UNVEILING THE TRUE MEANING OF VALUE ENGINEERING IN COMMERCIAL HOT WATER

Rinnai has released another whitepaper – “Optimizing Domestic Hot Water Systems for Archetype Care Homes: A Value Engineering Approach” which, within the main body of the analysis, is a case study demonstrating the optimal solution for DHW provision in an archetype care home with specific requirements including a 20% reduction in carbon footprint, OPEX considerations and available space for only 2 heat pumps.

CLICK HERE FOR THE RINNAI HELP ME CHOOSE A PRODUCT PAGE

There are five main solutions presented in this case study for optimal DHW requirements in an archetypal care home:

- Electric immersion cylinders

- Heat pumps

- High efficiency gas water heaters

- Hybrid system comprising of 20% heat pump and gas water heaters

- Hybrid system comprising of 40% heat pump and electric immersion cylinders.

Due to the requirements of the care home and assessing all possibilities against the pre-determined criteria, solutions 3,4 and 5 were viewed as being worthy of further analysis.

Step 4 of the value engineering methodology proposed by Rinnai UK, analyses solution against the current installed system of three non-condensing storage water heaters.

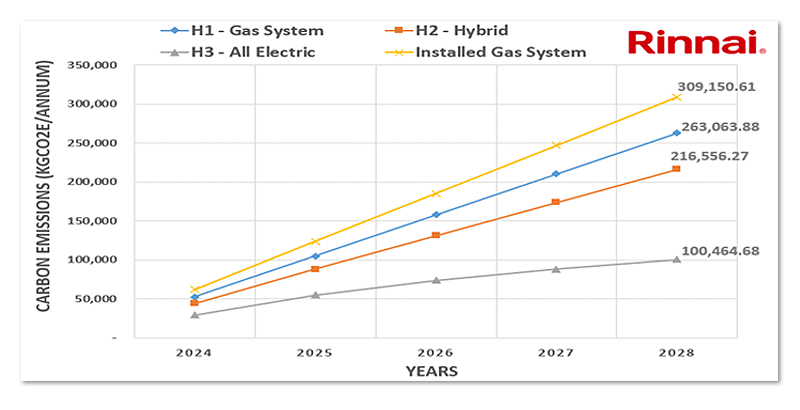

Figure 1 showcases the carbon performance of solutions 3, 4 and 5 as well as the currently installed system of three storage heaters. The colours of each system are highlighted at the top of the graph in blue (Solution 3), orange (Solution 4) and grey (Solution 5).

Figure 1: Carbon Emissions forecasted over 5 years.

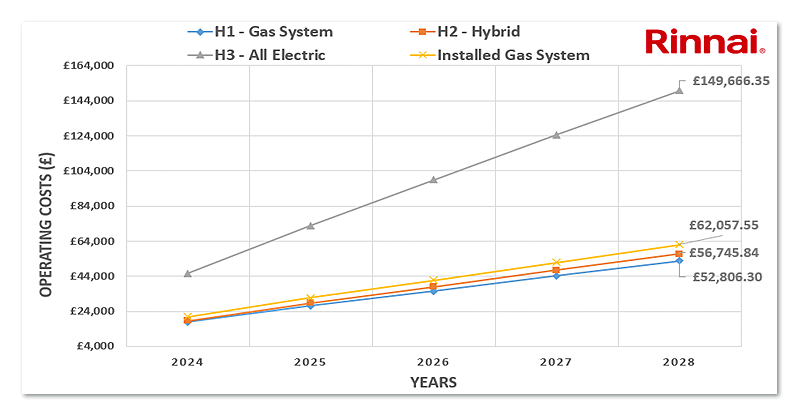

Figure 2 shows operating costs over 5 years for all three solutions (blue, orange and grey) and the currently employed gas storage system (yellow) is also provided below. Solution 3 highlighted in blue, the gas system costs £52,806. Solution 4, the hybrid system will cost £56,746, whilst solution 5, the all-electric system costs £149,666.

Figure 2: Operating costs forecasted over 5 years

Of note is the costs of electricity in the UK which are being targeted by the government to fall by 2035 and be an integral part of cleaning the grid – and note that Figure 2 utilizes Govt forecast statistics.

