Zentia, the UK’s market leader in complete ceiling solutions, is excited to announce the launch of its new Product Selector tool, designed to streamline the product selection process and offer recommended solutions for every project. Available on the Zentia website, the Product Selector makes it easier than ever for architects, designers, and specifiers to find the perfect product for their specific requirements.

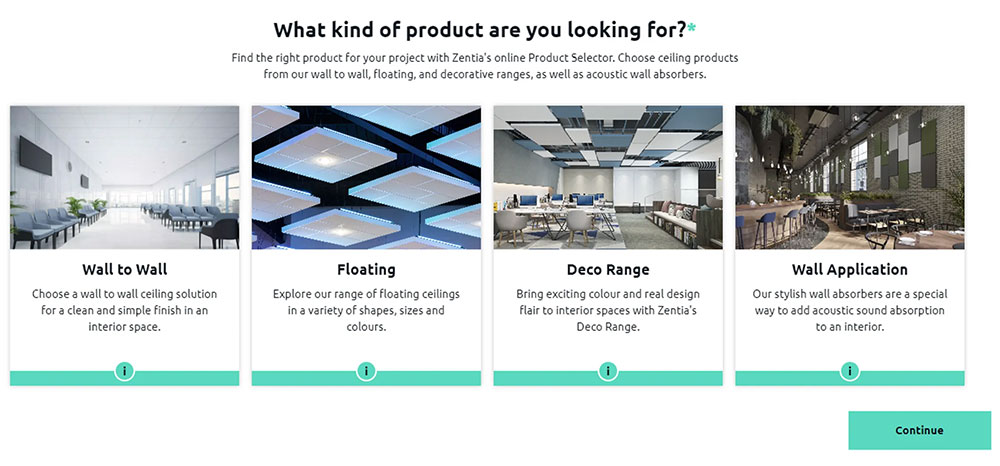

The Product Selector tool is user-friendly and intuitive, allowing users to enter key project details such as sector, room type, colour, material, and shape. Based on the provided criteria, the tool offers recommendations, identifying the ideal product for the project and presenting alternative options. The recommendations are designed to match the specific demands of a wide range of sectors, including education, healthcare, and commercial spaces.

Another key feature of the Product Selector is instant access to useful resources. After receiving product suggestions, users can immediately access relevant product documents, download PDF information packs or request samples and additional specification support.

Whether your project calls for superior acoustic performance in educational environments, infection control in healthcare facilities, or striking design elements in commercial spaces, Zentia’s Product Selector offers reliable, high-quality ceiling system options to meet any challenge.

Michael Anderson, Head of Architectural and Design Consultancy, at Zentia commented on the new tool:

“At Zentia, we are committed to enhancing the specification experience for our customers. With our extensive range of ceiling solutions, we understand that finding the right product can sometimes be overwhelming. The Product Selector tool makes this process easy and seamless, ensuring our customers can find exactly what they need in just a few clicks.”

Zentia’s commitment to innovation and customer service goes beyond providing exceptional ceiling solutions. The launch of the Product Selector is testament to Zentia’s dedication to being a trusted partner in delivering products that perform, inspire, and stand the test of time.

CLICK HERE to experience the new Product Selector tool