The Challenging Elizabethan Line

Today’s the day: after some 13 years of construction Crossrail’s Elizabeth line will finally open.

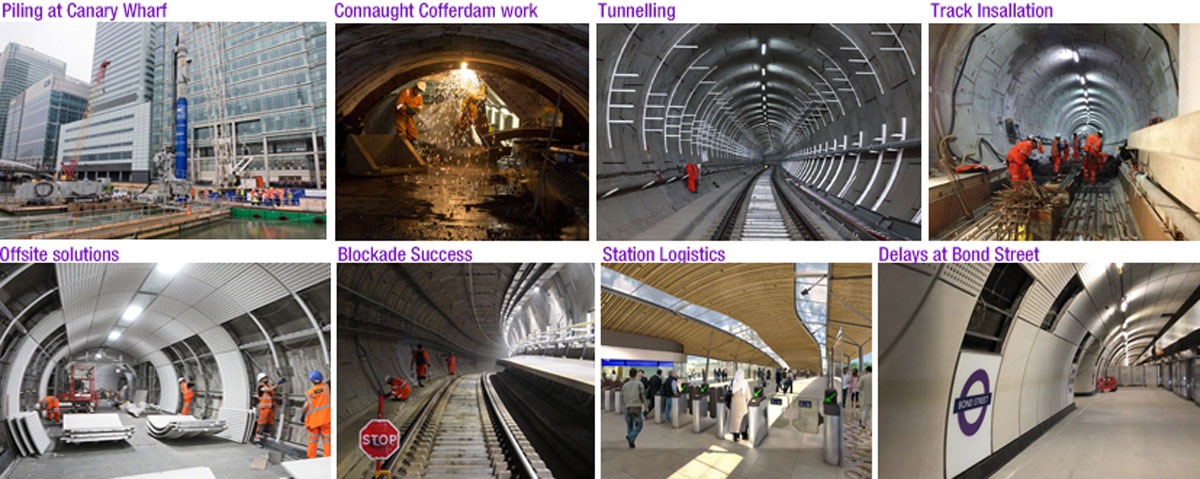

The Crossrail project first broke ground in May 2009, with the launch of the first pile at the site of the new Canary Wharf station. Tunnelling began in May 2012 and more recent years have seen the project’s stations completed and a move to operational testing.

So what have been some of the biggest engineering challenges and triumphs during construction?

Piling at Canary Wharf

One of the project’s first tasks in back in 2009 was creating the station box at Canary Wharf − a 256m long, 30m wide, six storey deep structure rising out of the water from the below the river bed.

Canary Wharf Contractors dewatered the lower aquifer around the site to create a drier underground environment to speed piling by two or three times. Building this tied cantilever cofferdam required some heavy duty piling.

Two Giken silent piling rigs worked eastwards and westwards away from one another above the water along the north side of the box, rotating 1.2m diameter tubular steel piles down to 18.5m into the dock bed. Canary Wharf Contractors says this is the first time this machinery has done this kind of piling in the UK.

Construction work on the station box was completed in March 2012, five months ahead of schedule.

Connaught Cofferdam work

Reconstruction of the Victorian Connaught Tunnel for reuse by Crossrail was also completed ahead of schedule in September 2013.

Cofferdams that were installed in the dock to allow access to the crown of the tunnel were removed in time for the dock to be used to allow ships to access the Excel exhibition centre for a bi-annual defence show.

Tunnelling

Tunnelling work completed in June 2015, with Crossrail releasing drone footage of the completed tunnels for the railway.

Eight Herrenknecht tunnel boring machines (TBMs) bored 42km of 6.2m-diameter rail tunnels under London. Another 13.5km of new passenger, platform and service tunnels were constructed within the new Crossrail stations using sprayed concrete lining.

Six of the TBMs were earth pressure balance tunnelling machines weighing 980t and measuring 148m in length. They were employed to dig through the London clays, sands and gravels that prevail beneath the capital.

