Leading physical security specialist, Securikey, has made innovative modifications to its range of Modulprim security rooms. The Modulprim is a bespoke modular vault solution for both new builds and existing buildings and is a convenient and cost effective method of adding a high security strong-room to a building. The Modulprim offers a complete storage facility for money, documents and pharmaceuticals and is adaptable to most building specifications, even those with limited space or those located on upper floors. This impressive level of adaptability has now been increased further with the introduction of new lighter-weight materials to offer even further convenience and more storage space.

Securikey’s Modulprim components have now been adapted, using new materials, to provide further options, ease of installation and accessible space. New light-weight panels combined with reduced steel work decrease the weight of the original Modulprim by up to 25%. In addition, the new method allows for unsupported space of up to 12 metres with no internal pillars, compared to 7.4 metres on the original, providing the customer with a much greater amount of useable space along with increased flexibility in layout.

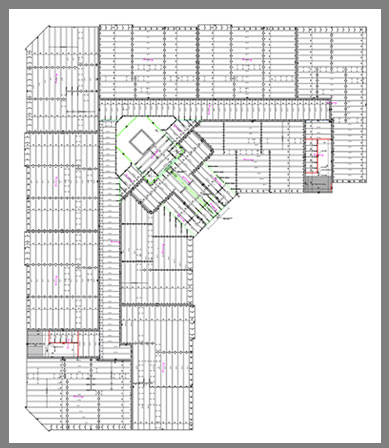

Pre-fabricated off-site to precisely fit a detailed floor plan drawn up by Securikey, the Modulprim components are welded together from smaller panels allowing installation in difficult to reach locations which means that it can be easily modified at a future date and it is also possible to disassemble the vault and transfer it to another location.

The Modulprim can be installed on any floor capable of taking the minimum load capacity, the scope of which has now been widened with the introduction of the new lighter weight components and, although extremely robust, the walls are relatively small in width enabling the Modulprim to be installed in more compact areas without compromising on security.

Consisting of four walls, a floor, celing and vault door as standard, the Modulprim can also be supplied as a five sided solution if desired, as is often a requirement for the pharmaceuticals market. The Modulprim door, which is manufactured from steel and delivers a level of protection that is equal to or higher than the vault room itself, is available in Grades ranging from 0-9 depending on the level of security required. All vault elements are subjected to exhaustive tests to meet European security standard EN1143-1, ensuring European wide approval and, in addition, each product is branded with the appropriate badge as proof of certification – the Modluprim also has the approval of SBD (Secured By Design), the official UK Police flagship initiative combining the principles of ‘designing out crime’ with physical security.

As testimony to Securikey’s reputation for efficient and user-friendly products, the unique construction of the Modulprim also allows for the space above the Modulprim to be used for storage of up to 500kg per square meter if required, meaning that not an inch of space is wasted.

For more information about Securikey’s Modulprim or to download the latest strong-room catalogue, visit www.securikey.co.uk/vaults-and-safe-deposit or call 01252 311 888.

SCS commented on the Abbey Foregate job “We recently used Posi joists supplied by

SCS commented on the Abbey Foregate job “We recently used Posi joists supplied by