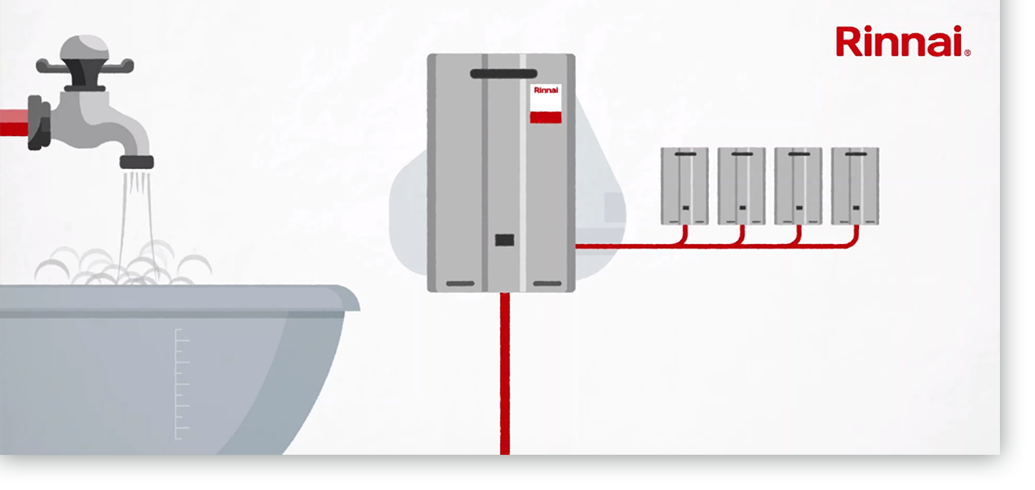

Rinnai has given a local community’s much-loved sports pavilion a replacement DHW system which upgrades from its old cylinder system and provides the same peak-time capacity with significantly reduced energy costs along with much lower emissions through utilising the Rinnai R290 heat pump system.

Rinnai offered a choice of solutions all with capital, operational and carbon modelling as part of the offering, so that the decision makers could select the optimum solution for their needs. Based upon the data the site specifically requested an Air-Source Heat Pump replacement.

As a part of the bespoke design service offered by Rinnai three possible solutions were put forward, each with differing recovery times ranging from between two and four hours, with the 2000L in storage staying consistent with the old system’s capacity.

After full consultations with the site and the contractor, the system chosen was the 40kW R290 air source heat pump system. Despite the two other possible systems offering quicker recovery periods the client opted for one single heat pump unit. An additional factor governing the decision was the fact that the 40kW R290 system, incorporating 2 x1000 L cylinders, emitted less carbon and was more economical to run in the long term

