LAUNCH OF WORLD’S FIRST SOLUTION FOR POST TENSIONED BALCONY CONNECTORS

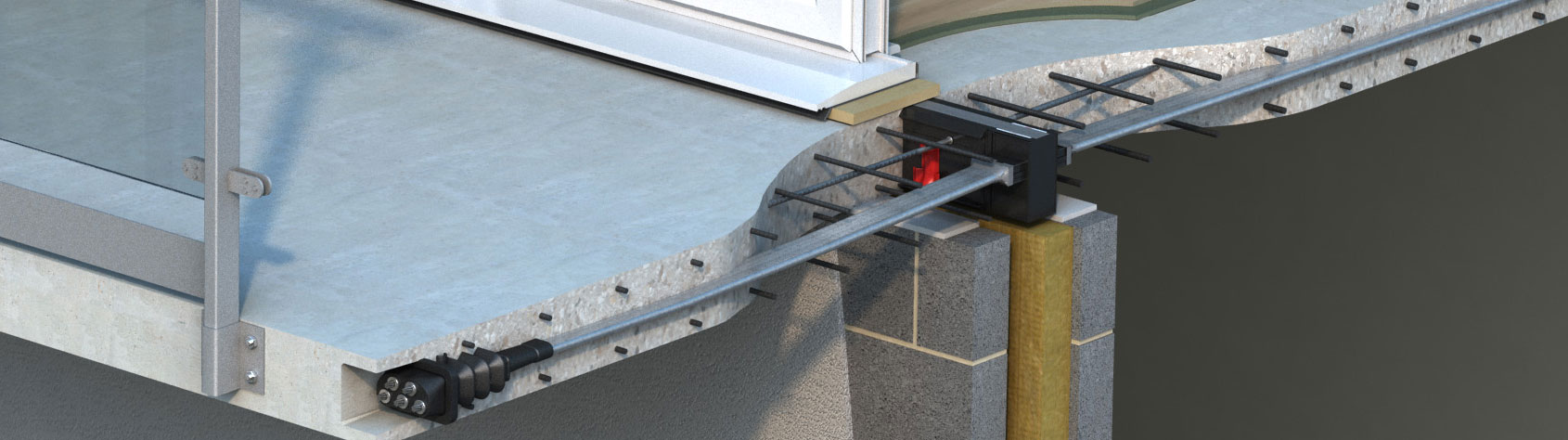

Leading global lifting, connecting and anchoring company Leviat has launched the world’s first insulated balcony connector element for post tensioning applications, which can be used alongside its industry renowned range of Halfen HIT Structural Thermal Breaks.

Hervé Poveda, Leviat’s Head of Product Excellence, Reinforcement & Building Physics – Europe & APAC, said: “The development of this innovative solution was as a result of our customers looking to include balconies in the post tensioning process. Our new Halfen HIT Insulated Balcony Connector System allows balconies to be cast together with the main slab and then simultaneously stressed – something which has never been possible before with conventionally reinforced concrete balconies. Furthermore, formwork installation and removal on balconies and the main slab can take place all at the same time, driving significant efficiencies on construction sites, enabling users to build better and faster which reduces costs.”

Post tensioning performed on-site in cast-in-place applications gives designers flexibility, allowing them to create original concrete components that are thinner, longer and stronger. Architects can take full advantage of the plasticity of concrete in their designs to create truly amazing spaces.

Our range of balcony connectors provide continuity to both the concrete reinforcement and the thermal insulation of the building envelope, protecting against the effects of cold bridging, eliminating the risk of condensation and mould growth, and guaranteeing the comfort of the building’s occupants.

Specifiers can be confident that the new Halfen HIT Insulated Balcony Connector system complies with the UK’s latest guidance and building regulations, with particular reference to fire resistance. The innovative Halfen HIT Transition Piece is filled with mineral wool insulation for optimum thermal efficiency and fire resistance. The mineral wool specification is identical to that used for standard HIT insulated connection elements, which have an REI 120 fire resistance rating.

The Halfen HIT Insulated Connection system has recently been granted a UKTA by the British Board of Agrément, covering compressive design resistance as required for post tensioning applications. Halfen HIT Transition Pieces are designed for use with all types and configurations of post tensioning cables currently available on the market, using either bonded or unbonded strands.

When using Halfen HIT Transition Pieces, HIT-HP and HIT-SP, post tensioning cables can run directly through the structural thermal break at the interface between the balcony and supporting slab, enabling stressing to take place at the edge of the balcony rather than at the thermal break location; this considerably relieves reinforcement congestion and speeds up the installation process.

Leviat have developed a robust, Eurocode-compliant design methodology for the use of Halfen HIT Insulated Balcony Connector elements, and can provide suitable guidance to specifiers on the most efficient connector layouts, taking into consideration the position of post tensioning cables.

Post tensioning strengthens concrete by exploiting its strength when in compression and helping to overcome its inherent weakness in resisting tension. As a critical structural component, our balcony connectors transfer tension and compression forces in addition to bending moments and shear forces, maintaining structural integrity and minimising heat loss at balcony locations.

Nicolas De Vrieze, Leviat’s Product Manager for Structural Thermal Breaks & Acoustics – Europe & APAC, said: “We are delighted to be able to bring this engineered solution to the market. Its development in response to customer requirements demonstrates that we listen and we respond, manufacturing innovative connecting technology fit for the future.”

Patents for this solution have been applied for in Europe and the United States.

Leviat, a CRH company, is a global leader in connecting, fixing, lifting and anchoring technology for the construction industry. Leviat’s engineered products and innovative construction solutions are used in a variety of market segments, from residential to infrastructure, enabling users to build better, stronger, safer and faster. The company employs 3,000 people at 60 locations in North America, Europe, Asia and Australasia. Leviat’s suite of trusted product brands include Ancon, HALFEN, Plaka and Meadow Burke.

For more information CLICK HERE

Leave a Reply

Want to join the discussion?Feel free to contribute!