Rinnai has provided a low carbon DHW (domestic hot water) Heat Pump solution, with Seasonal Performance Factors (SPF) Analysis, for a Northwest call center to upgrade its existing system to meet government guidance on carbon reduction. The existing hot water system was 2 x 20kW water heaters, each with 300L of hot water storage, and was working at an efficiency level of just 77%.

Gathered hot water usage data suggests a peak hot water usage of approximately 542L and a recovery period of less than 1 hour. Based on this information the Rinnai Technical Design Team were able to examine two options suited to the site.

- H2 Hybrid Electric System: 3x 9kW R290 Heat Pumps + 1x 300L Heat Pump Storage + 1x 215L Electric Cylinder with 2x 9kW immersion ports

- H3 Heat Pump System: 4x 9kW R290 Heat Pumps + 1x 500L Heat Pump Storage.

Because the site only had single phase power, Rinnai opted for multiple 9kW R290 heat pumps rather than one larger R290 commercial air-source heat pump, and the new Heat Pump-based system will now supply all the hot water to all call center staff using sinks, showers and wash hand basins.

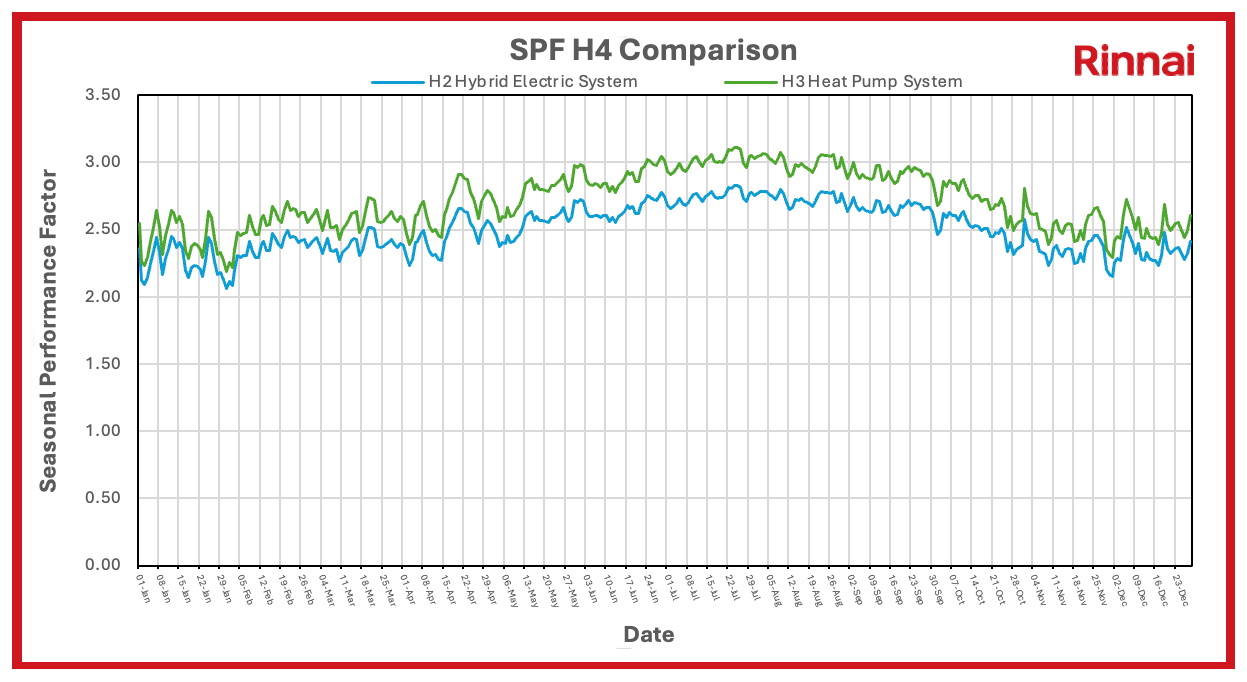

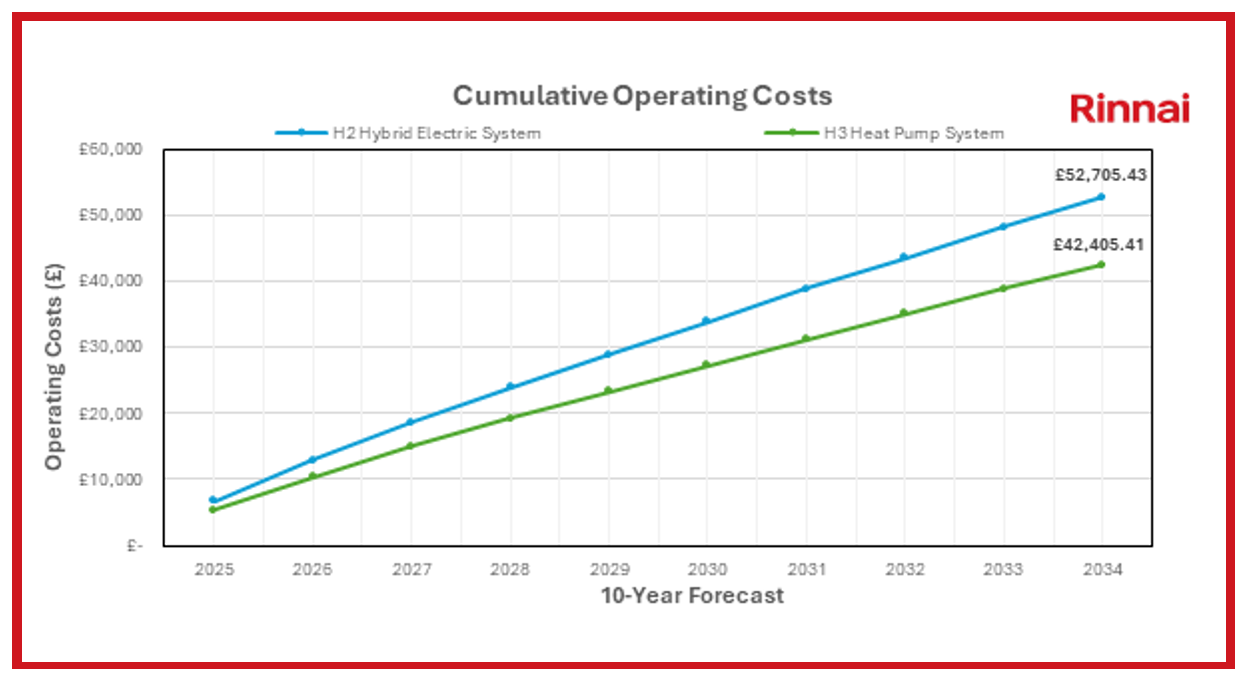

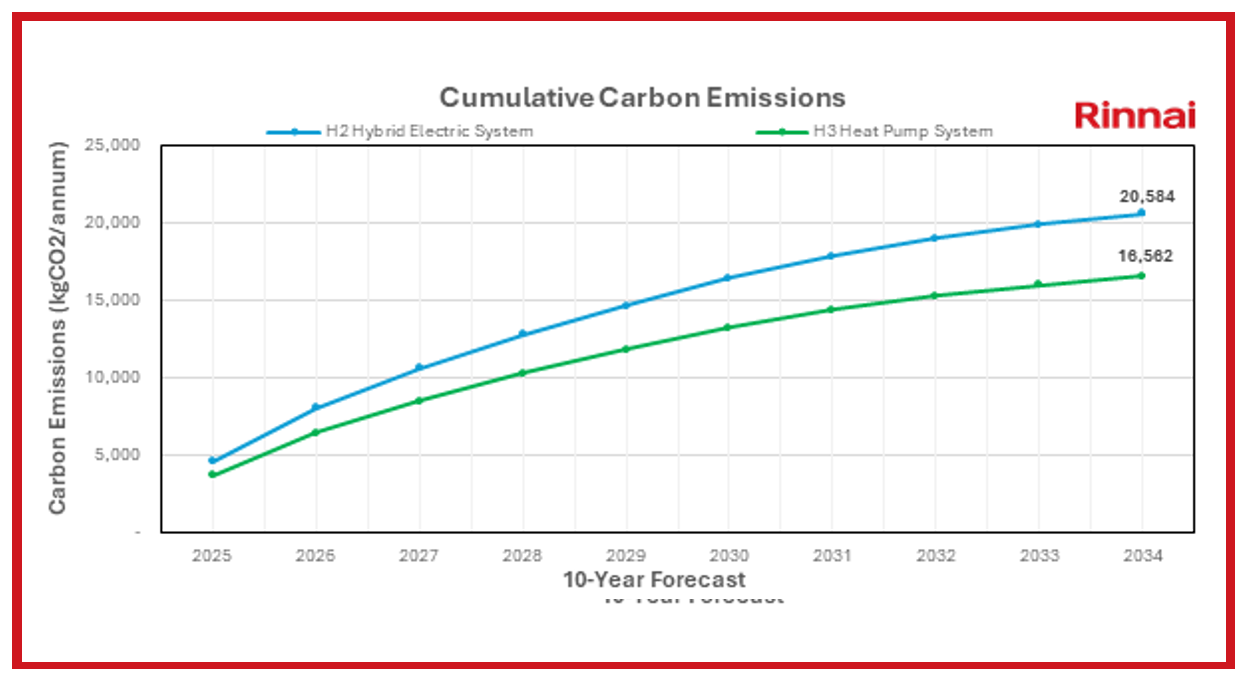

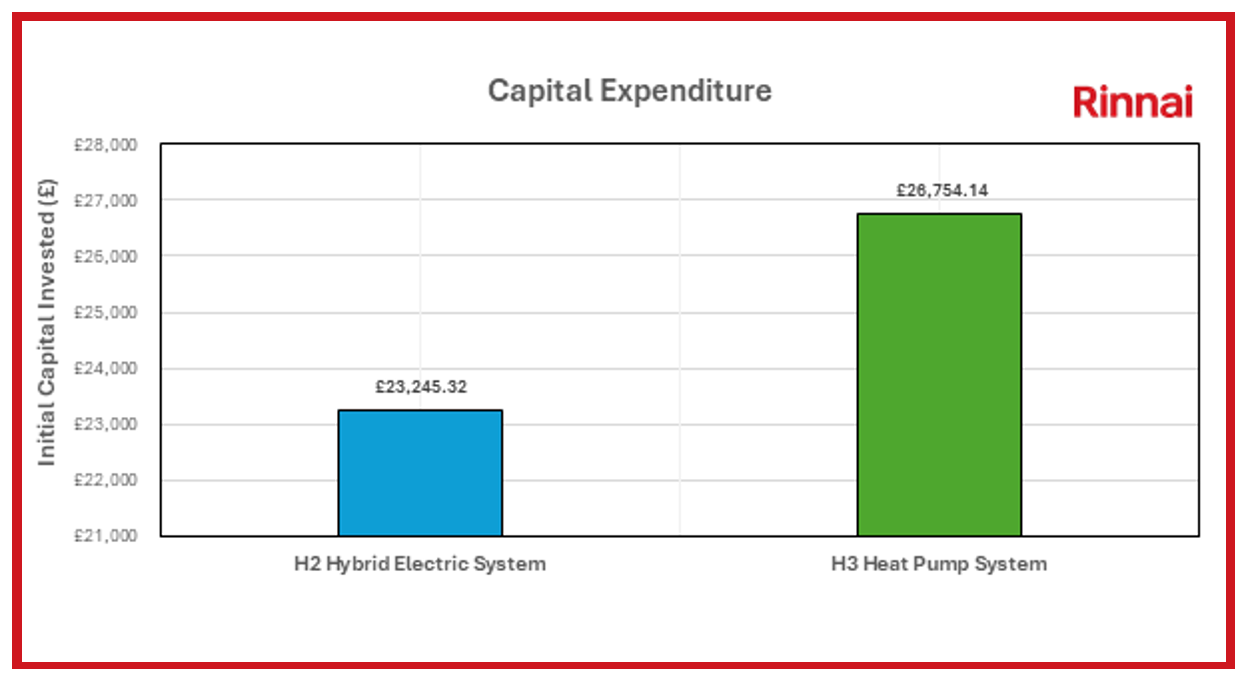

