Chris Goggin reviews the UK’s approach to extending and enhancing electrical grid connections to recently constructed renewable energy projects. He looks at how focus could be applied to the potential impact on UK customer options.

For more opinion pieces on UK energy and policy

CLICK HERE to subscribe to our newsletter

Every major country is trying to decarbonise all industrial and commercial operations, knowing that current fossil fuel usage is environmentally unsustainable. Therefore, each notable international economy is currently drafting future energy policy objectives that complement respective domestic energy mixes.

It is a widely believed amongst professionals inside the industry that a range of energies will need to be utilised in realising the target of reducing national carbon loads. As part of the UK plan to decarbonise domestic, commercial and industrial activities widespread electrification will become the major contributor towards reducing national and global carbon outputs.

Widespread electrification is a main objective by UK policy makers who aim to impose the cheapest electricity costs on UK households in the European region by 2035. Over the next 10 years electricity demand is predicted to double, by 2050 UK electrical demand and usage will be twice the amount that is consumed today.

To satisfy future electrical supply and demand the UK National Grid has announced plans for the “Great Grid Upgrade.” The national grid requires adapting due to a transition away from fossil fuels through electrification. The current UK grid was designed to transport coal fired energy generated from geographically positioned power stations.

Substantial amounts of energy consumed across the UK is now produced from areas that are situated away from the power stations. Offshore wind and solar energy is generated away from UK land, in rural and seaward locations. To cargo renewable energy across the UK means the construction of new electrical grid connections must be created to ensure easy distribution routes.

The total cost of the upgrade is thought to be around £16 billion (Fund Calibre, Yardley, 2024) and will include grid connections to offshore wind and rural solar installations that allows for the easy transfer of renewable power to all corners of Britain.

Further electrical grid connections and upgrade projects are being pursued that will also aid in the access of renewable energy to the UK electrical grid resulting in lower customer costs. The UK and Denmark have collaborated in constructing a link that stretches for 475 miles joining Lincolnshire and southern Jutland.

The Viking Link required £1.7 billion of investment and is capable of powering 2.5 million UK households. National Grid estimate that the new connection will result in £500 million of savings for UK customers in its first 10 years by enabling a clear path of trade that compliments seasonal demand and price between the two countries.

(all info available at National Grid website).

The UK and Netherlands governments have also announced plans to construct a submarine interconnection that will allow both countries to transfer and trade clean offshore wind generated electricity. The Lion Link will produce 1.8GW of energy – enough to power 2.5 million homes and is due to be operational around 2030. (Info available at National grid website)

Scottish Power will also upgrade their transmission network over the next 10 years costing £5.4 billion. These upgrades will contribute 80-85GW of clean renewable electricity to the British grid.

Significant work is being completed to adapting and connecting the UK transmission network to clean low-cost electricity. Domestic upgrades and submarine interconnections linking the UK with two additional countries should theoretically provide cost effective supplies of green power to UK businesses and homes.

Contractors, specifiers, system designers and installers should target manufacturers of decarbonising heating and hot water systems that have aligned their product options within future and current energy policy.

Rinnai will continue to provide UK customers with factual information that influences customer purchasing options with the aim of improving UK customer decision making in domestic and commercial decarbonising heating and hot water systems. Rinnai continue to monitor all domestic and global news related to all energy matters.

to take advantage of Rinnai design services and find optimum solution for your next project use our smart carbon calculation services

RINNAI’S H3 DECARBONISATION OFFERS PATHWAYS & CUSTOMER COST REDUCTIONS FOR COMMERCIAL,

DOMESTIC AND OFF-GRID HEATING & HOT WATER DELIVERY

CLICK HERE FOR MORE INFORMATION ABOUT H3

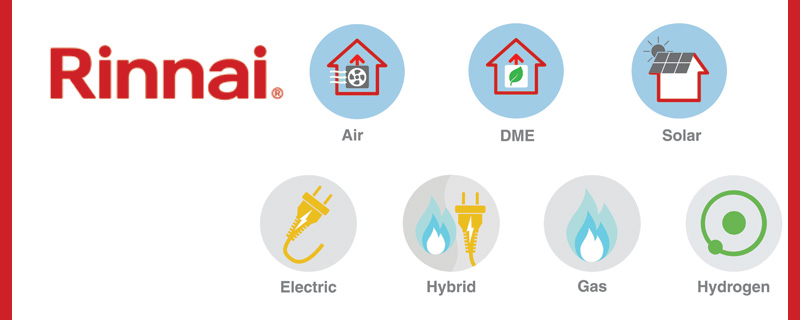

Rinnai’s H3 range of decarbonising products include hydrogen / BioLPG ready technology, hybrid systems, and a wide range of LOW GWP heat pumps and solar thermal. Also, within Rinnai’s H3 range is Infinity hydrogen blend ready and BioLPG ready continuous flow water heaters which are stacked with a multitude of features that ensure long life, robust & durable use, customer satisfaction and product efficiency.

Rinnai’s range of decarbonising products – H1/H2/H3 – consists of heat pump, solar, hydrogen in any configuration, hybrid formats for either residential or commercial applications. Rinnai’s H3 range of products offer contractors, consultants and end users a range of efficient, robust and affordable decarbonising appliances which create practical, economic and technically feasible solutions. The range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters.

Rinnai H1 continuous water heaters and boilers offer practical and economic decarbonization delivered through technological innovation in hydrogen and renewable liquid gas ready technology.

Rinnai’s H1 option is centred on hydrogen, as it is anticipated that clean hydrogen fuels will become internationally energy market-relevant in the future; Rinnai water heaters are hydrogen 20% blends ready and include the world’s first 100% hydrogen-ready hot water heating technology.

Rinnai H2 – Decarbonization simplified with renewable gas-ready units, Solar Thermal and Heat Pump Hybrids. Rinnai H2 is designed to introduce a practical and low-cost option which may suit specific sites and enable multiple decarbonisation pathways with the addition of high performance.

Rinnai H3 – Low-GWP heat pump technology made easy – Rinnai heat pumps are available for domestic and commercial usage with an extensive range of 4 – 115kW appliances.

Rinnai’s H3 heat pumps utilise R32 refrigerant and have favourable COP and SCOP.

Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

Rinnai’s commercial and domestic continuous flow water heaters offer a limitless supply of instantaneous temperature controlled hot water and all units are designed to align with present and future energy sources. Rinnai condensing water heaters accept either existing fuel or hydrogen gas blends. Rinnai units are also suited for off-grid customers who require LPG and BioLPG or DME.

Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours. Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question. Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s. More information can be found on Rinnai’s website and its “Help Me Choose” webpage