Significant investment in product development and testing for its Open State Cavity Barrier (OSCB) and new Wall Cavity Barrier (Red Edition) ranges has enhanced their suitability for rainscreen cladding systems, says AIM – Acoustic & Insulation Manufacturing.

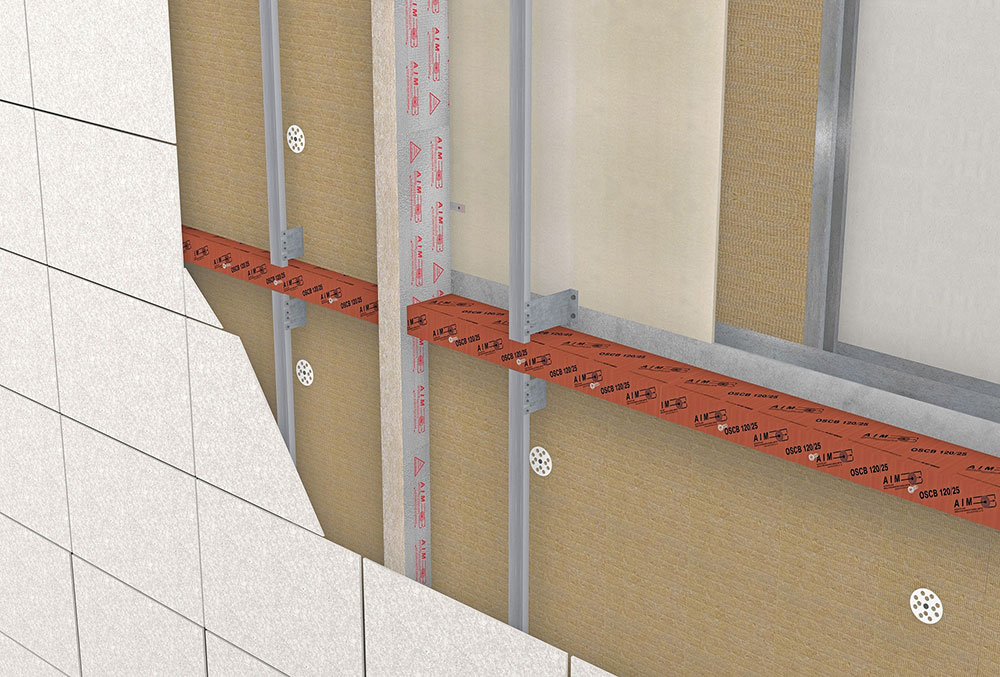

Open state cavity barriers and full fill cavity barriers are crucial to fire safety within rainscreen cladding on medium and high-rise buildings. Together they can achieve compartmentation within the void created by the rainscreen cladding. This then provides an effective barrier to the passage of hot smoke and fire behind the cladding system. The OSCB is installed horizontally to permit free flowing ventilation through the cavity in a vertical plane and the wall cavity barrier is fitted vertically to complete compartment lines.

AIM’s six OSCBs allow the ventilation necessary within the wall construction to prevent problems of condensation allowing free airflow and drainage with either a 25mm or 44mm air gap. They can fill voids up to 425mm (or greater in particular circumstances). In the event of a fire, heat activates the OSCBs intumescent strip which expands quickly to close the cavity fully. They offer either a 60, 90 or 120-minute performance for both integrity and insulation confirmed by testing in accordance with ASFP Technical Guidance Document 19 and to the general principles of BS EN 1363-1:2020.

For use in cavity voids up to 600mm AIM’s new Wall Cavity Barrier (Red Edition) range is available cut to size or in slab form. Available in three thicknesses, 75mm, 100mm and 125mm, they prevent the passage of heat, flame and smoke within the cavity for 30, 60 or 120-minute fire rating periods tested to BS EN 1366-4:2021. This rating makes these wall cavity barriers suitable for medium to high rise buildings.

Both the AIM OSCB and Wall Cavity Barrier (Red Edition) products have third party certification issued by IFC Certification Ltd.

“The wide scope of test evidence we now have for the use of our OSCB and Wall Cavity Barrier (Red Edition) ranges gives us a compelling fire barrier package for rainscreen cladding,” explains Ian Exall, AIM’s commercial director.

“With new technical literature covering the use of these two products together to achieve compartmentation in external cladding, we aim to make specification and installation more straightforward for specifiers, system providers and installers.”

“We look forward to making further product development and testing announcements during the next few months.”

AIM’s OSCBs and Wall Cavity Barrier (Red Edition) ranges are suitable for both new build rainscreen projects and remediation work.

AIM provides technical, specification, training and on-site support. New Wall Cavity Barrier (Red Edition) and OSCB technical literature can be downloaded at from this LINK