Rinnai has produced a new CPD titled ‘Water Neutrality’ and it details a subject that will become increasingly important as UK water supplies become less accessible due to overpopulation and climate change. Rinnai aims to increase awareness of this issue as well as supply verified information and industry insight into the question: should water neutrality be added to national legislation?

This recent addition to the company’s extensive list of industry relevant CPDs including ‘SPF – Seasonal Performance Factors and Heat Pump Design’; ‘Retrofitting Heat Pumps into the Leisure Sector through CCA & SPF Analysis’. And now the ‘Introduction to Water Neutrality.’

Sign up today as places are limited at and see how you can earn and learn bursaries of up to £200 on successful completion of all three CPDs.

All the CPDs provide updated insights into significant issues concerning contractors, consultants, specifiers, system designers, and installers operating in the UK HVAC market.

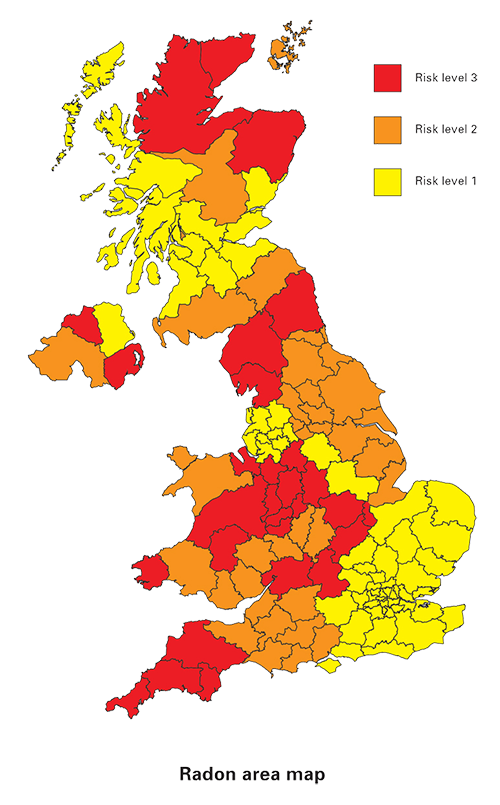

Water neutrality specifically relates to the construction of developments that do not increase the amount of water being extracted from local water supplies. Property & buildings construction, as well as the HVAC industry, are now open to a new field of criteria that could affect a new project’s viability.

Water neutrality aims to ensure building developments are planned and completed as to not increase water consumption in the surrounding area. Water neutrality aims to achieve this aim by reducing water use, reusing water and offsetting water demand.

Rinnai’s new CPD presents the three key stages of achieving water neutrality and highlights reducing water usage as opposed to offsetting water usage. The ‘Water Neutrality’ CPD then leads into a case study which focuses on reducing water usage during the refurbishment of a commercial building and demonstrates several direct and indirect benefits on water consumption, cost and carbon production.

Rinnai’s aim with this CPD is to inform the audience of:

How the water neutrality process can be applied to both new developments and refurbished buildings.

Providing information on each step of water neutrality, methods of successfully completing each step as well as the benefits and disadvantages.

A case study application verifying the benefits of adopting a water neutral approach and the range of benefits this can have on performance, cost and carbon.

Rinnai UK’s new division – Rinnai Applied – is also offering an opportunity to gain bursaries of £200 when those eligible successfully complete three specific CPDs.

The CPDs are on the following subjects:

Seasonal Performance Factors (SPF) and Heat Pump Design

Introduction to Water Neutrality

Retrofitting Heat Pumps into the Leisure Sector through CCA & SPF Analysis

Rinnai continues to inform the UK market of system operating details that provide an accurate statement of system performance, while considering the effects on operational expenditure, economic investment, and environmental impact.

RINNAI OFFERS CLEAR PATHWAYS TO LOWER CARBON AND DECARBONISATION

PLUS CUSTOMER COST REDUCTIONS FOR COMMERCIAL, DOMESTIC

AND OFF-GRID HEATING & HOT WATER DELIVERY

click here to learn more about Rinnai

- Rinnai’s range of decarbonising products – H1/H2/H3 – consists of hot water heating units in gas/BioLPG/DME, hydrogen ready units, electric instantaneous hot water heaters, electric storage cylinders and buffer vessels, a comprehensive range of heat pumps, solar, hydrogen-ready or natural gas in any configuration of hybrid formats for either residential or commercial applications. Rinnai’s H1/2/3 range of products and systems offer contractors, consultants, and end users a range of efficient, robust, and affordable low carbon/decarbonising appliances which create practical, economic, and technically feasible solutions.

- Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

- Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours.

- Rinnai offer carbon and cost comparison services that will calculate financial, and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question.

- Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s.

- The Rinnai range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

CLICK HERE TO VISIT THE RINNAI WEBSITE

or HERE to EMAIL RINNAI

CLICK HERE For more information on the RINNAI product range