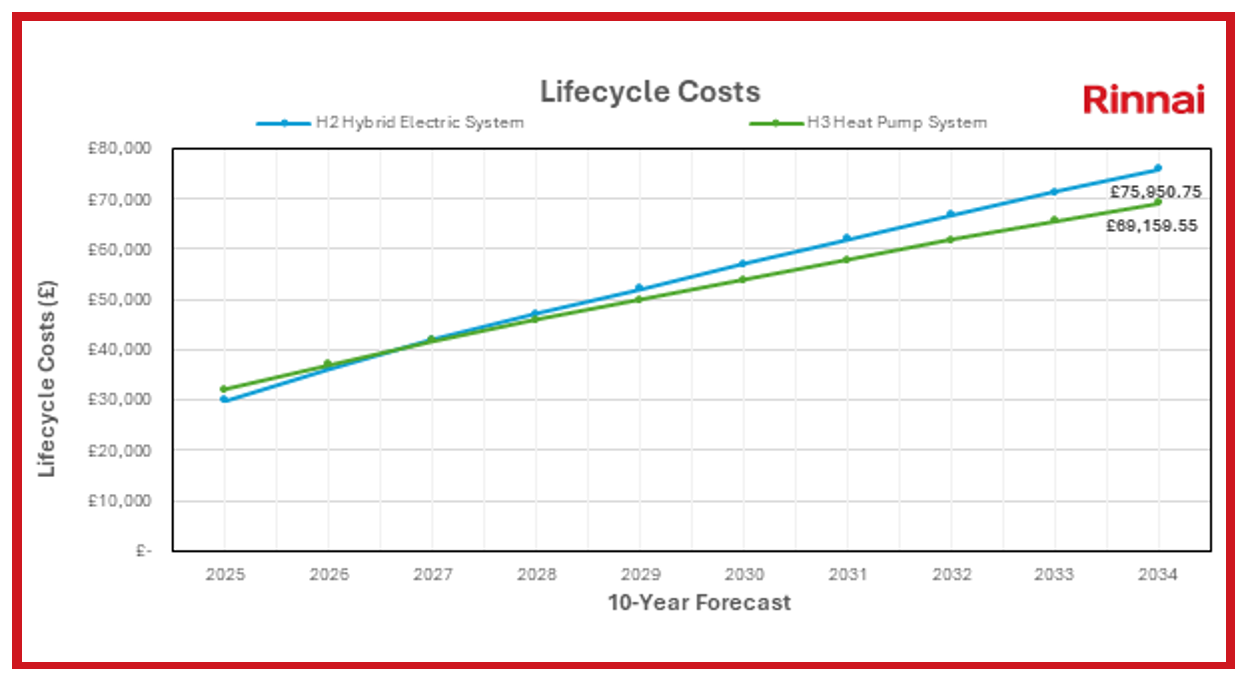

The following data was used to enable the client to make an informed choice. The graphs analysis SPF (seasonal performance factors), Operational expenditure, carbon produced, Capital expenditure and the life cycle costs between the Rinnai H2 Hybrid water heating system and Rinnai’s H3 Heat Pump system. The H2 hybrid system is represented in blue whilst the H3 heat pump system is represented in green.

The SPF graph portrays that when taking the entire system efficiency into account, the H2 Hybrid Electric system has an average SPF of 2.50, while the H3 Heat Pump System has an average SPF of 2.72. The key reason for the drop in efficiency of the H2 system is the inclusion of electric cylinders, as opposed to generating all heated water via higher efficiency heat pumps.

The operating expenditure graph shows the H2 hybrid system always has a higher OPEX than the H3 heat pump system across a 10-year period. The H2 system will cost approximately £52,705, while the H3 system will cost around £10,000 less at £42,405, considering a 19.5% decrease in operating costs. The H2 hybrid system requires more grid sourced electricity to be purchased because the efficiency of the electric immersion cylinder is less than the R290 Heat Pump.

