Designed for use within ventilated rainscreen facades and timber frame cladding systems, AIM Acoustic & Insulation Manufacturing’s Open State Cavity Barriers (OSCBs) allow free airflow and drainage and improve fire safety, providing a fire rating of up to two hours insulation and integrity in suitably supporting structures.

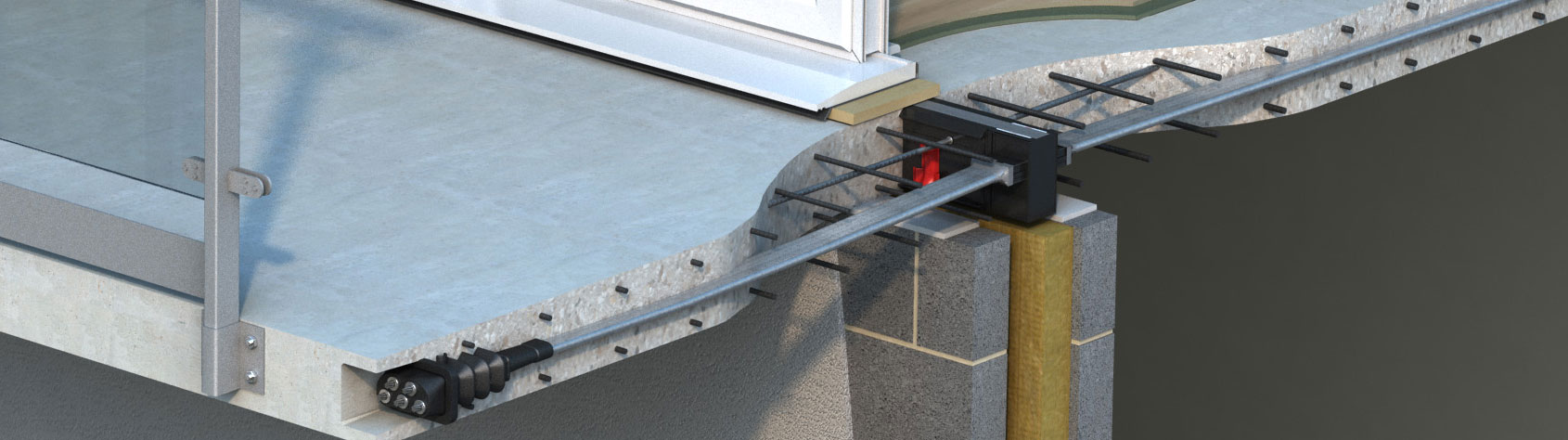

AIM’s OSCBs, when installed behind a façade system, allow the ventilation that is necessary to prevent problems with condensation and allows drainage, but, in the event of a fire, heat activates an intumescent strip which expands quickly to fully close the cavity.

Manufactured from high density Rockwool stone wool and faced with a higher performance intumescent strip, AIM’s range of four OSCBs provides either a 25mm or 44mm air gap and either a 60 or 120-minute rating for both integrity and insulation.

The OSCBs are an effective barrier to the passage of hot smoke and fire behind cladding systems for ventilated voids from 50mm up to 425mm in width. The OSCB 60/25 range can be used in cavities up to 600mm where the barrier is supported by Rockwool Duoslab insulation or equivalent.

The AIM range has been tested to TGD 19 and the general principles of BS EN 1363-1. They have been exposed to BS 8414 Fire performance of external cladding systems fire tests and assessed to BR135 to achieve pass results with a variety of third-party cladding systems. The AIM OSCB range has been tested in masonry constructions to establish the performance of the product itself and non-standard constructions representing site conditions.

The OSCBs tend to be used for horizontal fire stopping and permitting free flowing ventilation and drainage through the cavity in a vertical plain. AIM’s Wall Cavity Barriers provide a fully filled cavity solution and are generally used vertically to prevent the spread of fire across the face of a building. The two products can be combined to provide an overall fire stopping solution. Vertical open state barrier options are also available.

Supplied pre-cut in 1000mm lengths, 90mm thick with widths varying according to the void size, the OSCBs come made to order to the requirements of the project being constructed. Lead times are very good at, typically, seven to ten working days, often less than this. AIM OSCB’s are supplied with the required fixing clips. Installation is quick and cost effective, the AIM OSCBs are easy to install with a simple fixing procedure. No specialist tools are required.

CLICK HERE to download AIM’s

OSCB technical literature and fixing instructions

UK-based AIM Acoustic & Insulation Manufacturing has over 30 years-experience in the design, testing and manufacturing of high-quality fire, thermal and acoustic barriers.

The company produces a wide variety of bespoke insulation products to customer specification and a range of standard fire, thermal and acoustic insulation products. AIM’s Technical & Development team is available to provide customers with expert support covering specification, development, manufacture and installation.

The new Tyneham heat pump range from Hamworthy offers superb operational reliability, excellent quality, and outstanding performance. One of the smallest commercial heat pumps on the market, the new product offering from Hamworthy Heating features a co-efficiency of performance (COP) rating of up to 4.85, to provide efficient, low carbon heating.

The new Tyneham heat pump range from Hamworthy offers superb operational reliability, excellent quality, and outstanding performance. One of the smallest commercial heat pumps on the market, the new product offering from Hamworthy Heating features a co-efficiency of performance (COP) rating of up to 4.85, to provide efficient, low carbon heating.