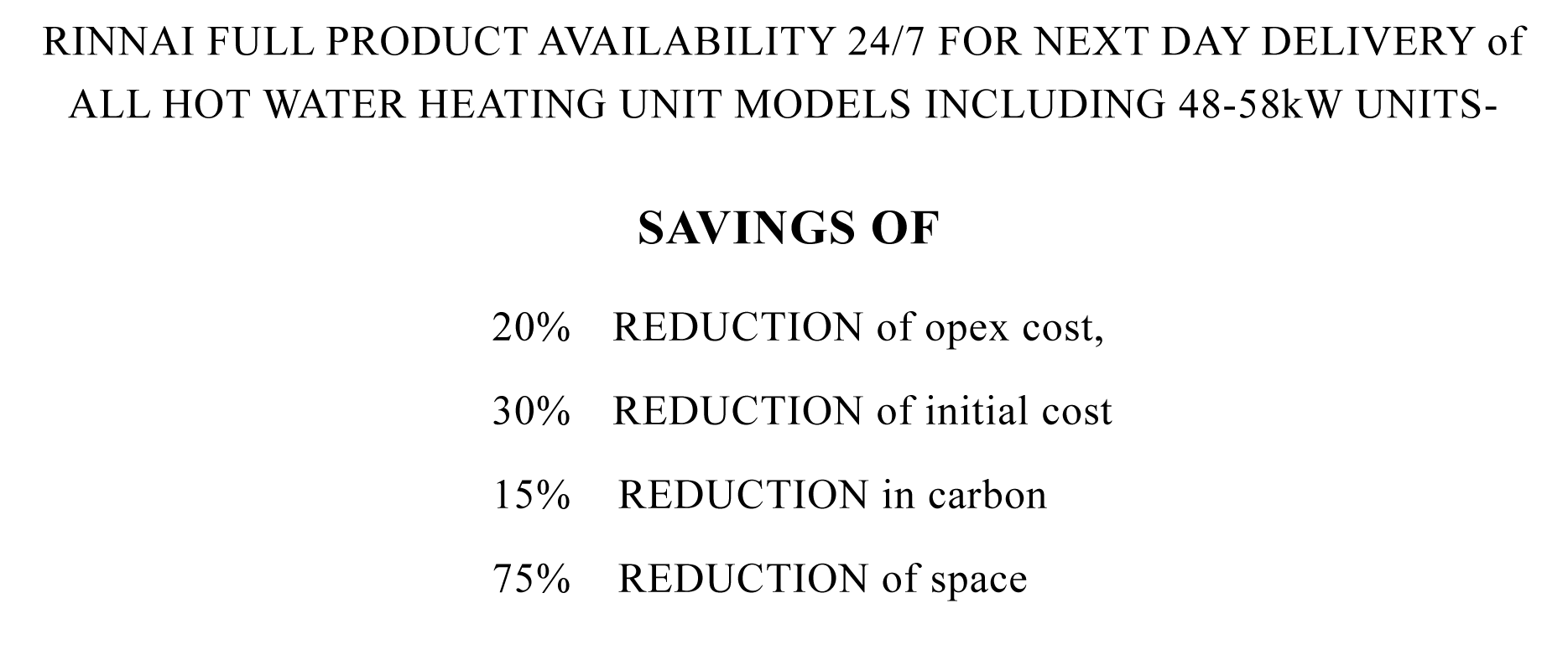

Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours. Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question. Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s.

CLICK HERE TO VISIT THE RINNAI WEBSITE

or HERE to EMAIL RINNAI

CLICK HERE For more information on the RINNAI product range