Developing Self-Healing Concrete

Source: IDTechEx

Self-Healing Materials Market to Build on Success in the Construction Industry

Every year, industrialized nations lose approximately 3% of GDP due to issues associated with material corrosion and degradation. In particular, damage to concrete structures and infrastructure, ranging from small cracks to complete failure, can lead to severe disruptions, and repairs can incur significant expense. But what if damaged concrete had the ability to self-heal microcracks before they could propagate into larger-scale issues?

In IDTechEx’s report, “Self-Healing Materials 2025-2035: Technologies, Applications, and Players“, a detailed overview of the market is given, including insights into technical challenges and progress, key sectors for market growth, and commercial readiness levels. A third-party, independent assessment of the market is provided throughout, including an unbiased outlook for the covered materials and industry sectors.

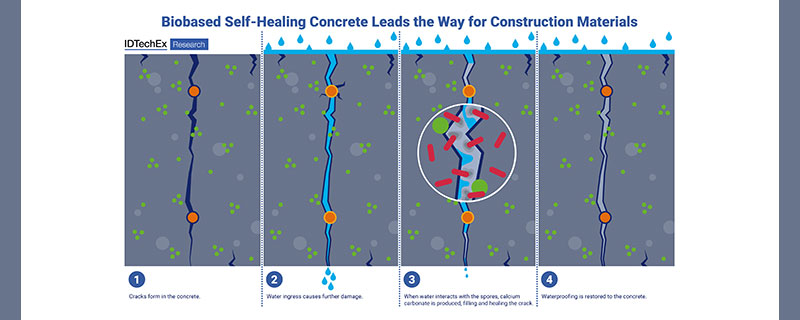

Concrete typically fails due to the development of microcracks, which gradually expand into larger cracks. Freeze-thaw action can be a major issue, where water fills cracks before freezing and expanding, causing further damage in a repetitive cycle. Self-healing concrete is designed to repair these microcracks efficiently. Many technologies exist, but IDTechEx research finds that biological approaches lead the way for the successful commercialization of self-healing concrete.

An ancient approach

Rome wasn’t built in a day, but many of its most beautiful buildings and structures have stood the test of time, remaining standing over two millennia after their construction. Roman concrete is composed of quicklime (calcium oxide), volcanic ash, and water, and was produced at high temperatures using a technique called “hot mixing.” Studies have revealed the presence of lime clasts (calcium-rich mineral deposits) visible in Roman architecture as small, distinct white features measuring a few millimeters in size.

When a crack forms, water infiltrates, and a calcium-enriched solution is created. Despite detailed research, two proposed healing mechanisms exist. In the most straightforward scenario, the solution heals the crack itself. The second and more complex mechanism is known as the Pozzolanic reaction and involves the formation of several intermediates at the interface between the volcanic aggregate and the surrounding matrix.

Modern methods

A promising approach, from players such as Basilisk, involves embedding mineral-producing bacteria into concrete for self-healing purposes. These acid-producing bacteria can remain dormant for over 200 years and serve as catalysts in the crack-repair process. When cracks develop, the bacteria become active, consuming calcium lactate and generating limestone to seal the damage. Bacterial strains used in construction include Bacillus pasteurii, B. sphaericus, B. subtilis, B. cohnii, B. halodurans, and B. pseudofirmus.

The healing process occurs through a biological reaction between unreacted limestone and a calcium-based nutrient. When bacterial spores encounter water, they begin to feed on the calcium lactate, a process that consumes oxygen and helps reduce the risk of steel corrosion. The soluble calcium lactate is converted into insoluble limestone, which hardens and fills the crack.

Alternative approaches to self-healing construction materials are also discussed in the IDTechEx report. Geopolymer concrete is produced from waste materials such as fly ash, and self-healing mechanisms have been proposed, while there is also a compelling method utilizing bacteria-coated fibers. The major benefit is that the core of the fiber acts like a stitch and holds the crack closed, restricting the propagation of the crack and minimizing the extent of self-healing that is required.

Concrete offers a high-volume route to market for self-healing materials, allowing confidence and trust to be built in the novel approach to increasing the lifespan of structures. Initial risks can be lowered by considering only slabs, with vertical pours for walls delayed until phase two of adoption. From an economic perspective, IDTechEx’s assessment of the market reports a 30% increase in material costs when adding self-healing properties; however, these can be accounted for in a number of ways. Saving on the aforementioned GDP loss, reduced need for replacements, minimized maintenance, and limited downtime can all be summed up in the life-cycle costs that are reduced in total when considering self-healing concrete.

The “Self-Healing Materials 2025-2035: Technologies, Applications, and Players” report provides an in-depth analysis of this emerging market. Leveraging its expertise in advanced materials, IDTechEx delivers an independent evaluation, covering technology comparisons, industry trends, and key player assessments, offering valuable insights into this promising but still-developing sector.

Dr Conor O’Brien, Senior Technology Analyst at IDTechEx

Leave a Reply

Want to join the discussion?Feel free to contribute!