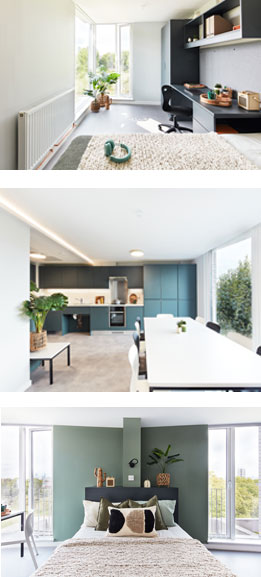

Alumno, a specialist student accommodation developer, conceived and delivered a sophisticated and welcoming space for Element Bermondsey, a new student accommodation overlooking Bermondsey Spa Gardens. To do this, Forbo Flooring Systems’ Sarlon and Safestep floor coverings were specified, for their technical and aesthetic qualities.

Operated by CRM Students, the UK’s leading independent student accommodation management brand, Element Bermondsey provides 143 students living in Southwark with high-quality, fully serviced and sustainable accommodation. Greenaway Architecture and Tatham Studios worked with Alumno, to create contemporary spaces for the increasing number of students coming into London to study.

Greenaway Architecture and Alumno took the reins when designing Element Bermondsey, as Ron Plunz, Development Director at Alumno explained:

“We had agreed a palette with our funding partner during our initial design meetings, which we had presented to them in a CGI format. We then took this vision and fine-tuned it to get a much clearer idea of the direction we wanted to go in.

“When designing student accommodation, we usually opt for a neutral theme as there is a mix of cultures, ages and people living under one roof. By choosing a contemporary yet neutral palette, it provides students with the freedom to make the spaces their own.”

Not only was it important that Alumno created a space that allowed the residents to express themselves, but it was also key that the building met sustainability requirements. Ron explained further: “We really wanted and needed to achieve a BREEAM rating of ‘Excellent’ with this building. As such, one of the factors we wanted to address was noise levels, to create healthy and comfortable spaces for the students. It was for this reason that we specified Forbo’s Sarlon acoustic floor covering; with a 19 dB impact sound reduction it exceeded the requirements needed for this accreditation.”

Not only was it important that Alumno created a space that allowed the residents to express themselves, but it was also key that the building met sustainability requirements. Ron explained further: “We really wanted and needed to achieve a BREEAM rating of ‘Excellent’ with this building. As such, one of the factors we wanted to address was noise levels, to create healthy and comfortable spaces for the students. It was for this reason that we specified Forbo’s Sarlon acoustic floor covering; with a 19 dB impact sound reduction it exceeded the requirements needed for this accreditation.”

Forbo’s Sarlon 19 dB was specified in two different colours for this project. Ron explained:

“We used Sarlon in Silver Concrete for the hallways and kitchen areas and Anthracite Nairobi in the bedrooms; both are deep greys, which offer an attractive, neutral baseline for the rooms, whilst providing some warmth to the spaces. I like to use products with some natural patterns like stone, concrete or textile weaves as it can serve a dual purpose of forming a pattern, whilst also helping to hide marks, which keeps the room looking smart.

“Forbo’s Sarlon offering fits this perfectly as it is available in a range of natural patterns and a versatile range of colours. We always use Forbo as its product range is just so varied, full of aesthetically pleasing designs that fit the technical requirements we’re looking for.”

Not only this, but the XtremePUR finish ensures Sarlon delivers improved scratch resistance, which is important for student accommodation as it endures heavy use across an academic year. Additionally, Sarlon is phthalate free, minimising the impact it has on the residents’ wellbeing.

Furthermore, Forbo’s Safestep product was used in the ensuite bathrooms, offering a good level of slip resistance. Ron continued:

“Obviously resident safety is extremely important for these types of projects. So, for this reason, we needed a floor covering that could satisfy our health and safety requirements, but one that didn’t look industrial. Forbo’s Safestep was the perfect solution, with the contemporary Lava colour, which is a dark grey shade with hints of green running throughout it. It suits the neutral palette of the room, but also provides a good level of slip resistance.

“Forbo has a wide range of options available. In fact, there’s a solution for all applications, which makes our job easier, as we don’t have to use multiple manufacturers. Instead, we can purchase all the floor coverings we need from one company.”

CRM Students welcomed students into this latest scheme at the start of the 2022 academic year and has received positive feedback from the residents and press.

CLICK HERE for information about Forbo’s product range for student accommodation

The design features a colonnade sweeping across the front of the building echoing the curve of the spine road and a new public space. The column spacing guides occupants and visitors to the entrance – a GEZE

The design features a colonnade sweeping across the front of the building echoing the curve of the spine road and a new public space. The column spacing guides occupants and visitors to the entrance – a GEZE  “Operating within a business-to-business environment, we talk to all sorts of prospective customers and clients: from architects and developers to architectural ironmongers and installers. Every person will have different levels of knowledge which may require varying advice and support. Fortunately, we have an experienced team with extensive experience across the business.

“Operating within a business-to-business environment, we talk to all sorts of prospective customers and clients: from architects and developers to architectural ironmongers and installers. Every person will have different levels of knowledge which may require varying advice and support. Fortunately, we have an experienced team with extensive experience across the business.

One-step cable installation saves time and effort, and speeds up and simplifies the installation process.

One-step cable installation saves time and effort, and speeds up and simplifies the installation process.