Rinnai UK’s Operations Director Chris Goggin explains what synthetic gasses are being developed and produced as a possible replacement to natural gas. Further information of production methods will be considered when evaluating the practical and technical feasibility of introducing synthetic gasses into UK and international energy infrastructure.

Since the 1970s when North Sea gas fields were located, the UK had, until recently, become reliant on fossil fuels. To distribute gas into domiciles and commercial premises 176,000 miles of pipeline infrastructure has been installed across the UK. This subterranean energy distribution network provides 40% of total energy consumption in the form of natural gas. Eighty-five percent of UK buildings use natural gas for property heating and hot water. Natural gas is still the prominent domestic and commercial power option.

In terms of societal behaviour and infrastructure the UK is well prepared for any move away from natural gas towards an alternative gaseous fuel that fulfils operational and ecological requirements. What synthetic and ulterior gasses could replace fossil fuels?

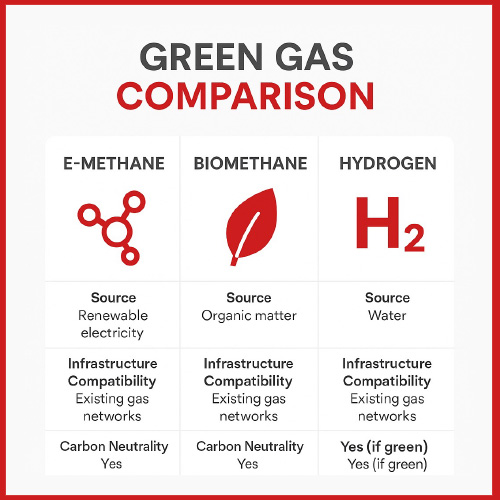

Work that identifies potential future gasses has revealed a number of candidates capable of UK infrastructure compatibility. A low carbon gas that can be accepted by present pipelines and behave in a similar, if not identical, manner to fossil fuels is the ideal replacement.

Amongst the list of potential replacements are e-methane and biomethane. E-methane is the abbreviated name given to synthetic methane or renewable methane, a gas which is created by extracting captured carbon dioxide and then blended with green hydrogen, itself produced via renewable energy. Green hydrogen electricity is converted into a storable low carbon gas – e-methane.

Biomethane is produced in a separate process – methane is captured from natural biological waste and forms during a natural process called ‘anaerobic digestion.’ In the absence of oxygen, microorganisms will begin to break down matter yielding a gas – methane. Once impurities are removed the methane gas becomes upgraded and biomethane is created.

Both biomethane and e-methane are capable of identical operating behaviour when compared to fossil fuels and can therefore be placed into existing infrastructure. Biomethane and e-methane can immediately fulfil the role of fossil fuels without any fracture towards appliance operating efficiency, commercial activity, or societal cohesion.

Synthetic natural gas (SNG) is an umbrella term for a variety of gasses that behave and perform very similarly to natural gas. SNG can be produced either using biomass or renewable power. Any gas that is generated via biomass or renewable energy is referred to as Biogas, e-gas, and syngas.

If a gas is created using waste such as manure, the gasification process of production is known as biochemical SNG production. If the process of gas manufacturing involves hydrogen that is renewably produced, then that (SNG) gas derives from a production concept named Power-to-Gas or Power-to-X. These ingredients and production approaches birth end-product e-gas/syngas.

Syngas is potentially interchangeable with any appliance that has previously accepted natural gas. Liquified or compressed Syngas can also be potentially transported through any functioning gas grid for usage or export and can be stored in the exact same environment as natural gas for identical durations of time.

Raw materials required for the creation of syngas arrive in the form of either fossil fuels or bio-waste. These materials are used to create a feedstock which is then inserted into a gasifier in either dry or slurry form. Once inside a gasifier that is low on oxygen the feedstock reacts with steam at a high pressure and temperature. This process creates syngas that is comprised of carbon monoxide, hydrogen and lesser amounts of methane and carbon dioxide.

Although UK public and political confidence in hydrogen requires upholstering, many global economies feel more optimistic in adopting domestic and commercial hydrogen usage. Swedish industrial decarbonising company Stegra has now secured funding of close to €6.5 billion to construct a large-scale green steel plant in Northern Sweden. The new installation will use green hydrogen when manufacturing end-product steel.

Additionally, the UK government very recently has announced that £500 million of funding will be provided towards new hydrogen infrastructure projects. This funding will stimulate regional hydrogen usage in transport, as well as storage networks that link hydrogen manufacturers, industrial end-users, and power stations.

Once the UK likely eradicates fossil fuels from the domestic energy mix a substitute gas will have to be introduced to provide domestic and commercial premises with heat as well as hot water in areas that are economically, practically and technically difficult to electrify.

Practical decision making would prefer a decarbonising substitute gas that can fit seamlessly into the UK gas grid without additional cost. All gasses in this article fit within this remit. The task is to identify one outstanding candidate that is accepted by all energy market fronts – customers, environmental lobbies, and politics.

Rinnai will continue to offer information on potential energies that the UK could adopt soon. Rinnai believes balanced coverage on legislative detail that affects customer fuel options and costs can positively influence UK customer purchasing decision making.

