Visqueen keeps methane at bay

A water pumping station built to provide a vital back-up supply for Birmingham is being protected from an ingress of potentially deadly methane by Ultimate GeoSeal, the waterproofing and gas protection system from Visqueen.

The station at Lickhill near Kidderminster draws water from the River Severn which is then pumped over 16 miles to Frankley treatment works, south of the city.

It was commissioned by Severn Trent Water so that the Elan Valley aqueduct that normally supplies Birmingham could be closed for annual maintenance, and also to provide an alternative water source in an emergency.

The Lickhill station is in an area where methane in the ground was a concern and, as a consequence, the project was classified as a Characteristic Situation 2.

James Walsh, Technical Support Manager for Visqueen, explained that coming up with a suitable gas protection and waterproofing solution for such a challenging scheme involved more than just specifying the right product. It also required a high level of technical knowledge and design expertise.

“While having an in-depth understanding of the industry guidance and regulations is essential, it also requires an understanding of construction methods and build sequencing, and being able to offer a professional judgement that can only be gained from experience,” he said.

“Stopping harmful gases and contaminants from entering a building is a human health issue, and, therefore, the Visqueen technical team had a massive responsibility to ensure the building and its occupiers are safe.”

The design team was mindful of the Abbeystead disaster in 1984, when methane ignited at the Lancashire hamlet’s water pumping station, leading to the deaths of 16 people. Industry guidance and regulations have been written since then to support gas protection designers when designing such schemes.

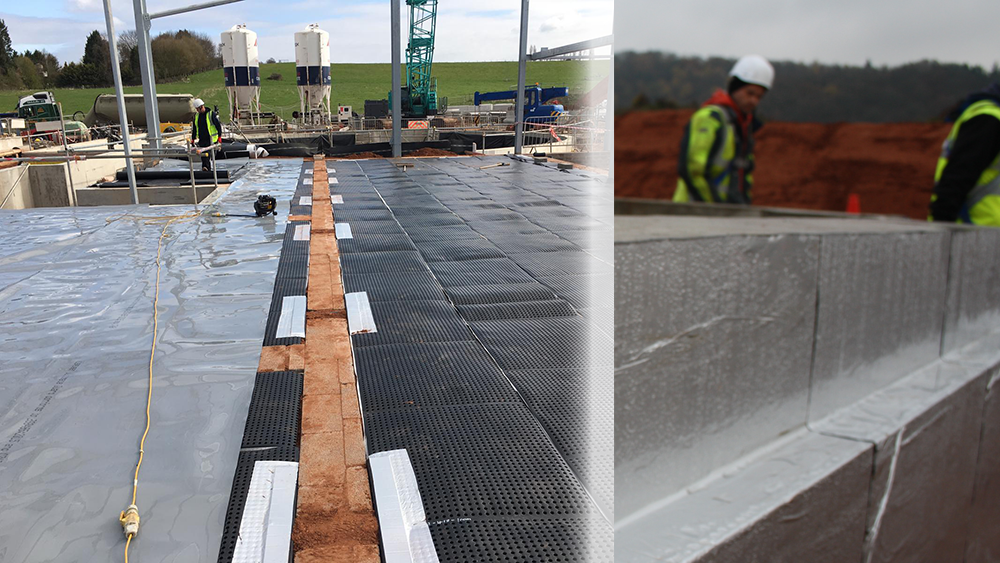

Visqueen Ultimate GeoSeal is a pre-applied membrane and for Lickhill it was used not only for its gas resistant properties but also for waterproofing, as the 16-metre deep main pumping station shaft passes through the water table, also known as the saturated zone.

The membrane was applied to the piles extending 18m below ground level and also to the 12-metre diameter base of the shaft.

James added: “Robustness is also of key importance for demanding civil applications such as this as the membrane, which is twice the thickness of competitor products, must remain intact for the lifetime of the structure.”

Visqueen Ultimate VOC Blok, a flexible membrane suitable for brownfield applications which forms a barrier to volatile organic compounds and ground gases, was applied below the concrete slab and pre-cast planks of a number of support buildings.

Positioned at ground level, the specification for these buildings also required an under-slab ventilation system to exhaust and disburse to atmosphere any harmful gases present under the building. This was achieved with a full vent blanket using Visqueen Gas Vent Matting and Pro Gas Vent Boxes.

The main contractor on the project was Barhale plc, with Nicholas O’Dwyer the engineering and environmental consultant and Prestige Air Technology the installer. Independent verification in accordance with CIRIA C735 was by ASL Environmental.For further information on gas prevention and waterproofing solutions, or to arrange a CPD presentation, or to attend a gas protection workshop, visit www.visqueen.com.

Leave a Reply

Want to join the discussion?Feel free to contribute!