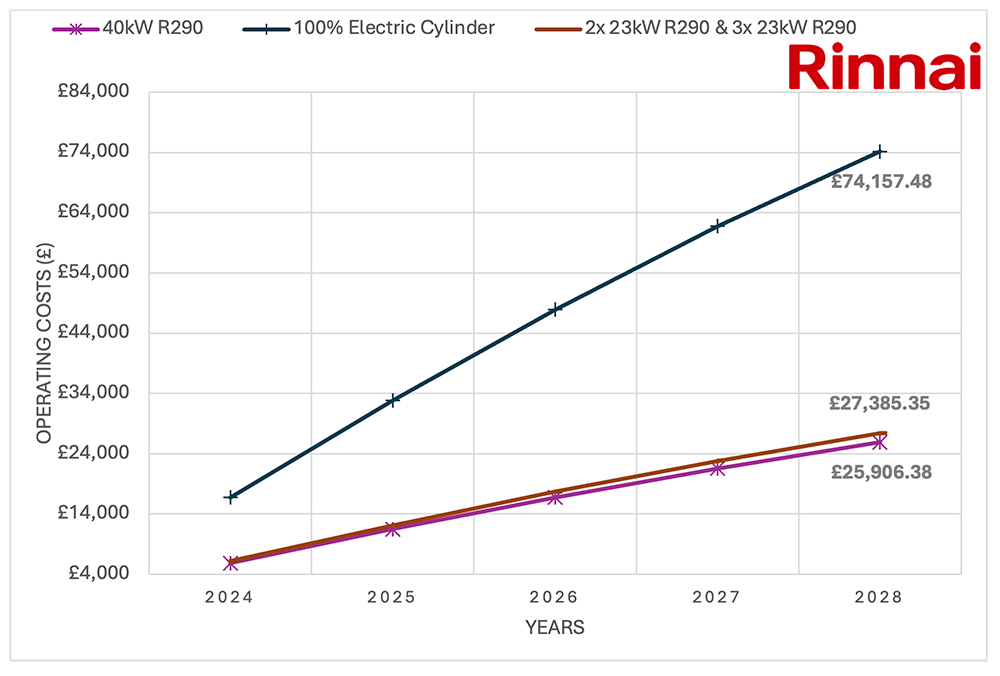

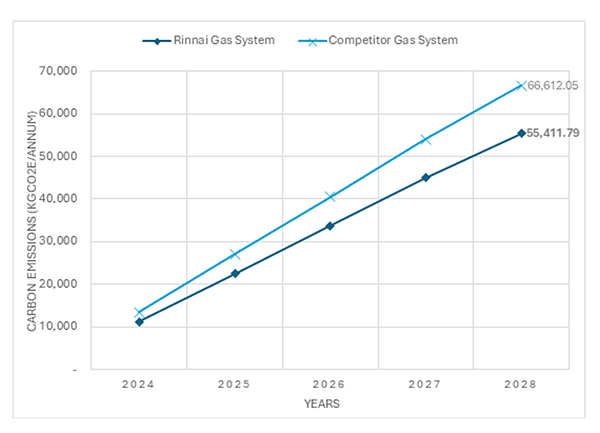

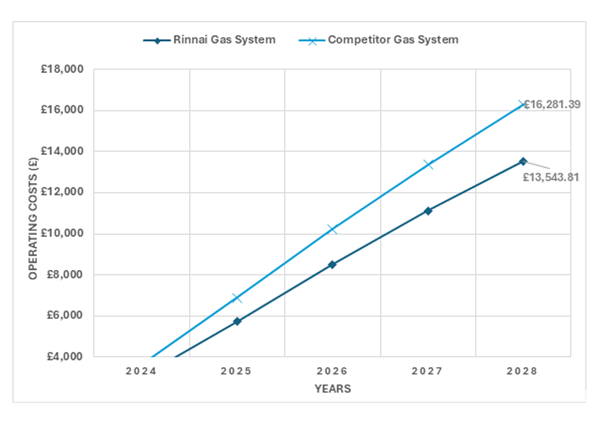

Cumulative Running Costs (OPEX) comparing a H1 and a H3 system for DHW

Cumulative Running Costs (OPEX) comparing a H1 and a H3 system for DHW

This graph shows the cumulative running costs of each of the three possible systems across a 5-year period. As shown from the data the original system is significantly more expensive to run compared to the H3 systems. With a £46,772.13 or 170% increase compared to the 23kW R290 systems and a £48,251.10 or 186% increase compared to the 40kW R290 system by year 5.

The successful implementation of the Rinnai R290 air source heat pump system at the Surrey Sports Pavilion demonstrates the effectiveness of Rinnai’s bespoke design services and complete packaged solutions. By upgrading to a more efficient and environmentally friendly system, the pavilion now enjoys reduced carbon emissions, while maintaining the necessary capacity for peak-time demand. This project highlights Rinnai’s commitment to providing tailored solutions that meet the specific needs of all type of buildings to experience this service for your next project.