Two 110m mixed-shield slurry machines (Mary and Sophia) tunnelled through the wet chalk and flint beneath the River Thames for the section between North Woolwich and the Plumstead portal in south east London.

In total, the tunnels are lined with over 220,000 concrete segments weighing 3.4t each. In each section, seven segments and a key stone slot together to form a completed tunnel ring.

Improvements to TBM technology – including real-time settlement control at the cutting faces – gave Crossrail the confidence to set maximum face loss limits as low as 0.5% to ensure the impact on the surface would be acceptable.

Track installation

The permanent track for the Elizabeth line was officially completed in September 2017.

The final piece of track was laid 35m below in the eastbound tunnel of the new Whitechapel Elizabeth line station. Track quality control engineer Ellen McGuinness affixed the final rail clips to the track.

Offsite solutions for Liverpool Street station

Threaded into the urban fabric of the City of London, Liverpool Street Elizabeth line station provided unique challenges to the teams working on its construction.

Built by Laing O’Rourke, the station was transferred to Transport for London (TfL) in July 2021.

At 34m below ground at platform level, Liverpool Street is the deepest of the new central London stations and has a total of 15 escalators and seven lifts.

A maze of sewers, existing Tube lines and the Post Office Railway had to be navigated for the station, while nearly 4,000 skeletons from the Bedlam burial site and thousands of artefacts dating back to Roman times were also discovered.

Work was running six months behind schedule due to tunnelling delays, but the Laing O’Rourke team were able to recover this time using offsite solutions and a design for manufacture and assembly (DfMA) approach. This enabled 17 months’ programme activity to be completed in 11 months.

The grooved and angled ceilings in both ticket halls, for example, were formed from pre-cast panels, manufactured at Laing O’Rourke’s Centre of Excellence for Modern Construction in Nottinghamshire.

Blockade success

Crossrail completed 96% of all tasks scheduled for its six week blockade in 2020.

It was put in place to help recover some of the time lost due to Covid-19, lockdown and subsequent working restrictions such as social distancing.

In total 1,235 of a total 1,286 milestones were completed, according to Crossrail data shared with NCE.

Works completed during the construction blockade included:

- 58 Tunnel Ladders installed

- 28 Bent Bolt OHLE replacements

- 27 LV Power corrections

- 15 Platform Screen Door Air Gaps

- 8 Cross Passage Leaks completed

Whitechapel station logistics

Contractors charged with delivering Crossrail’s Whitechapel station revealed the complex challenges they had to overcome.

TfL took control of the station following the completion of work by a joint venture between Balfour Beatty, Morgan Sindall and Vinci (BBMV).

In a video released by BBMV, the project’s section manager Rob Langford emphasised the logistical complexity of constructing the station.

In particular, Langford pointed to the logistical challenge of working above an operational railway while delivering the station.

Delays at Bond Street station

Despite months of reassurances that Bond Street station was”catching up fast” with the rest of the Crossrail project, in February it was confirmed that the problem-hit station would not open with the rest of the Elizabeth line.

It is a mined station, 28m below ground with platforms of up to 255m. Two new ticket halls at street level – one at Davies Street, the other at Hanover Square – will lead passengers to the platforms.

The station has long been identified as a problem point for the project, with chief executive Mark Wild admitting in May 2019 that it would be likely to open at a different time to the rest of the line. Wild said tunnelling problems on the Bond Street project dating back to 2014 were behind the delay.

Completing civils works at the station delayed mechanical and electrical equipment installation by about a year, and delays to the installation of two large tunnel ventilation fans set work further back.

Then, of course, came Crossrail Ltd’s parting of ways with the station’s main contractor Costain Skanska JV (CSJV). In June 2020, Crossrail Ltd announced that CSJV would no longer work on the job, with NCE later revealing that the contractor was paid £19M to close out the contract.

Wild later explained that CSJV was taken off the Bond Street job because of the impact of the Covid-19 pandemic.

Source: New Civil Engineer

Leave a Reply

Want to join the discussion?Feel free to contribute!