Chris Goggin explains the approach to the relentless pursuit of manufacturing excellence, including the two separate methodologies of “Kaizen” and “Kanban,” that are central to Rinnai manufacturing excellence.

Japanese manufacturing industries are acknowledged as global leaders in innovation, efficiency, and product durability and longevity. Japanese companies have consistently maintained their competitive edge and endured the test of time. As many use the “Kaizen” and “Kanban” approach to manufacture.

These are two distinct methodologies that are adopted into the daily operations of Rinnai, and they ensure the highest levels of manufacturing standards. The term ‘Kaizen’ has come to mean “continuous improvement,” in a professional context. A broader interpretation can be translated as continuous improvement in personal life, home life, social life and working life.

A Kaizen approach focuses on implementing gradual and incremental changes that will produce long-term improvements in professional efficiency and quality. The main principles that facilitate the concept of Kaizen are:

Know Your Customer

Let it Flow

Go to Gemba

Empowering People

Be Transparent

“Know Your Customer” identifies what is truly required by the customer to deliver an enhanced end-product that satisfies demand.

“Let it Flow” concentrates on creating a smooth flow of processes and practices that identifies and eliminates production bottlenecks whilst reducing customer waiting times. This principle focuses on eliminating waste in all aspects of the commercial operation – waste is viewed as any culture or practice that does not benefit the customer or encourage professional productivity.

“Go to Gemba” translates as being always concerned with all matters in every department.

“Be Transparent” uses and measures data that improves company progress.

“Empower People” relates to providing appropriate tools to successfully complete group targets that maximise production efficiency.

Kanban is a philosophy that seeks to encourage continuous improvement in production and business methods by measuring project progress through visual Kanban boards. The Kanban methodology was invented by Toyota engineer Taiichi Ohno during the late 1940s. The term “Kanban” when broken down into two words from Japanese to English means “Kan” (sign)” and “Ban” (board).

A Kanban approach was employed to improve Toyota’s production system by incorporating elements of lean manufacturing into their process. Kanban framework allowed Toyota to transition from a “push” process (products are pushed on to the market) into a “pull” system (products that are created due to market demand). This idea allows companies to risk low inventory levels whilst remaining competitive.

Kanban is also referred to as the “Just in Time” (JIT) system, as production can concentrate on creating products because of consumer demand as opposed to manufacturing products that rely on anticipated demand.

Kanban boards are organised into columns – each column contains visual cards that represent a task during a separate stage of work. The team can easily track task progress and share necessary information that assists in task completion. Kanban boards are an agile and fluid visual form of measuring group progress during the completion of a task.

The creator of the Kanban framework Taiichi Ohno maintains strong links to Rinnai and has had a discernible influence and impact on Rinnai’s production system. Ohno visited Rinnai’s Japanese production plant and provided critical observations and advice that led to Rinnai adopting lean manufacturing principles that enhanced product producing efficiency.

Both Kaizen and Kanban frames of thought assist Rinnai’s manufacturing process that delivers millions of products per year all manufactured under strict guidelines of ISO 9001 quality management and ISO 14001 environmental management systems. Ensuring Rinnai can deliver market leading warranties (up to 12 years) for its continuous flow of water heater range.

Commercial Condensing Water Heaters: Models: N-1300, N-1600 Internal, N-1600 External are all provided with a standard warranty of 3 years for all parts, which can be extended up to 12 years.

Domestic Gas Multi-Point Water Heating: purchasing a Rinnai Tankless11i, 16i, 17i,17e means that customers will be provided with a 3-year warranty for the heat exchanger and all other components.

For further information pertaining to Rinnai warranties & products

or to ask us a question

Additionally, after manufacturing and offering warranties, Rinnai offers a comprehensive range of FREE services to all UK customers. Rinnai offers system designs, carbon reduction calculations, technical services as well as commissioning and delivery to site in one single consignment.

