Sustainable Synthetic Building Materials

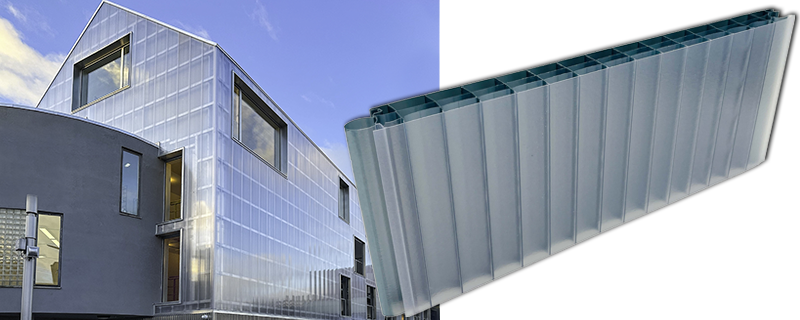

Synthetic material is proving to be versatile and adaptable, particularly as a building material. In some cases, it even represents a more ecological alternative to other raw materials. As one of the leading manufacturers of polycarbonate light building elements, Rodeca proves that synthetic material has environmentally friendly properties. The translucent panels are characterized, among other things, by their durability, energy efficiency and recyclability.

Synthetic materials have many properties that can be influenced. Hardly any other material is so versatile and can be used in so many ways – from disposable bottles, colorful children’s toys or CDs, to clothing and building materials.

Production basics

Synthetic materials are solids made from artificial or partially artificial polymers. These in turn are made up of repeating monomer units. Based on their physical properties, polymers are divided into three groups: Thermosets, elastomers and thermoplastics. The latter can be repeatedly deformed above a certain temperature. In addition to polycarbonate, some examples of thermoplastics are polyethylene, polypropylene and PVC. The production of polycarbonate can sometimes consume less energy than the production of other materials. For example, the melting and molding processes for glass require high temperatures, which means a considerable amount of energy. Furthermore, polycarbonate can have very different properties depending on the base material, manufacturing process and admixture of additives. As a result, it is impossible to imagine the automotive, aviation and electrical industries, construction and architecture without polycarbonate.

Long-term durability and service life

One challenge is that many everyday synthetic items – such as plastic bags or plastic lids – have a short service life but remain in the environment for centuries. However, there are certainly areas in which synthetic materials are a more sustainable alternative to other materials from a life cycle assessment perspective. With an average service life of around 30 years, polycarbonate panels from Rodeca offer a long-lasting solution for building façades. Provided with a co-extruded UV protection layer, the elements are effectively protected against the effects of solar radiation. In addition, the UV protective layer maintains the high hail resistance and light transmission over a long period of time, while significantly slowing down the natural ageing of the panels. High resistance to other weathering influences and chemical substances is also guaranteed.

Light building elements that reduce energy consumption

However, the Rodeca products not only score points for their long service life: the polycarbonate façade elements increase the energy efficiency of a building in a variety of ways. Thanks to their translucency, daylight illuminates the interior, which significantly reduces the need for artificial lighting. At the same time, the panels provide shading to reduce the heat input from direct sunlight, which in turn reduces the energy required for air conditioning. The multi-shell structure of the Rodeca façade elements serves as additional insulation. This effect, combined with the high thermal insulation of the polycarbonate, reduces the building’s heating and cooling requirements. Energy balance analyses underline the low fuel requirement for heating an industrial building with polycarbonate panels compared to buildings with glass windows. In addition, their low weight also facilitates construction and installation. This is a particular advantage in the case of refurbishment – additional structural strengthening of the building is often not necessary. Conversions and contemporary upgrades are therefore easier to realize in an environmentally friendly and sustainable way.

Rodeca shows that polycarbonate can be a sustainable solution for synthetic material applications. This is because the light building elements are characterized by high durability, recyclability and energy efficiency. Furthermore, Rodeca remains committed to pushing the boundaries of sustainability and innovation in the construction sector, always keeping the environmental impact of its products in mind.

Leave a Reply

Want to join the discussion?Feel free to contribute!