London’s new super sewer

Costain, as part of joint venture with VINCI Construction Grands Projets and Bachy Soletanche, was awarded the contract for the East works package of the Thames Tideway Tunnel, the UK water industry’s biggest Combined Sewer Overflow (CSO) project.

The Eastern section spans six sites and 10km of tunnels. After ten years of construction, the last of 21 connections has been made between the original Victorian sewers and the new 25km Thames Tideway Tunnel, bringing the entire system online to support a growing population and economy, and protect the tidal Thames from sewage pollution.

The project is on track to be fully finished (with testing complete) later in 2025. Thames Water will then operate the system as part of its London wastewater network.

The project

London relied on a 150-year-old sewer system built for a population less than half its current size. The system needed to be made fit for the 21st century and help prevent millions of tonnes of sewage pollution entering the river each year.

The Tideway project was tasked with designing and building tunnels to capture the capital’s wastewater and stormwater, and diverting it to treatment plants.

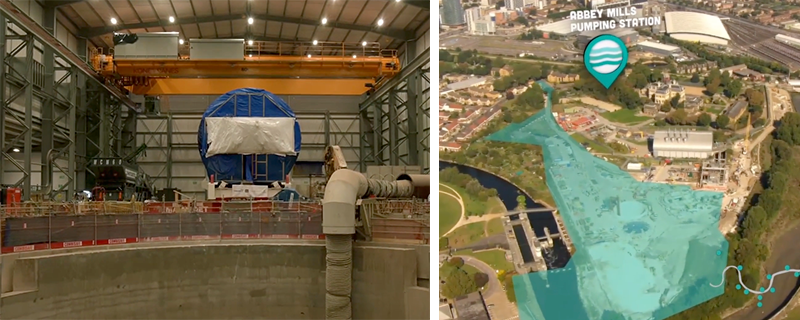

Costain and its JV partners have been delivering the eastern section of Tideway which consists of a tunnel from Chambers Wharf in Bermondsey to Abbey Mills Pumping Station in Stratford, along with a smaller connection tunnel from Greenwich Pumping Station to Chambers Wharf.

Our approach

Costain’s approach to production thinking – which combines modern methods of construction with new technologies – has built efficiencies into the project from the start. This included prototyping, building and testing assets before design freeze, whilst quality controls for civils and Mechanical, Electrical, Instrumentation, Control and Automation (MEICA) tests were completed off-site before installation. The MEICA approach was based on repeatable solutions that would be straightforward for operators and maintainers to use. As such, we procured instrumentation that would run on software control blocks across the alliance of eight main works contractors, with a standardised user interface for ease of training and to promote consistency.

Collaborating at a portfolio level

The success of the project has been the result of close collaboration with Tideway and works contractors across the portfolio. Costain led the standardisation of products and design standards, including all O&M and MEICA. Bulk procurement was cost effective, and the main benefit was ensuring Tideway would be familiar with the asset at handover.

We have implemented an alliance-wide procurement strategy, promoting local sourcing throughout the project. We also maximised local spend by using a local supply chain, facilitated open competition for nearby businesses and provided clear visibility of the procurement programme.

The solution

The pumping stations at Earl and Greenwich required flows to be maintained through existing sewers during the interception works. This was achieved using precast technology and phased construction to transfer the flows from the sewer outfall through the new structure once complete. The complete works have involved installing flap valves, penstocks and passive ventilation structures.

The production thinking approach and the embedding of lean principles and efficiencies into the commissioning programme have resulted in project delivery times falling from 18 to 11 months through improving definitions and creating a targeted sequence of testing.

Building in these efficiencies has paved the way for an optimised delivery and the project is set to achieve the required dates for system commissioning, whilst the implementation of a lean construction methodology has achieved £1m in cost reductions.

Other savings have come from automating specific processes. These include method statements, red line drawing systems and improvements to timesheets, which have saved more than 6,000 hours of labour and £85,000 per year.

Key benefits

Delivering sustainable outcomes

There have been significant carbon savings across the project. On the five shafts, the concrete for the base slab has been reduced by c.55%, whilst a ground-granulated blast furnace slag using 1500m3 of concrete rather than 3500m3 and saving 750 tonnes of CO2 emissions was proposed.

The use of a thinner secondary lining has resulted in reducing the use of concrete by a fifth across the project as a whole – over 11,000m3 – and saved 4,500 tonnes in CO2 emissions. In addition, 330 fewer tonnes of steel have been used, equating to a saving of 800 tonnes in CO2.

We have also pioneered a sustainable approach to boost biodiversity and carbon reduction efforts.

Highlights include:

- Used rainwater harvesting to save a predicted 11,678,210 litres of water during the tunnelling phase.

- The world’s first electric hydrofraise (a rotary trench cutting machine used to dig the shaft for the main tunnel) resulted in significant reductions in carbon emissions, noise and air pollution.

- Tideway’s More by River strategy which aimed to limit road use. Where possible, material from tunnelling work, as well as incoming construction materials including tunnel boring machines, have been moved by barges on the river rather than HGVs. By August 2024, the scheme had resulted in 5.8 million tonnes of material transported by river, 688,000 fewer HGV journeys and a reduction of 24,400 tonnes in carbon emissions (compared to the HGV equivalent).

- Barges have also taken waste to nearby salt lagoons to support habitat creation and enable a biodiversity net gain of 6.5%.

Driving prosperity for local communities

The project has created more than 4,000 direct jobs and thousands more indirectly. It has offered hundreds of apprenticeships and work placements and has been committed to employing local people, women returners, ex-offenders and ex-military personnel.

Initiatives pioneered include a scheme funded by the Construction Industry Training Board that aims to get homeless and vulnerable people get back into work. It has been specifically targeted at people living in boroughs where Tideway’s main sites are based, and provides interview preparation and practice, health and safety training, work experience and a guaranteed interview for full-time employment on the Thames Tideway Tunnel.

Another programme, ‘Breaking Barriers’, has aimed to increase employability and promote careers in STEM for teenagers, whilst also channelling the focus on the river with London Youth Rowing to support young people to achieve their potential.

During certain periods, 25% of staff working on Tideway have been from the 14 local boroughs, 36% of staff in the client and programme management team have been women, and 37 people with previous convictions have been employed on the project.

Source: Costain

Leave a Reply

Want to join the discussion?Feel free to contribute!