OFFSITE CONSTRUCTION – INNOVATION IN PRACTICE

Productivity, collaboration, innovation and skills are the cornerstones of the government’s most recent construction strategy, published in March this year, and still reflects the 2013 joint approach from government and industry. The Construction 2025 ambition focuses on erecting buildings that create less emissions, can be delivered quickly and cost less to build and run over their lifetime.

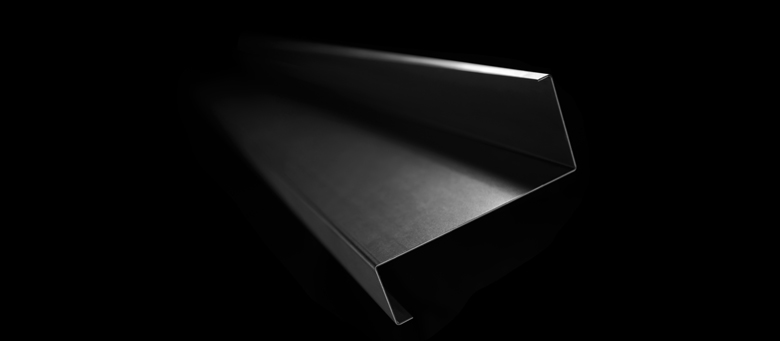

One company that shares the Construction 2025 vision is voestalpine Metsec plc. Located in the heart of the industrial West Midlands, it is the first cold roll forming company to be certified BIM Level 2 for design and manufacture by the BSI – a key element of the national strategy.

One company that shares the Construction 2025 vision is voestalpine Metsec plc. Located in the heart of the industrial West Midlands, it is the first cold roll forming company to be certified BIM Level 2 for design and manufacture by the BSI – a key element of the national strategy.

BIM Level 2 improves accuracy, efficiency, and productivity, resulting in time and cost savings. Ryan Simmonds, Sales Director for Metsec Framing explains:

“BIM has really changed the way we approach building design – it’s a crucial design tool to ensure the client receives the best performance quality and value for money. With buildings becoming more complex, planning drawings simply don’t provide enough information and manufacturers must always be at the table in the early stages to get the best long-term response.”

The modern construction market is not just about BIM but also methods of construction which enable cost, waste and time savings. Once again, Metsec is at the forefront of innovation when it comes to offsite construction methods – its first Metframe building was completed in Norfolk in 1984.

Thirty years on, Metframe is now a well-established solution to provide the load bearing structure for low to medium rise structures certified for up to 15 storeys in height, with scope for flexibility in design, making it ideal for residential, hotels, social housing or student accommodation.

Metframe structures can incorporate steel joisted or concrete floors, depending on the client’s requirements. Joisted floors offer a much lighter structure, but concrete floors generally provide a higher level of acoustic and fire protection. Pitched, dormer or flat roofs can be readily incorporated into the system as well as balconies, cantilevers and insets.

As well as flexible design, the Metframe system scores highly on cost saving when compared against timber and volumetric construction and there is no compromise on quality. Cost savings are also achieved through the speed of build that the system allows, with Metframe structures regularly taking less than two weeks per floor to construct. Coupled with the energy efficiency and zero waste offered by these buildings, it is not surprising to see so many high profile developments adopting the Metframe system.

Genting UK turned to Metframe for the construction of its £150m Resorts World development in Birmingham. Built by main contractor Galliford Try, the unique 55,000sqm leisure and entertainment complex boasts a hotel, spa, casino, 50 retail outlets, a wide range of restaurants and bars and a multi-screen IMAX cinema.

Metframe was chosen as the structural solution to enable quick and efficient construction of the top three storeys of the complex. The three-storey structure forms a 178-room, four-star boutique hotel and spa facility with five-star suites on the top floor, which caters for delegates and visitors to the 900 events that are held at the National Exhibition Centre annually as well as leisure guests visiting the West Midlands region.

As Metframe is assembled offsite to form easy-to-erect panels, the full frame could be delivered to the contractor in the required erection sequence and simply bolted together on-site.

Steve Milward, Design Manager at Galliford Try explains the benefits of using Metframe for the Resorts World project: “Due to the lightweight nature of the joisted floor solution within the Metframe system, Metsec was able to deliver a frame that fitted within the strict criteria of the supporting structure below. Also, a huge benefit for the project was the speed of installation. By using Metframe, we could easily manage the build in phases to ensure structural soundness throughout the process.”

Thomas Atkin of Atkin Trade Specialists, who installed the Metframe system, comments: “In total, the construction of all 178 units took just 16 weeks, which is highly impressive for a build this big. Metsec worked closely with us to produce a 3D design of the hotel structure for Galliford Try, which enabled us to plan the works and stick to the contractor’s construction programme.”

Richard Allen, Marketing and Business Development Director at Metsec added: “As a Black Country-based business, we are incredibly proud that we were able to supply a cost-effective and highly manageable solution for the landmark project at the NEC. Metframe is an extremely competitive solution, which delivers a high quality building. Therefore, it was the perfect choice for the construction of the new 4-star boutique hotel at the Resorts World complex.”

Leave a Reply

Want to join the discussion?Feel free to contribute!