common sense, calm and commitment

Cp and hot water industry and this can be supported via gathered scientific data applied to finding solutions that allow for least harm and disruption to current standards of living and comfort.

The manufacturing sector of the heating and hot water industry has a responsibility in playing a leading role in the reduction and eventual removal of harmful emissions. For UK decarbonisation targets to be met, working practises that rely on fossil fuels have to be changed and transparent assessments of product impact and efficiency should be common currency. To enact the transition to greener energy there is a pressing need for unity of purpose across multiple industry sectors.

Rinnai Managing Director Tony Gittings says: “Fact, logic and reason must be employed to achieve the best outcome for all of us. We need decarbonisation, we need NetZero, and we need it as soon as possible but in such a way that is pragmatic in terms of catering to the existing populations and markets.”

“To further encourage decarbonisation the heating industry must look past just simple financial motivation. No one single product alone is presently capable of delivering NetZero, so rather than fracture into competing groups, the heating & hot water sector will benefit from a platform of cross-communication and information sharing that can be relayed to positively assist the UK end-user and customer.

“We need to look at this from the consumers’ viewpoint. We need to be putting accurate information in the public arena. At the moment there are a lot of interested bodies and companies showing understandable self-interest in wanting to know they have a future in the marketplace.

“In our sector we have manufacturers of similar or like-for-like products which are looking to what will replace natural gas as the fuel of mass consumption and how that will affect them. We also have the pragmatic logic of trying to find affordable fuels for the mass market. Alternatives on their own are simply not an answer. We also need to look at the range of innovations and developments such as Hydrogen and BioLPG that will come on stream.

“Yes, individual products have a place. But what would be the NetZero answer, as an example, to a commercial or industrial unit or site that has the added complications of needing Legionella prevention regimes and constant high temperature hot water in large volumes. How would electrification and heat pumps, for example, be attractive in terms of capital, installation and ongoing operational costs and performance?

“Everything has a role to play and everything non-carbon can have a future. And a collective, equable effort will give us the result we all want, the result we must have, if we are to have a sustained quality of life.

“We are a business based on engineering excellence and are employing technological creativity to achieve the targets. It will mean, in the UK, that we begin to offer a wider range of products under the H3 umbrella of Hydrogen, Heat Pumps and Hybrid Systems to enable our customers to achieve their own carbon reductions and eventual neutrality.”

Rinnai are also now offering a free “Carbon Cost Comparison” that can be found by following this LINK . The Rinnai Carbon Cost Comparison Form offers a free appraisal of a site’s current hot water delivery system, along with recommendations for reducing the carbon load.

Rinnai is a world leading manufacturer of hot water heaters producing over 2 million units a year. The company operates on each of the 5 continents and has an established reputation for products of high performance, robust cost efficiency and extended working lives.

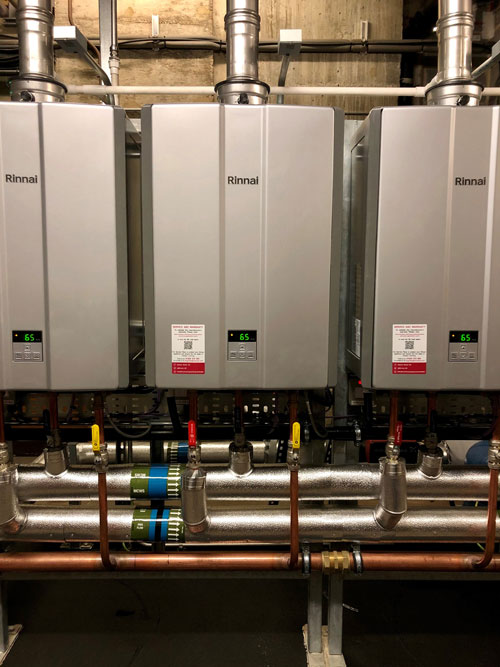

Rinnai hot water products offer a limitless supply of instantaneous temperature controlled hot water that can, at 65degrees C, act as a thermal disinfectant on all known bacteria.

Rinnai units are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours.

Rinnai is committed to decarbonisation and N series is hydrogen-blends ready NOW and can use BioLPG capable of delivering NetZero carbon emissions.

Rinnai offers comprehensive training courses and technical support in all aspects of the water heating industry. More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

For more information on the RINNAI product range visit

Says Chris Goggin, Operation Director for Rinnai, ’Our company operates on the five continents of the world producing over 2 million water heating units each year. We have a global reach of over 650 design engineers plus testing facilities in Japan, America and Australasia. We have moved this quickly as we perceive that the market is fast changing.

Says Chris Goggin, Operation Director for Rinnai, ’Our company operates on the five continents of the world producing over 2 million water heating units each year. We have a global reach of over 650 design engineers plus testing facilities in Japan, America and Australasia. We have moved this quickly as we perceive that the market is fast changing.