EJOT CROSSFIX® helps shape the future of sustainable housing

The construction of two apartment buildings within the ground-breaking Climate Innovation District urban regeneration project in Leeds demonstrates how the EJOT CROSSFIX® substructure system can be used to incorporate rainscreen facades into highly sustainable buildings, without vastly increasing insulation depth.

Developed by Citu in partnership with one of Scandinavia’s leading architectural practices, White Arkitekter, and civil and structural engineers Civic, the scheme is creating an entire new sustainable neighbourhood with high quality urban housing. Over 500 low energy homes with integrated amenities have been created to a design that has been PHPP (Passive House Planning Package) assessed.

The development’s two apartment buildings, known as volumes, feature a mix of private sale and affordable housing in line with the planning consent, with nine social rent apartments and seven sub-market intermediate units incorporated.

Both volumes, named Aire Lofts and District Lofts, are constructed using a steel structure with composite metal deck floors and a light gauge steel framing system. This facilitates a rear ventilated façade (RVF) featuring two types of Swisspearl fibre cement panels externally, providing a consistent aesthetic across both multi-storey buildings, which rise up to 10 floors in height.

EJOT CROSSFIX® was selected to provide the critically important substructure because it enabled the construction of a highly insulated façade without compromising aesthetics, with the added benefit of streamlining installation.

Meeting multiple performance goals

The entire façade of District Lofts was constructed by Hansen Facades using CROSSFIX, in conjunction with main  contractor Artium Construction. It was chosen following its successful deployment on Aire Lofts, where the system’s versatility and effectiveness were first recognised by Citu after it was used for secret-fix panels used to demarcate duplex apartments at the ground and first floor levels.

contractor Artium Construction. It was chosen following its successful deployment on Aire Lofts, where the system’s versatility and effectiveness were first recognised by Citu after it was used for secret-fix panels used to demarcate duplex apartments at the ground and first floor levels.

The EWS1 (External Wall System 1) rating of the facades for both volumes meant that the materials used in their construction, inclusive of specified attachments, had to be A1 ‘non-combustible’, signifying the best possible rating with minimal fire risk. Optimising the fire performance included the incorporation of FSi open and closed state cavity barriers, along with RCM Y-Wall A1 non-combustible sheathing boards.

These fire safety objectives were balanced with thermal and ventilation goals. Given the high thermal requirements, the substructure cavity had to be sufficiently deep to accommodate Rockwool Duo-Slab insulation with a thickness of 250mm and maintain the required ventilation for a system of this type.

The deep layer of insulation was one of the most important façade components needed for both buildings from a thermal perspective. The facades had to meet a weighted U Value (based on a typical subframe arrangement) of 0.13 W/m²k, which was key to delivering on the developer’s commitment to providing homes with heating energy demand around five times lower than the average UK house. However, CROSSFIX was also instrumental in making this high level of thermal performance a reality.

A sustainable façade enabler

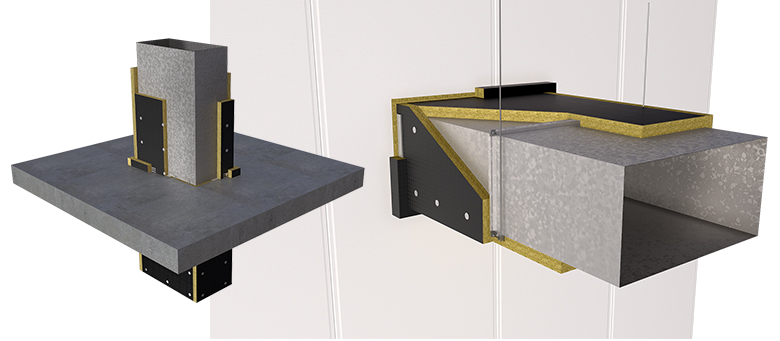

The CROSSFIX substructure consisted of a 220mm Konsole K1 in A2 stainless steel, complete with the Powerkey for enhanced structural stability in the same metal grade, which supported L, Z and T profiles. The EJOT package was completed with five types of stainless steel fasteners to provide secure assembly with consistent performance.

CROSSFIX’s stainless steel composition made an important contribution to meeting the façade’s thermal performance goals given its very low thermal conductivity, which minimises the potential for thermal bridging. Coupled with a thermal stop incorporated into the CROSSFIX Konsole, this meant the facade’s U-value is lower than it would have been if other types of substructures had been used with the same thickness of insulation.

In addition, considering the whole life cycle of the products, CROSSFIX is mainly formed of recyclable stainless steel which requires significantly less energy to manufacture compared to the materials used in other RVF substructure systems – confirmed by an Environmental Product Declaration (EPD).

A smart solution for modern construction methods

The multiple sustainability benefits provided by CROSSFIX, enhanced further through the ‘non-flammable’ fire resistance rating of the system and a unique design flexibility that enables it to be used in both horizontal and vertical assembly, means it aligns well with the higher efficiency, safety and quality targets demanded in modern construction.

In addition, at the Climate Innovation District, valuable efficiency benefits were delivered because CROSSFIX does not require special or handed brackets in areas of the façade where space is limited, such as between windows and other openings. The versatility of the substructure also meant that one subframe system could be used for both the secret-fix and face-fixed cladding.

CLICK HERE TO FIND OUT MORE

Leave a Reply

Want to join the discussion?Feel free to contribute!