When comparing the carbon produced across a 10-year period the H2 system will emit 20,584kg of CO2 whilst the H3 system will emit just 16,562kg of CO2. This demonstrates a 24.3% decrease in carbon production.

CAPEX costs associated with the H2 hybrid electric system will cost £23,245, the H3 heat pump system will cost £26,754, a 13% increase. The reason for the increase is that heat pumps can cost more than electric immersion cylinders. This gives the customer an option of reducing initial expenditure if budget constraints exist.

When combining the CAPEX and OPEX data, lifecycle costs over a 10-year period can be forecast. This reinforced that the H3 Heat Pump system will cost less over its lifetime compared to the H2 Hybrid Electric System. The H3 Heat Pump system will save the customer £6,791 over a 10-year period and will take just two years to become comparable with the H2 Hybrid Electric option.

Sign up for a free CIBSE accreditation SPF CPD today! https://www.rinnai-uk.co.uk/training/cibse-cpd-training-enrolment

Rinnai understands the UK customer requirement for cost effective and robust appliances that consistently deliver clean hot water and heating to domestic and commercial buildings across the UK. Rinnai are committed to offering UK customers low cost and practical solutions that cover all energy options.

RINNAI OFFERS CLEAR PATHWAYS TO LOWER CARBON & DECARBONISATION

PLUS CUSTOMER COST REDUCTIONS FOR COMMERCIAL, DOMESTIC &

OFF-GRID HEATING & HOT WATER DELIVERY

- Rinnai’s range of decarbonising products – H1/H2/H3 – consists of hot water heating units in gas/BioLPG/DME, hydrogen ready units, electric instantaneous hot water heaters, electric storage cylinders and buffer vessels, a comprehensive range of heat pumps, solar, hydrogen-ready or natural gas in any configuration of hybrid formats for either residential or commercial applications. Rinnai’s H1/2/3 range of products and systems offer contractors, consultants and end users a range of efficient, robust and affordable low carbon/decarbonising appliances which create practical, economic and technically feasible solutions.

- Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

- Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours.

- Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question.

- Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s.

- The Rinnai range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

CLICK HERE TO VISIT THE RINNAI WEBSITE

or HERE to EMAIL RINNAI

CLICK HERE For more information on the RINNAI product range