As investors in the housebuilding and construction sectors, we are seeing a sea change in the urgency of tackling the carbon footprint in housing. Recent site visits to housebuilders Vistry and MJ Gleeson confirmed this is now translating to real changes on the ground, with newly specified innovations in technologies such as heat pump boilers and electric vehicle (EV) chargers set to become mainstream.

These changes are being driven by the government’s Future Homes standards, which will ensure all new homes built from 2025 will produce 75-80% less carbon emissions than those delivered under current regulations, with no new home built under the standards to be reliant on fossil fuels. There will be an emphasis on improved ventilation and reduced energy usage.

Prior to this, from June 2022, we will see new building regulations that target an initial 30% carbon reduction.

Under construction

According to Statista, residential housing accounts for around 15% of all UK greenhouse gas emissions. Engineering firm Arup, in conjunction with the Royal Institution of Chartered Surveyors, has calculated that more than 50% of the whole-life carbon emitted by a house occurs during the construction phase. This means the construction of new homes is of critical importance in limiting the environmental damage done by housing in the longer term.

By far the greatest challenge facing housebuilders trying to reduce their carbon footprint is the slow pace of change in the supply base. The infographic below analyses the carbon footprint of a typical new family home. It is worth noting how little is directly under the house builder’s control, with just 7% of the total emissions coming at a scope 1 or 2 level.

The dominant source of emissions comes from materials such as cement, bricks and tiling used in the construction of walls, roofs and foundations. The solutions to decarbonising such products are both complex and costly and remain several years away. Significant changes in the sourcing of energy supplies, in particular, present major challenges.

While there are government incentives to increase usage of materials such as timber, this remains a niche segment in the UK housing mix, despite strong take-up in regions such as North America.

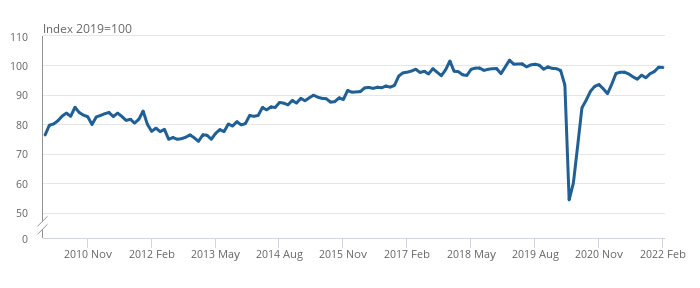

As with the demand for EVs, it is important to put the demand for new housing into context. Office for National Statistics data tells us there are around 28 million households in the UK, and this number has been growing at just under 1% per annum in recent years. The current level of new housing completions runs at around 250,000 per year, less than 1ͮ of the entire housing stock. This highlights the magnitude of the task in turning our homes green, both in terms of the technical and logistical challenges of retrofit and the significant costs for homeowners to do so.

The carbon footprint of a typical new family home

Social message

Current estimates for installing heat pump systems and EV chargers are in the region of £5,000-7,000 per home, which is a big pill for the average householder to swallow. While these costs will inevitably fall as production volumes increase, it does suggest we will need to see significant government intervention and subsidy for the 99% of the housing stock that is not new.

We know there is strong ongoing political support and funding for social housing, as the UK continues to face both housing shortages and affordability issues. At Amati, we are already investing in the theme of social housing, which will have the dual benefit of addressing net-zero targets while hopefully reducing the inequalities in housing. Our holdings in Vistry and MJ Gleeson play directly to such trends. For the homeowner looking to reduce their carbon footprint the message is clear. Be prepared to invest significantly in retrofitting your existing home or buy new and have it done for you.

Source: What Investment

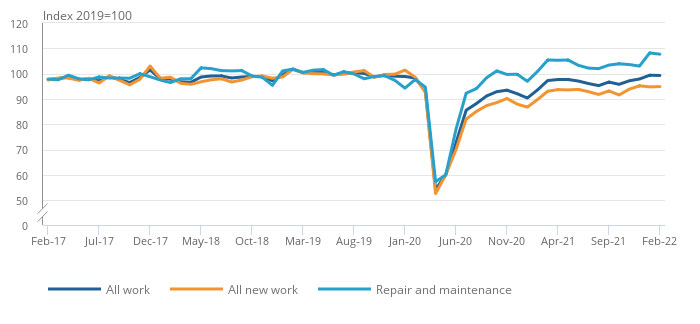

Public housing repair and maintenance was the only repair and maintenance sector to remain below its pre-coronavirus (COVID-19) level

Public housing repair and maintenance was the only repair and maintenance sector to remain below its pre-coronavirus (COVID-19) level