ROCKWOOL® launches low lambda non-combustible insulation for external walls

NyRock® Rainscreen 032 and Frame Slab 032 are manufactured using the UK’s most thermally efficient stone wool insulation enabling thinner wall constructions

ROCKWOOL has launched NyRock® Rainscreen 032 and Frame Slab 032, the first in a series of products that use NyRock technology, a patented production process that delivers the lowest lambda stone wool insulation available in the UK.

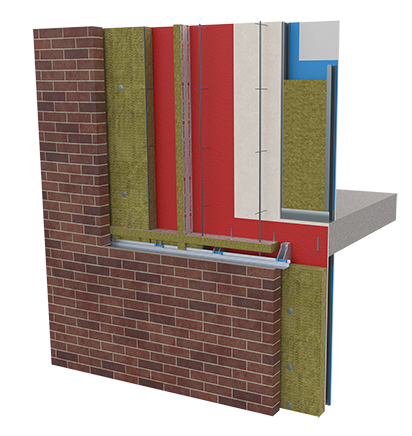

NyRock Rainscreen 032 is specifically developed for ventilated cladding systems and sealed structures such as curtain walling. It combines a low thermal conductivity of 0.032 W/mK and a non-combustible Euroclass A1 rating along with independently tested acoustic performance and the potential for thinner wall constructions.

Manufactured using patented technology, NyRock Rainscreen 032 has a more efficient fibre structure than traditional stone wool products, resulting in improved thermal properties. This fibre structure also helps to lessen the transfer of airborne noise, with NyRock Rainscreen 032 achieving a sound reduction index of up to Rw 60 dB when assessed as part of a typical system in independent in-situ laboratory testing.

Created for straightforward installation as well as ongoing performance, the product can be easily fitted around brackets and other challenging details, with slabs designed to ‘knit together’ when tightly butted providing a continuous insulating layer that reduces thermal bridging.

For optimum thermal performance in framed structures, NyRock Rainscreen Slab 032 should be combined with NyRock Frame Slab 032, a further new addition to the NyRock range, that is purpose designed for fitting between the studwork of external timber or light gauge steel frame walls.

Combined, NyRock Rainscreen 032 and Frame Slab 032 enable U-values to be met with a thinner wall construction versus standard stone wool solutions.

Paul Barrett, Head of Product Management at ROCKWOOL explains: “When working to a U-value of 0.18 W/m2K, specifiers can typically save around 15mm on the wall thickness compared to traditional stone wool products. Applying that saving over a 22m x 22m building of nine storeys, for example, it can yield an extra 99 square feet of usable or profitable floor space[1].

“The balance between building performance, sustainability and commerciality is a constant challenge for specifiers and building owners. Our NyRock range has been created understanding those pressures, hence deliver lower lambda for thinner walls, while also providing the additional benefits of stone wool including non-combustibility.”

Like its rainscreen counterpart, NyRock Frame Slab 032 can withstand temperatures in excess of 1000°C, achieving the highest Euroclass A1 non-combustible reaction to fire classification.

As well as suited to ventilated façade systems, NyRock Frame Slab 032 can be used in a variety of external timber or steel frame applications, including with a brick outer and with or without a service void. NyRock Frame Slab 032 is available in 570mm widths for timber or 600mm for steel ensuring quick, easy friction fitting into frame walls. Its strong dimensional stability when fitted under compression also accommodates building movement, without slumping and sagging, or a loss in thermal performance[2].

All ROCKWOOL stone wool insulation comprising NyRock technology provides water resistance plus can be recycled indefinitely. Stone wool insulation is manufactured from naturally occurring volcanic rock that is abundant in supply as it is continually replenished by the earth’s crust.

CLICK HERE

For more details on NyRock Rainscreen 032 and Frame Slab 032,

including datasheets.

[1] Based on 22m x 22m building with nine storeys and allowing for 20% load factor

[2] FIW (German test and research institute), Durability Project Mineral Wool, 2016

Paul Barrett, Head of Product Management at ROCKWOOL explains: “When working to a U-value of 0.18 W/m2K, specifiers can typically save around 15mm on the wall thickness compared to traditional stone wool products. Applying that saving over a 22m x 22m building of nine storeys, for example, it can yield an extra 99 square feet of usable or profitable floor space

Paul Barrett, Head of Product Management at ROCKWOOL explains: “When working to a U-value of 0.18 W/m2K, specifiers can typically save around 15mm on the wall thickness compared to traditional stone wool products. Applying that saving over a 22m x 22m building of nine storeys, for example, it can yield an extra 99 square feet of usable or profitable floor space

Leave a Reply

Want to join the discussion?Feel free to contribute!