EJOT’s Anchor Fix 2025 software makes anchor dimensioning and selection even easier

Free to download, EJOT’s Anchor Fix enables different fastening options to be compared

with ease, and it allows the modular design concept for the LIEBIG range of heavy

duty anchors to be fully utilised for the first time in a digital environment.

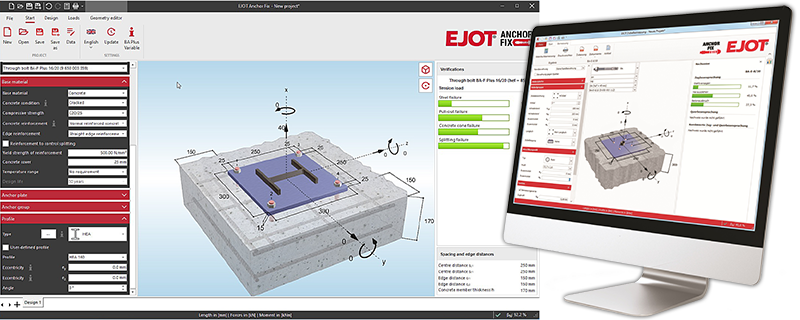

A new version of EJOT’s Anchor Fix software makes the process for developing anchoring designs and specifications for heavy-duty and safety-critical applications easier than ever.

The software, which is free to download from the EJOT website, enables different fastening options within the EJOT through-bolt, resin anchoring and LIEBIG heavy-duty anchor ranges to be compared with ease. To date, Anchor Fix has been downloaded by thousands of engineers and technicians around the world who have been able to streamline their anchor dimensioning and calculation process to save time and cost.

Increased flexibility is the key benefit of the comprehensively updated version of this popular anchor dimensioning software, with new functionality to compare both standard and bespoke fastening options for different applications for the first time. It also allows the safest approach to be calculated in line with all applicable standards and design codes, and for the most appropriate products to be determined with confidence.

A key upgrade from the original version of Anchor Fix is the ability to carry out a design specifically according to the application requirements, rather than being constrained by the restrictions of the current design code EN 1992-4 (Eurocode 2: Design of concrete structures – Design of fastenings for use in concrete).

EJOT’s range of high performing anchoring solutions is supported by extensive technical guidance and on-site testing.

This is an important expansion to the software’s scope, enabling designs to be developed where the baseplate and anchor geometry falls outside of the scope of the design code. In addition, all calculations are backed with accurate and up to date code compliance or engineering judgment for all design outputs.

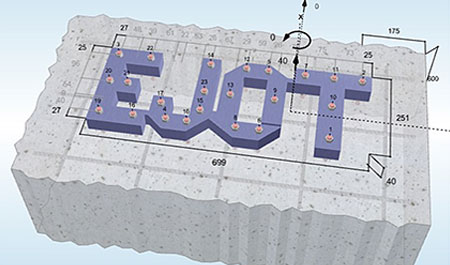

This means Anchor Fix’s new capabilities allow the modular design concept of the LIEBIG range of heavy-duty anchors to be fully utilised for the first time in a digital environment. Designs can be achieved using readily available special-length anchors which are covered under the same ETA approvals as all standard-length anchors, increasing the flexibility available within Anchor Fix and improving the speed of design for specifiers and engineers alike.

Another important feature improved in the latest Anchor Fix is the process for optimising cost and efficiency. Identifying the most cost-effective anchor to meet all of the design input requirements is now more straightforward, and it also assists when tasked with value engineering a solution to achieve a reduction in the total installed cost without compromising performance.

Paul Papworth, EJOT UK’s anchoring specialist said:

“Anchor Fix 2025 builds on the strengths of the original version of the software by providing extra functionality, particularly to leverage the value of bespoke length anchors available within our modular LIEBIG range. Mechanical anchors including Ultraplus and Superplus BLS can be produced in custom-lengths to meet the requirements of even the most challenging anchoring projects, which is why we wanted to ensure Anchor Fix made these options available at the design stage.

“In creating Anchor Fix 2025, our developers have achieved a new software release which is still based on the latest ETA data, the latest design approach, governed by EN1992-4, but with the ability to plot the actual connection design within the program as a non-regular baseplate or anchor group arrangement. This, in turn, will yield multi-product options supported by a report referencing the EN standard and/or manufacturer verification of the calculation.

“Once the anchoring design and specification is confirmed and work begins on site, EJOT’s support continues with installation trials and tool-box-talks to ensure installers are correctly trained to achieve the optimum results. This gives us the opportunity to partner with designers and contractors from ‘Concept through Construction to Commissioning’ – it is what we call our 3C total support approach.”

A scope-broadening upgrade means Anchor Fix can now carry out a design specifically according to the application requirements, rather than being constrained by the current design code EN 1992-4.

Anchor Fix is part of an extensive package of support available from EJOT UK to help customers achieve the most effective anchoring solutions. The technical team, led by Paul Papworth, works closely with customers in a number of ways, including developing unique calculations for more complex anchoring projects, drawing on the complete EJOT and LIEBIG portfolio to make fully compliant recommendations.

In addition, EJOT UK has the facilities to conduct a variety of tests to confirm the performance of its proposed anchoring approach. This includes laboratory tests at its state-of-the-art research, development and testing facility, called the Applitec Centre, at its Yorkshire HQ and on-site pull-out tests.

CLICK HERE to find out more about Anchor Fix

Leave a Reply

Want to join the discussion?Feel free to contribute!