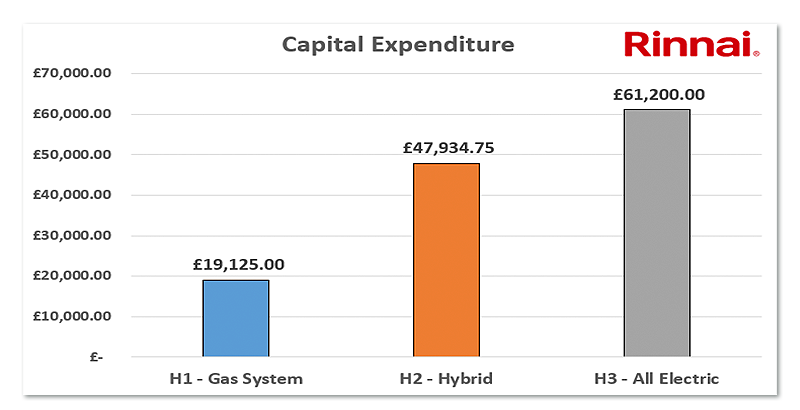

Figure 3, below, is a graph that illustrates the CAPEX costs associated with each solution. Solution 3 (blue), high-efficiency gas water heaters will cost £25,500. Solution 4 (orange), the hybrid system comprising of 20% heat pump and gas water heaters costs £63,913 and finally, solution 5 (grey) the all-electric system comprising of 40% heat pump and electric immersion cylinders will cost £81,600.

Figure 3: Capital Expenditure required for each solution

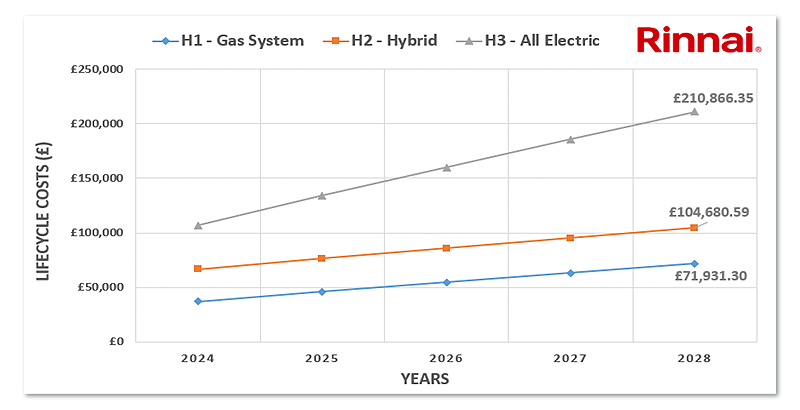

Figure 4 is the final graph that gives the 5-year life cycle costs associated with each system. Solution 3, the gas system (blue) will cost £78,306. 30. Solution 4, the hybrid system (orange) will be £120,658.54. And finally, Solution 5 (grey) – the all-electric system will cost £231,266.35.

Figure 4: Lifecycle costs forecasted over 5 years

Therefore, the decisive question for the site is whether the reduced carbon emissions of Solution 5 is perceived as far more valuable than the lower lifecycle costs of Solution 4.

Due to the customer’s brief of requirements to include: –

- 20% reduction in carbon footprint

- OPEX considerations

- space for only two heat pumps –

The optimal solution for DHW provision is the hybrid system that includes the 20% heat pump and gas water heaters. It delivers reduced carbon emissions and financial expenditure and can operate within a space limited environment.

Rinnai aims to demonstrate to specifiers, consultants and system designers that the company’s technology provides practical, technical and economic solutions for businesses and sites who wish to significantly reduce their carbon emissions.

RINNAI OFFERS CLEAR PATHWAYS TO LOWER CARBON AND DECARBONISATION PLUS CUSTOMER COST REDUCTIONS FOR COMMERCIAL, DOMESTIC AND OFF-GRID HEATING & HOT WATER DELIVERY

- Rinnai’s range of decarbonising products – H1/H2/H3 – consists of hot water heating units in gas/BioLPG/DME, hydrogen ready units, electric instantaneous hot water heaters, electric storage cylinders and buffer vessels, a comprehensive range of heat pumps, solar, hydrogen-ready or natural gas in any configuration of hybrid formats for either residential or commercial applications. Rinnai’s H1/2/3 range of products and systems offer contractors, consultants and end users a range of efficient, robust and affordable low carbon/decarbonising appliances which create practical, economic and technically feasible solutions.

- Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing products that offer high performance, cost efficiency and extended working lives.

- Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours.

- Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question.

- Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s.

- The Rinnai range covers all forms of fuels and appliances currently available – electric, gas, hydrogen, BioLPG, DME solar thermal, low GWP heat pumps and electric water heaters More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

Leave a Reply

Want to join the discussion?Feel free to contribute!