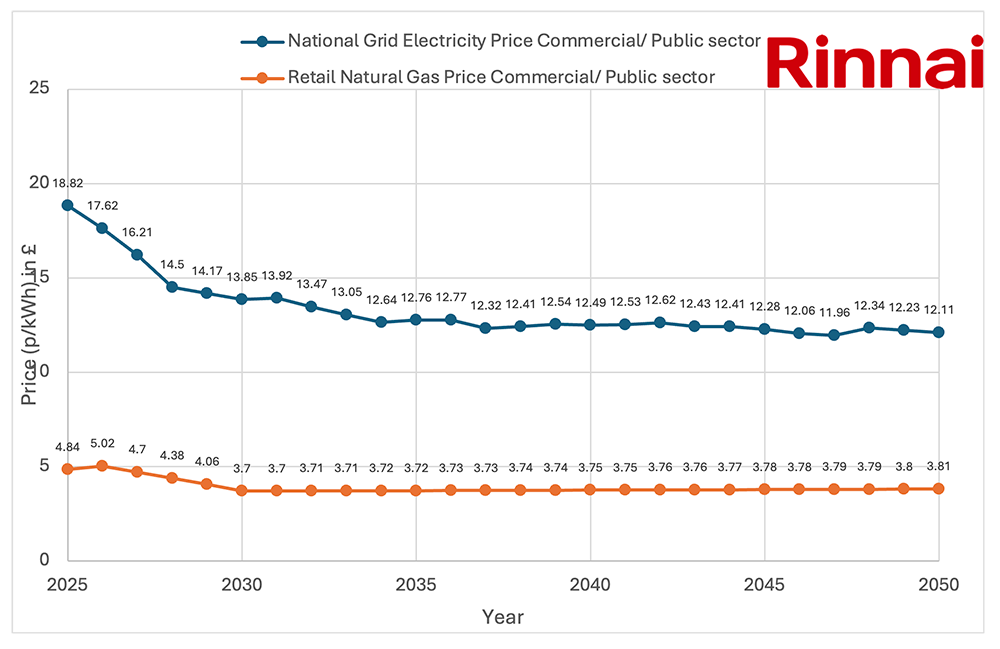

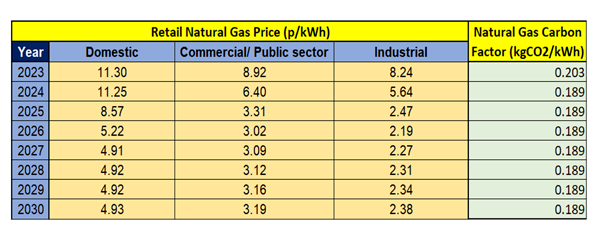

Comparison of Energy Prices of National Gas and National Grid Electricity Between 2025 & 2050

Energy Prices of National Gas and National Electricity Grid

UK energy strategists believe that clean and sustainable electrification is presently one of the best modes of reducing carbon emissions, maximise efficiencies and to also lower end-user customer costs.

Rinnai is determined to offer UK customers assorted options of carbon reducing technology that ensures an improved healthy lifestyle. Rinnai is also keen on informing all UK customers in major changes and developments concerning the international energy market that may affect purchase or power options in the near and far future.

