Rinnai is issuing a ‘White Paper’ report that details the potential limitations of manufacturer-issued efficiency measures for Heat pumps, namely COP (Coefficient of performance) and SCOP (Seasonal Coefficient of Performance).

Manufacturers often measure heat pump efficiency using Coefficient of Performance (COP), which is the ratio of useful heat energy produced to the electricity consumed at a specific external air temperature and temperature rise required.

Due to the way in which efficiency is measured utilizing a SCOP rating, commercial hot water systems (CHWS) will potentially show a lack of system congruity when considering the entire system, against the expected performance of the heat pump alone, which, as a consequence, affects product expectations and ultimately carbon reductions.

Instead, the Rinnai White paper has adopted the ‘Seasonal Performance Factor’ which evaluates all energy utilizing components within a commercial hot water system, therefore, measuring the performance of the entire system as opposed to solely the heat pump.

This Rinnai White Paper on SPF, authored by Sean Ehlen M Eng, also presents a detailed case study to underline the two systems of thought used within the hot water dispersal industry. These are used to inform potential customers of a system’s efficiency.

By presenting this White Paper to UK customers, Rinnai aims to provide information that delivers a concise and true account of commercial hot water performance using the ‘Seasonal Performance Factor’ methodology.

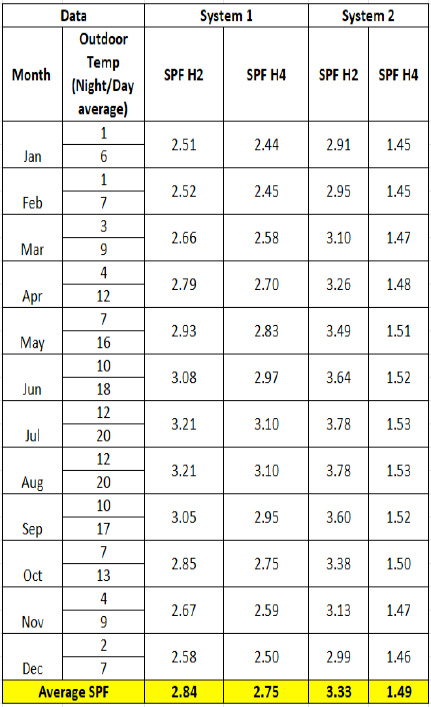

The case study presents two heat pump systems:

System 1 covers the DHW demand with 100% heat pump;

System 2 uses 40% heat pump and includes an electric cylinder to provide back-up heat.

The results show that when considering the entire commercial hot water system, including the buildings’ piping system, System 1 has a higher SPF (2.75) than System 2 (1.49), due to System 2 operating the back-up heater in peak times and to recover secondary system heat losses.

However, when observing the SPF of only the heat pump unit, System 2 is higher. This can mislead the customer as they are expecting an SPF of close to 3.33, but the system only performs to an SPF of 1.49, as seen in table 2.

Therefore, the purpose of this White Paper is to highlight the difference in performance between differing system boundaries and works towards informing the customer of the reality of their CHWS.

Rinnai will continue to inform the UK customer of details that provide an accurate statement of system performance, while considering the effects on operational expenditure, economic investment, and environmental impact. Rinnai understands the significance of an investment during a time of sensitive energy costs. Rinnai aim to share all information that assists the UK customer in decision making that saves money and emissions.

RINNAI’S H3 DECARBONISATION OFFERS PATHWAYS & CUSTOMER COST

REDUCTIONS FOR COMMERCIAL, DOMESTIC AND

OFF-GRID HEATING & HOT WATER DELIVERY

CLICK HERE TO FIND OUT MORE ABOUT RINNAI

Rinnai’s H3 range of decarbonising products include hydrogen / BioLPG ready technology, hybrid systems, and a wide range of LOW GWP heat pumps and solar thermal. Also, within Rinnai’s H3 range is Infinity hydrogen blend ready and BioLPG ready continuous flow water heaters which are stacked with a multitude of features that ensure long life, robust & durable use, customer satisfaction and product efficiency.

Rinnai’s range of decarbonising products – H1/H2/H3 – consists of heat pump, solar, hydrogen in any configuration, hybrid formats for either residential or commercial applications. Rinnai’s H3 range of products offer contractors, consultants and end users a range of efficient, robust and affordable decarbonising appliances which create practical, economic and technically feasible solutions. The range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters.

Rinnai H1 continuous water heaters and boilers offer practical and economic decarbonization delivered through technological innovation in hydrogen and renewable liquid gas ready technology.

Rinnai’s H1 option is centred on hydrogen, as it is anticipated that clean hydrogen fuels will become internationally energy market-relevant in the future; Rinnai water heaters are hydrogen 20% blends ready and include the world’s first 100% hydrogen-ready hot water heating technology.

Rinnai H2 – Decarbonization simplified with renewable gas-ready units, Solar Thermal and Heat Pump Hybrids. Rinnai H2 is designed to introduce a practical and low-cost option which may suit specific sites and enable multiple decarbonisation pathways with the addition of high performance.

Rinnai H3 – Low-GWP heat pump technology made easy – Rinnai heat pumps are available for domestic and commercial usage with an extensive range of 4 – 115kW appliances.

Rinnai’s H3 heat pumps utilise R32 refrigerant and have favourable COP and SCOP.

Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

Rinnai’s commercial and domestic continuous flow water heaters offer a limitless supply of instantaneous temperature controlled hot water and all units are designed to align with present and future energy sources. Rinnai condensing water heaters accept either existing fuel or hydrogen gas blends. Rinnai units are also suited for off-grid customers who require LPG and BioLPG or DME.

Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours. Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question. Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s. More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

![]()

Xboxer Universal is available in three models – UNIX-220, UNIX-360 and UNIX-580 – with the largest model having enough duty to ventilate a cluster of up to 12 rooms. The easy to use three speed controls are included as a standard feature, allowing full adjustability for site requirements. Each size is equipped with an integral mounting bracket, helping to reduce installation time no matter the project. Multiple spigot options are available, making the unit fully compatible with circular or rectangular ducting.

Xboxer Universal is available in three models – UNIX-220, UNIX-360 and UNIX-580 – with the largest model having enough duty to ventilate a cluster of up to 12 rooms. The easy to use three speed controls are included as a standard feature, allowing full adjustability for site requirements. Each size is equipped with an integral mounting bracket, helping to reduce installation time no matter the project. Multiple spigot options are available, making the unit fully compatible with circular or rectangular ducting.