A Gloucestershire non-league football club is aiming to decarbonise the whole of its ablutions by installing a high temperature R290 heat pump solution for the DHW requirements in the club’s washrooms and showers. The target for the football club is to reduce carbon by installing a state-of-the-art Rinnai commercial heat pump system.

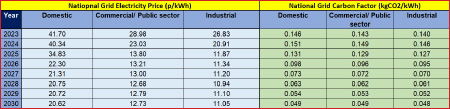

Rinnai produced full data modelling for the site, that focuses on capital and operational costs whilst also reviewing the carbon intensity of different hybrid and heat pump systems so that all the costs and performance parameters where completely visualized for the client. This transparency is critical to users, who can now be made aware of the full costs associated with electrical systems. The operational costs are modelled against the projected cost reductions in electricity prices from valid sources. A breakdown of fuel costs is provided below.

Figure 2: Energy prices and carbon factors used for analysis study.

Figure 3: Energy prices and carbon factors used for analysis study.

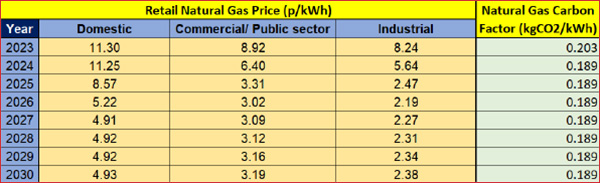

When comparing OPEX, CAPEX and carbon reductions information pertaining to the current system is not available, however it is known that the football club uses a gas-powered system. Therefore, a comparison between a Rinnai Heat Pump and Rinnai natural gas powered N1300 can be made and illustrated with visual graphs.

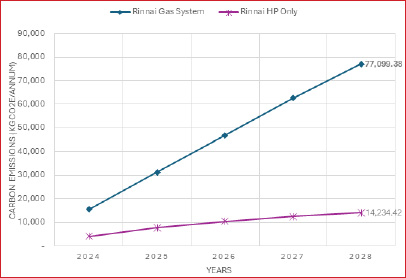

The first graph will detail the amount of carbon reductions made possible through installing a Rinnai high temperature heat pump when compared to a natural gas powered N1300. Rinnai’s gas system is represented in blue whilst Rinnai’s High Temperature Heat Pump is highlighted in purple.

Figure 4: Carbon Emissions Lifecycle comparing a H1 and a H3 system for DHW

The above graph demonstrates the carbon reductions achieved through a Rinnai high temperature heat pump. Over five years a gas fired system will emit over 5 times the amount of carbon emissions when compared to a Rinnai heat pump. Overall, there is an 81% reduction in carbon offshoots over 5 years.

Below is another graph that details the cumulative running costs over a 5-year period. The OPEX costs are compared to a Rinnai N1300 natural gas appliance.

Figure 5: Cumulative Running Costs (OPEX) comparing a H1 and a H3 system for DHW

The above graph illustrates the difference in cost between a Rinnai N1300 (blue) and a High Temperature Heat Pump (purple). Over a 5-year period there is a 23% increase in operational costs. A Rinnai natural gas system will cost £18,844.71, whilst a Rinnai High Temperature Heat Pump would cost £24,296.58.

Rinnai will continue to provide transparent examples of carbon reducing technology that results in cleaner local air quality. Rinnai’s product offering includes multiple technologies that are capable of being powered by current and future clean energies. All commercial operations and premises that require a reduction in emissions should consider manufacturers that can offer a selection of appliances capable of accepting various clean and current fuels.

To take advantage of the Rinnai design and modelling support service CLICK HERE

or call us today on 0300 373 0660

![]()

RINNAI OFFERS CLEAR PATHWAYS TO LOWER CARBON AND DECARBONISATION PLUS CUSTOMER COST REDUCTIONS FOR COMMERCIAL, DOMESTIC AND OFF-GRID HEATING & HOT WATER DELIVERY

- Rinnai’s range of decarbonising products – H1/H2/H3 – consists of hot water heating units in gas/BioLPG/DME, hydrogen ready units, electric instantaneous hot water heaters, electric storage cylinders and buffer vessels, a comprehensive range of heat pumps, solar, hydrogen-ready or natural gas in any configuration of hybrid formats for either residential or commercial applications. Rinnai’s H1/2/3 range of products and systems offer contractors, consultants and end users a range of efficient, robust and affordable low carbon/decarbonising appliances which create practical, economic and technically feasible solutions.

- Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

- Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours.

- Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question.

- Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s.

- The Rinnai range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

RINNAI FULL PRODUCT AVAILABILITY 24/7 FOR NEXT DAY DELIVERY of

ALL HOT WATER HEATING UNIT MODELS INCLUDING 48-58kW UNITS-

SAVINGS OF

20% REDUCTION of opex cost

30% REDUCTION of initial cost

15% REDUCTION in carbon

75% REDUCTION of space