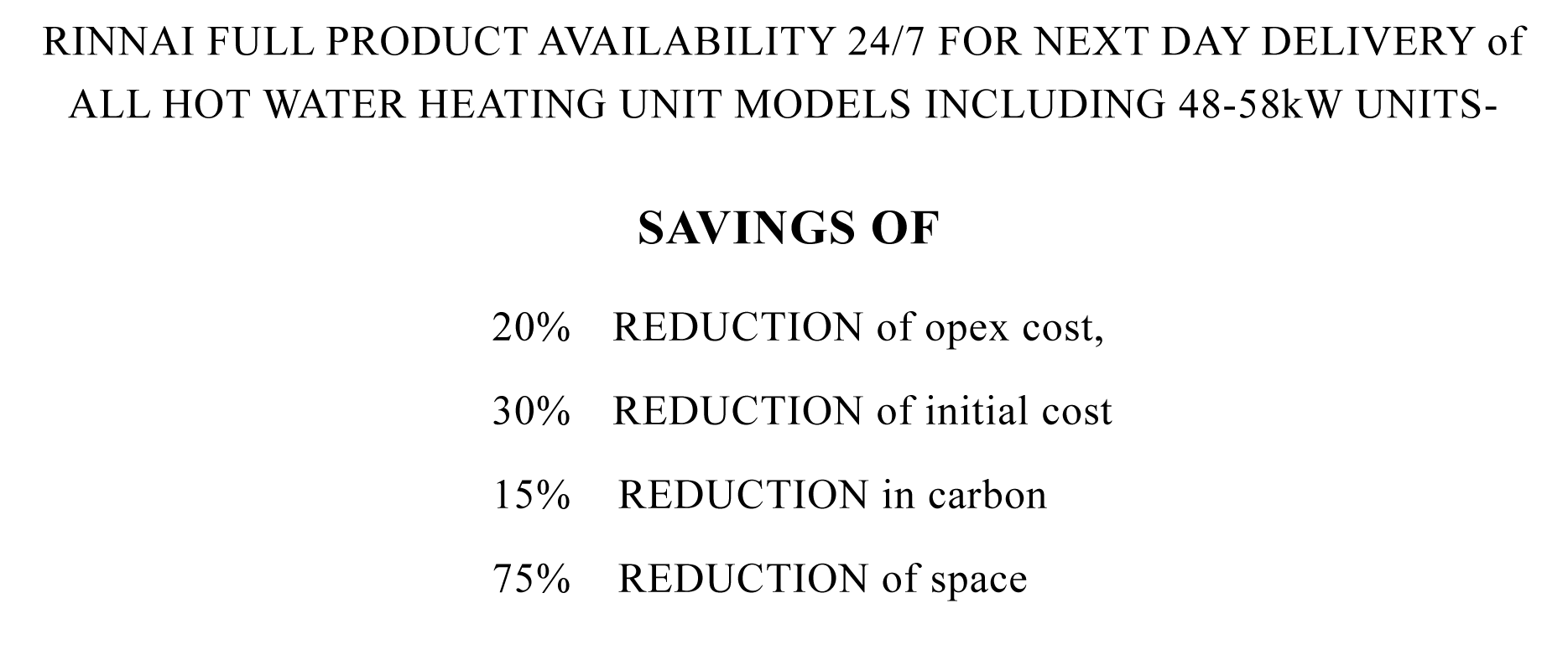

RINNAI OFFERS CLEAR PATHWAYS TO LOWER CARBON & DECARBONISATION

PLUS CUSTOMER COST REDUCTIONS FOR COMMERCIAL, DOMESTIC &

OFF-GRID HEATING & HOT WATER DELIVERY

- Rinnai’s range of decarbonising products – H1/H2/H3 – consists of hot water heating units in gas/BioLPG/DME, hydrogen ready units, electric instantaneous hot water heaters, electric storage cylinders and buffer vessels, a comprehensive range of heat pumps, solar, hydrogen-ready or natural gas in any configuration of hybrid formats for either residential or commercial applications. Rinnai’s H1/2/3 range of products and systems offer contractors, consultants and end users a range of efficient, robust and affordable low carbon/decarbonising appliances which create practical, economic and technically feasible solutions.

- Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

- Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours.

- Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question.

- Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s.

- The Rinnai range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

CLICK HERE TO VISIT THE RINNAI WEBSITE

or HERE to EMAIL RINNAI

CLICK HERE For more information on the RINNAI product range

Via SIG Tyneside, AIM has supplied the Acoustic Trough Infills for two large roof areas to Wates’ contractor Chemplas, the North East-based roofing, cladding and glazing company.

Via SIG Tyneside, AIM has supplied the Acoustic Trough Infills for two large roof areas to Wates’ contractor Chemplas, the North East-based roofing, cladding and glazing company.