RINNAI’S H3 DECARBONISATION OFFERS PATHWAYS & CUSTOMER COST REDUCTIONS

FOR COMMERCIAL, DOMESTIC AND OFF-GRID HEATING & HOT WATER DELIVERY

www.rinnai-uk.co.uk/about us/H3

Rinnai’s H3 range of decarbonising products include hydrogen / BioLPG ready technology, hybrid systems, and a wide range of LOW GWP heat pumps and solar thermal. Also, within Rinnai’s H3 range is Infinity hydrogen blend ready and BioLPG ready continuous flow water heaters which are stacked with a multitude of features that ensure long life, robust & durable use, customer satisfaction and product efficiency.

Rinnai’s range of decarbonising products – H1/H2/H3 – consists of heat pump, solar, hydrogen in any configuration, hybrid formats for either residential or commercial applications. Rinnai’s H3 range of products offer contractors, consultants and end users a range of efficient, robust and affordable decarbonising appliances which create practical, economic and technically feasible solutions. The range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters.

Rinnai H1 continuous water heaters and boilers offer practical and economic decarbonization delivered through technological innovation in hydrogen and renewable liquid gas ready technology.

Rinnai’s H1 option is centred on hydrogen, as it is anticipated that clean hydrogen fuels will become internationally energy market-relevant in the future; Rinnai water heaters are hydrogen 20% blends ready and include the world’s first 100% hydrogen-ready hot water heating technology.

Rinnai H2 – Decarbonization simplified with renewable gas-ready units, Solar Thermal and Heat Pump Hybrids. Rinnai H2 is designed to introduce a practical and low-cost option which may suit specific sites and enable multiple decarbonisation pathways with the addition of high performance.

Rinnai H3 – Low-GWP heat pump technology made easy – Rinnai heat pumps are available for domestic and commercial usage with an extensive range of 4 – 115kW appliances.

Rinnai’s H3 heat pumps utilise R32 refrigerant and have favourable COP and SCOP.

Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

Rinnai’s commercial and domestic continuous flow water heaters offer a limitless supply of instantaneous temperature controlled hot water and all units are designed to align with present and future energy sources. Rinnai condensing water heaters accept either existing fuel or hydrogen gas blends. Rinnai units are also suited for off-grid customers who require LPG and BioLPG or DME.

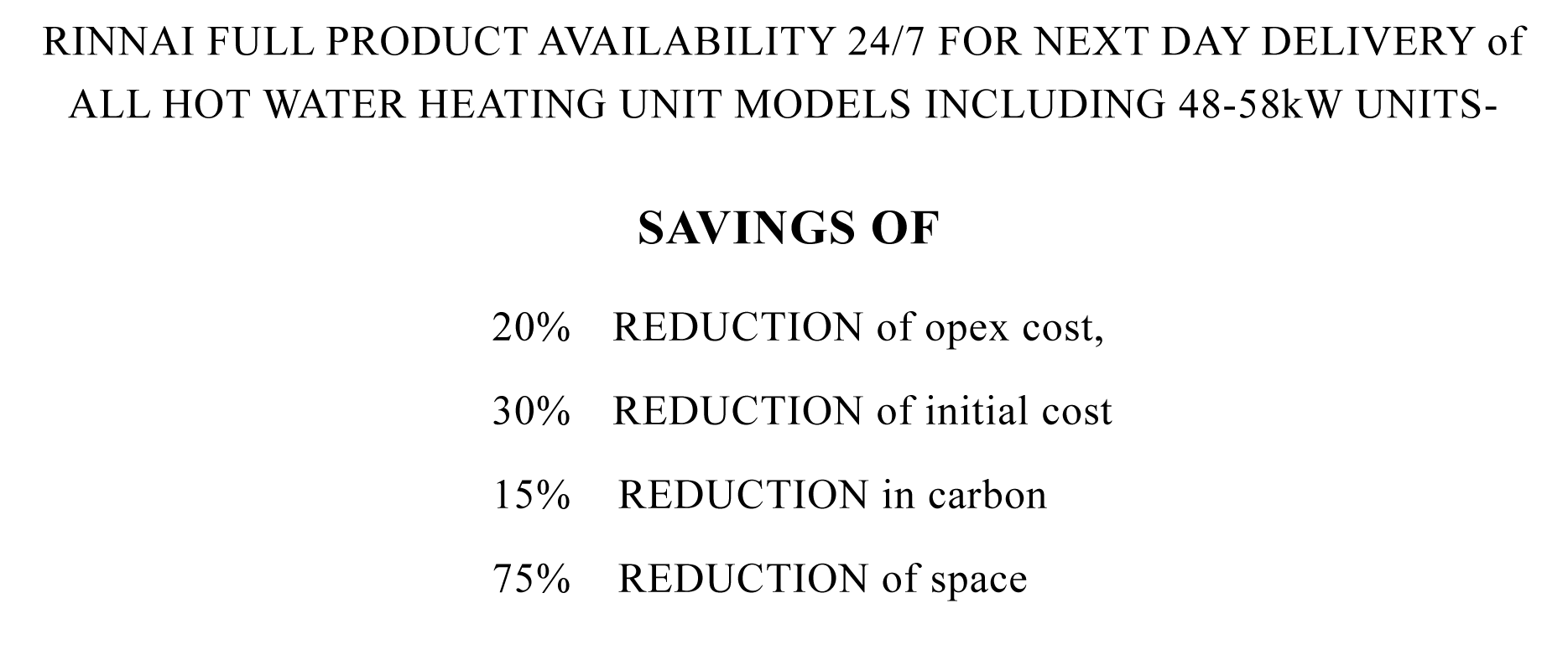

Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours. Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question. Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s.

CLICK HERE TO VISIT THE RINNAI WEBSITE

or HERE to EMAIL RINNAI

CLICK HERE For more information on the RINNAI product range