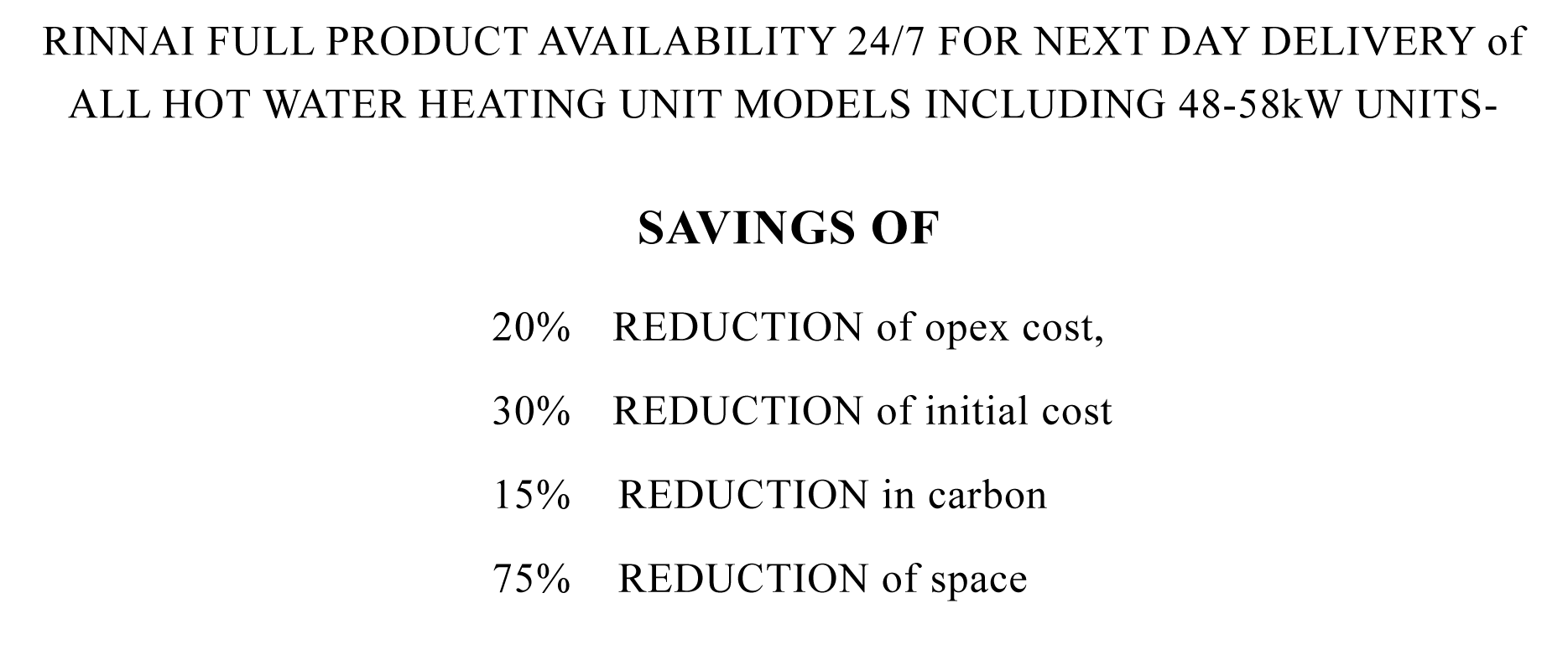

“Rinnai’s services are designed to provide comprehensible purchase options, system design, CAPEX, OPEX and carbon calculations as well as whole consignment delivery to any UK site upon 24 hours of purchasing,” says Technical Head Pete Seddon.

Rinnai’s specialist design team can provide a “Site Consultation Form” that details on-site data of current heating and hot water system capabilities. Customers can view the results in a rapid low carbon replacement suggestion by a professional team member.

Rinnai services include a carbon and cost comparison service that offers a free appraisal of any site’s current heating & hot water delivery system, along with empirically gathered data driven recommendations for reducing carbon load and all related costs.

If a customer encounters difficulties when selecting a product, a “Help Me Choose” service option is available

This service enables easier product selection through direct contact with a Rinnai professional

RINNAI’S H3 DECARBONISATION OFFERS PATHWAYS & CUSTOMER COST REDUCTIONS

FOR COMMERCIAL, DOMESTIC AND OFF-GRID HEATING & HOT WATER DELIVERY

Rinnai’s H3 range of decarbonising products include hydrogen / BioLPG ready technology, hybrid systems, and a wide range of LOW GWP heat pumps and solar thermal. Also, within Rinnai’s H3 range is Infinity hydrogen blend ready and BioLPG ready continuous flow water heaters which are stacked with a multitude of features that ensure long life, robust & durable use, customer satisfaction and product efficiency.

Rinnai’s range of decarbonising products – H1/H2/H3 – consists of heat pump, solar, hydrogen in any configuration, hybrid formats for either residential or commercial applications. Rinnai’s H3 range of products offer contractors, consultants and end users a range of efficient, robust and affordable decarbonising appliances which create practical, economic and technically feasible solutions. The range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters.

Rinnai H1 continuous water heaters and boilers offer practical and economic decarbonization delivered through technological innovation in hydrogen and renewable liquid gas ready technology.

Rinnai’s H1 option is centred on hydrogen, as it is anticipated that clean hydrogen fuels will become internationally energy market-relevant in the future; Rinnai water heaters are hydrogen 20% blends ready and include the world’s first 100% hydrogen-ready hot water heating technology.

Rinnai H2 – Decarbonization simplified with renewable gas-ready units, Solar Thermal and Heat Pump Hybrids. Rinnai H2 is designed to introduce a practical and low-cost option which may suit specific sites and enable multiple decarbonisation pathways with the addition of high performance.

Rinnai H3 – Low-GWP heat pump technology made easy – Rinnai heat pumps are available for domestic and commercial usage with an extensive range of 4 – 115kW appliances.

Rinnai’s H3 heat pumps utilise R32 refrigerant and have favourable COP and SCOP.

Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

Rinnai’s commercial and domestic continuous flow water heaters offer a limitless supply of instantaneous temperature controlled hot water and all units are designed to align with present and future energy sources. Rinnai condensing water heaters accept either existing fuel or hydrogen gas blends. Rinnai units are also suited for off-grid customers who require LPG and BioLPG or DME.

Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours. Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question. Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s.