A Cumbrian couple has built an ‘Ikea-style,’ carbon-negative home from scratch – with the assembly of the structure being complete in a total of just 12 days.

Surrounded by volunteers and helpers, first time self-builders Beki Winter and her partner Alastair Reeves, started work on the frame of their property near Kendal, at the beginning of last month using a system called WikiHouse.

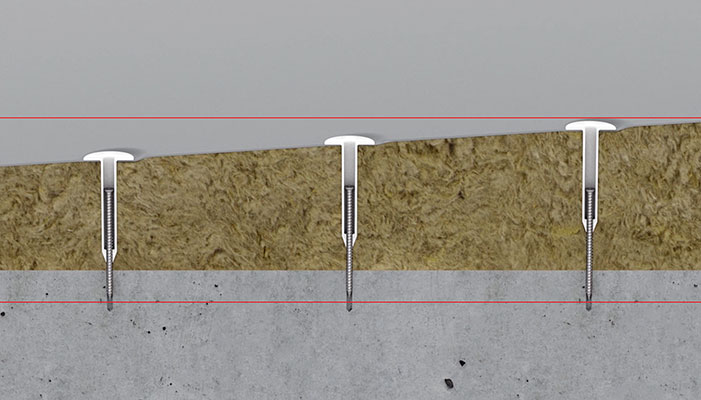

Designed by Manchester-based community-led architects, Architecture Unknown, the impressive family home has been built using cleverly jointed pieces of plywood that essentially fit together like a giant jigsaw puzzle. Each section of the design is cut and crafted by Ulverston’s Digital Woodoo CIC and delivered like Ikea-flat pack furniture ready to build.

The construction of this completely bespoke house has taken place across April, with the home now ready for interior fit out.

Pulling in the help of over 20 volunteers, Beki and Alastair, have built a 3-bed home, with 3-bathrooms, a double height kitchen, dining and reception room for their family as part of a co-housing site.

The build is one of the first of its kind in Cumbria. A low-carbon, sustainable and simple solution to construction, WikiHouse allows people to build affordably whilst retaining a high level of quality and finish.

The couple were given the opportunity to build on the Holme House Farm community site in 2023 when they applied to join the community-led company that runs the site and is owned completely by residents.

After selling their property, Beki and Alastair moved their young family to the site in December 2024. They are currently living out of a static caravan, to enable the start of the build.

Beki Winter, who works in community housing, said:

“We never really thought about whether we wanted to do a self-build, but when the offer presents itself it’s hard to turn down. We knew we weren’t going to build in the traditional sense start to finish because we didn’t have the skill set – this is where WikiHouse really appealed. You can get involved without having trade skills.

“It is overwhelming to start with, feels like thousands of jigsaw pieces but then it starts to click into place you start feeling much more confident. Piece by piece you see your home start to take shape.”

Thanking all those who have helped, Beki added:

“Finding volunteers to help with the build has been surprisingly easy. Friends have been keen to lend a hand, and the Architecture Unknown team came with lots of friends. We even had some students from Lancaster University studying architecture came down and help us too.”

Charlie, who founded Architecture Unknown with Daniel Kelso in 2016, said:

“Beki and Alastair had a blank canvas and the opportunity to build their dream home. WikiHouse has allowed us to explore what they wanted from design and give them to confidence to take on the physical build themselves. Designing for such a beautiful setting, it feels good to put an eco-friendly, carbon neutral structure in this space – without limiting the spec or compromising on the finish of the build. It will make a remarkable home.”

Architecture Unknown are specialists in designing and building using WikiHouse to facilitate client’s ambitions through design and technical knowledge. The team can also provide training for any volunteers and onsite leadership to help during the build process in addition to their typical architectural duties.